Precision Laser Cutting

High Precision Laser Cutting

This type of laser cutting is the most successful and effective practice to achieve quality clean edges and superior products. As opposed to more traditional methods (water jets, punches), laser cutting for your project allows the material to be processed with extraordinary accuracy and without any other interventions to get a finished piece. It also allows for less waste and is less time consuming, resulting in cleaner production and the ability to manufacture in greater quantities. For additional information, please review, “Laser Equipment Review“, page. No matter how complex or straightforward, we achieve the precise, fine cut, details your company needs.

A sampling of the work we produce includes laser cutting processes such as ablation, drilling, and depaneling. We utilize UV, CNC, and Infrared lasers on both metal and non-metal materials that result in detailed features with finely cut precision parts during the manufacturing process.

A-Laser has the equipment, expertise, and quick turn capability to provide our laser cutting service customers with precision laser-drilled panels of the highest quality in the shortest time.

We provide a variety of precision laser processes such as marking, etching, and skiving, and even prototype manufacturing. We pride ourselves on delivering state of the art products by highly educated technicians and continue to research and adopt new technologies all to ensure our customer’s satisfaction.

As a leader in the industry, A-Laser offers precision parts manufacturing for a wide variety of trades including medical, engineering, and electronics. We provide our customers with high-end results resulting in state of the art products by using the latest technology by our skilled technicians. The manufacturing industry is an ever-changing one and we continually explore and implement new advancements to ensure consumer needs are met. Our goal is to deliver quality, innovative products and provide a commitment to excellence in a competitive field.

Precision Parts for Precision Industries

Many of today’s industrial manufacturers depend on extremely tiny and complex parts to assemble their large projects. In the precision manufacturing industry especially; small, intricate parts such as nuts, bolts, shims, fasteners, and washers are essential to assembly. One of the largest manufacturing industries in the world is the aerospace industry. For both civil and defense sectors of aerospace, precision is essential when manufacturing products that fly through our skies and solar system. There is absolutely no tolerance for error in aerospace design and manufacturing, and precision parts contribute to reducing that error.

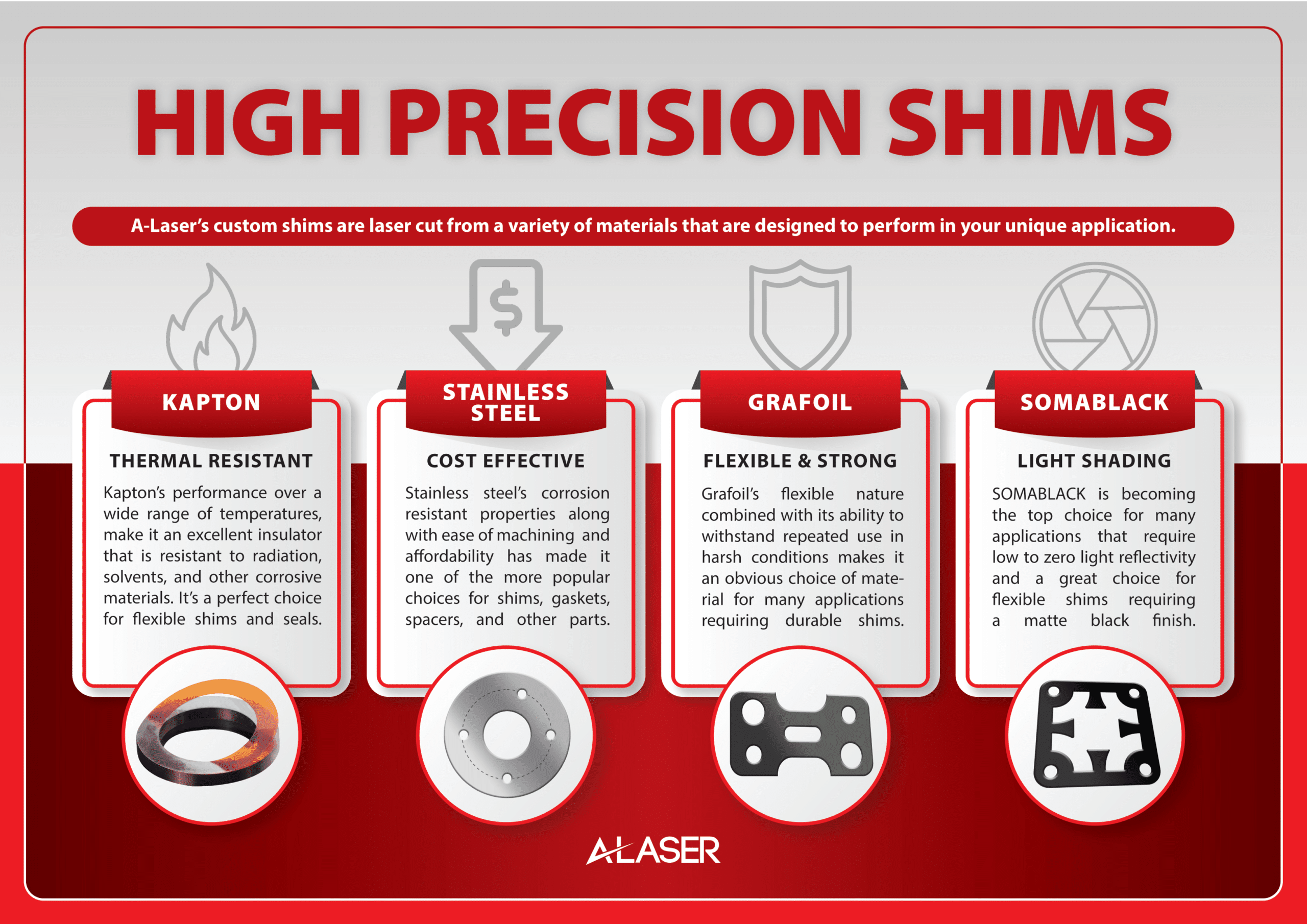

At A-Laser, we utilize the most advanced infrared lasers in the world while specializing in precise cutting and processing of ultra-thin materials such as plastics and metals. Some of the parts we process are shims and washers specifically designed for the aerospace industry. A-Laser produces shims and washers that follow specific and strict design requirements allowing for exact control over materials, tolerance, quality, quantity, size, thickness and shape. The primary purpose of washers is to distribute the load, act as a spacer, and to serve as a locking mechanism. Washers are also important in the prevention of Galvanic corrosion, which is caused when one metal begins to corrode during electrical contact with another metal. This can be prevented by using the washer as a separator and neutralizer between the two metals.

In aerospace, washers can also serve as shims used to fill small gaps or spaces between parts. It can also be used to support and adjust or to provide a level surface especially for parts that are subject to wear. These parts must be precisely cut considering they are used whenever an adjustment is needed in order to keep measurements accurate. They are frequently used in order to compensate for inaccuracies or other inconsistencies within a project. Washers and shims cut using A-Laser’s precision lasers are guaranteed to be consistent with your specific design requirements. Precise engineering, precise design, and precise manufacturing are all essential for success in a precise industry.

At A-Laser, we know that our customers demand high-quality complex parts. We also know that our customer’s success depends on our ability to deliver these high-quality parts as quickly as possible. We are able to deliver prototypes and low volume runs within 24 hours and higher volumes within a few days.