Laser Skiving

Laser Skiving for Selective Removal of Material Layers

Skiving means to slice and is used on a variety of materials. For metals, skiving can be used to remove selective thin layers without affecting the material it comes off of, exposing the underside for handling, and can also create thin slices on existing substances.

Laser skiving is frequently utilized in the manufacture of tooling and molds and can be a great solution for technology in industries like electronics manufacturing and semiconductor.

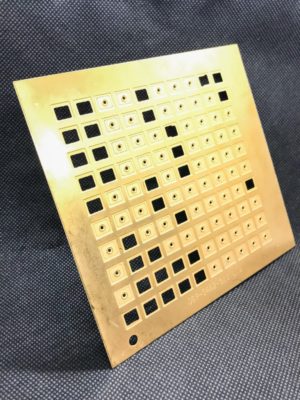

Our UV laser technology can accomplish trimming resistors or marking parts through the controlled and selective removal of thin layers of material. Laser skiving benefits include the production of consistently arranged geometries in material surfaces and can even induce specific changes to the surface’s technical properties. In these instances, one single element often measures only a few micrometers.

Products such as hydraulic cylinders, gas tanks, transformers, and even seatbelts all use laser skiving technology in their development process.

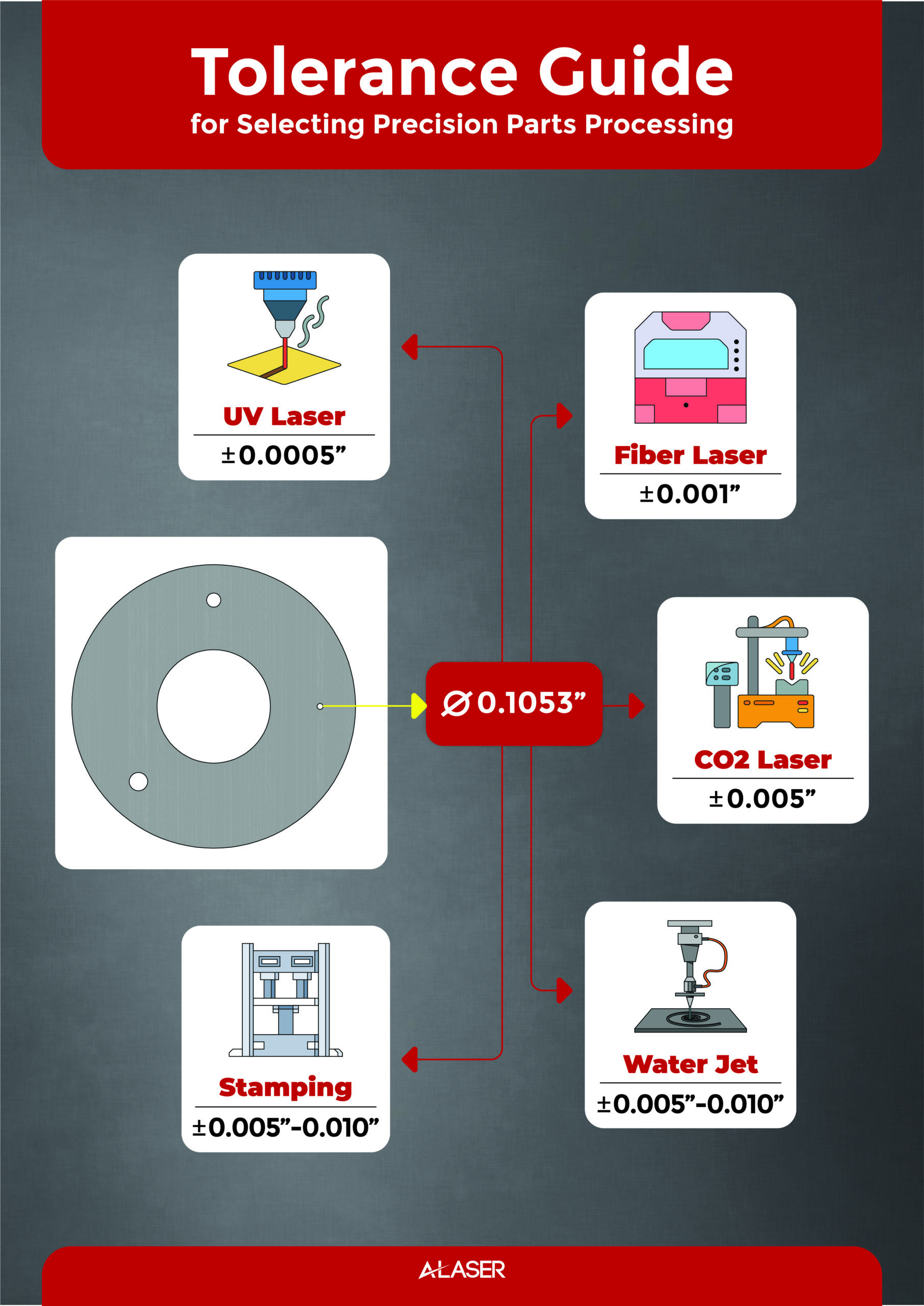

A-Laser’s highly skilled technicians use skiving cutting services with UV (ultraviolet) laser equipment. Using a UV laser with a <20 micron beam as opposed to another type gives us the ability to work in extremely fine contours.

The main benefits are then passed on to our customers with a clean, consistent trace left on the products, with all carbon residue having virtually been eliminated. This improves your products’ functionality and efficiency that will enable them to work at the highest level possible.

Our customers will also benefit by finding savings in time and money with our skiving process as it also reduces post-process cleaning. A-Laser laser skiving service is precise to 12 microns, meaning there is a reduction in product fallout, which creates a difference in your bottom line.

Laser skiving is an excellent choice for:

- Repeatability, speed, and precision

- High production volumes

- Minimal part distortion

- Consistent depth and width control

- Cost-effectiveness

- Dissimilar metal applications

PCB Laser Skiving

Laser Skiving is an excellent solution for the electronics industry. A-Laser PCB laser skiving services can be utilized on both rigid and flexible circuit board designs. In this application, we employ UV lasers for the controlled removal of materials such as polyimides or coverlay materials. In terms of flexible circuits, our technology is capable of Kapton skiving or copper pad exposure, especially when it is too small for options like drilling. Rigid circuit PCB laser skiving applications may include dry films and solder mask removal to cavity formations. UV lasers also have the ability to ablate metal layers to create traces on a PCB where fine contours are required.

PCB dielectric material can be completely cleared with laser skiving, or stopped before cutting all the way through, which is a process known as controlled depth. When controlled depth is required without landing on a metal, the depth tolerance and surface topography is a function of the material. There will be less variation in depth tolerance if the dielectric is more homogeneous.

Why work with A-Laser?

By integrating broad process capabilities such as CNC laser cutting, precision parts manufacturing, laser marking, laser depaneling, laser drilling and micromachining, skiving, and routing with various laser cutting frequencies. A-Laser is delivering innovative products that address complex design requirements.