Laser Cutting Services A-Laser delivers on the most demanding technical projects.

Our expertise and commitment to working with our customers has enabled A-Laser to continue to grow our laser cutting services and cement our reputation for high quality precision laser cutting of extremely challenging materials. Through our location in Milpitas, California, industries that demand continued reliable and repeatable production, but also have support requests for R&D and NPI, have sought the services of A-Laser.

Why work with A-Laser?

By integrating broad process capabilities such as CNC laser cutting, precision parts manufacturing, laser marking, laser depaneling, laser drilling and micromachining, skiving, and routing with various laser cutting frequencies. A-Laser is delivering innovative products that address complex design requirements.

A-Laser Capabilities

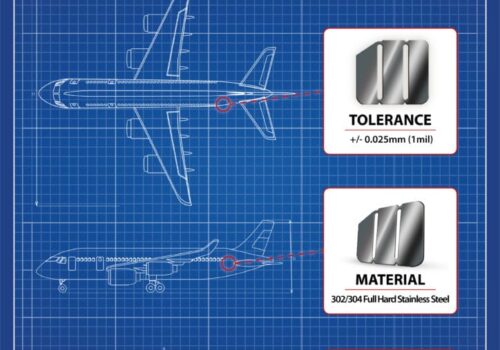

- We currently utilize state-of-the-art UV lasers. These incredible systems offer tolerances of +/- 25um, with 13um available for custom projects. Custom laser cutting has never been better.

- UV laser’s ability to cut materials such as: Kapton, Peek, Grafoil, Q-Pad, Stainless Steel, Copper, Beryllium Copper, Alumina Ceramic, FR4, Acrylic Adhesive, Brazing alloys, and many more.

- Metal Laser Cutting Service – Using IR lasers, Stainless Steel alloys, from .004” up to ,025” mils thick. Other metallic alloys as well. This method is often sought after by industries such as Medical Device, Industrial Nozzle applications, Aerospace, Defense, National Labs and so on.

- Experience staff of Engineering and CAD to support custom projects.

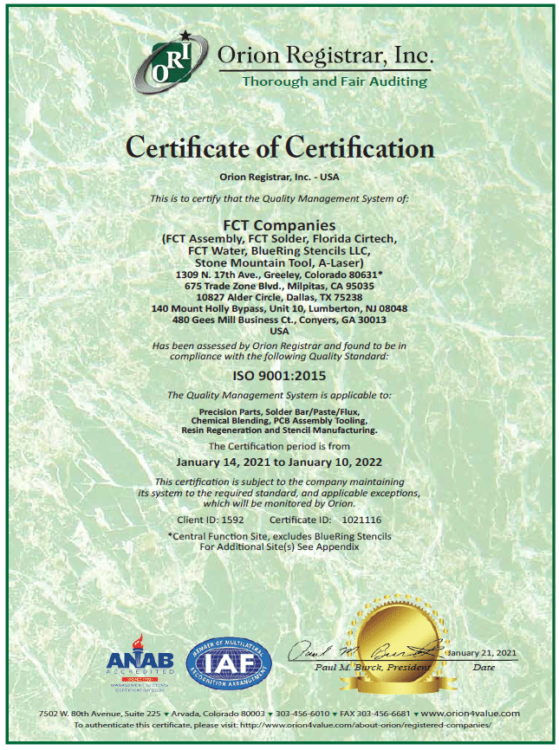

- Quality Assurance backed by OGP systems. Allowing A-Laser to handle AQL level inspection requirements.

- Laser Cutting services California! Our location services customers worldwide. Many have R&D in the Bay Area and in California. This has become a plus for many seeking onsite Laser Development support.

Benefits to Our Customers

- Our precision laser cutting systems used have a kerf of 20um(UV) and 35um(IR). These small diameters allow for precise profiles to be cut.

- No long wait for tooling. Laser technology cuts from the data files.

- Nesting of material to reduce waste

- Ability to support R&D and Production level jobs. Cutting 1 or 100,000 is not an issue!

- Onsite Laser Development- Seeking to work one on one with our engineering and CAD team? A-Laser works with customers as a team and our goal is customer satisfaction.

Additional Services Offered

Laser Depaneling

A-Laser is proud to have laser depaneling services in house. We work directly with contract assembly manufacturers’ who require tighter precision over conventional router bit methodology. Our precision laser cutting system allow for tighter, cleaner cuts to the PCB edge and does not add stress to on board components. Offers the ability to nest boards closer due to the 20um kerf. Expands the design options to the layout of the PCB profile. All work both NPI, R&D and full production runs are processed in Milpitas California location and processed in an ESD safe environment.

Laser Ablation

Laser ablation is often requested to remove a substance off the surface while keeping the underlying materials intact. A-Laser has a great amount of experience creating the right tools to solve these challenges.

Remote Laser Development

Our customers do not need to be onsite for us to develop a process, much of this work is done remotely. Communication including updates with images, QA reports and samples. If there is a way, we will find it.

Proceed with Confidence

- Trusted in our capabilities include customers in: Semiconductor, Medical Device, National labs, Energy, including Battery and Solar, Textiles, Adhesive Application, Contract Manufacturers and numerous more.

- We work with many start-ups and understand the time needed until a project can launch. We are here to support short and long term.

- Confidentiality is a must with many customers, so signing an NDA is welcome.

- Our staff is trained yearly and our machines are calibrated at scheduled intervals.

- We are ITAR registered and work with many companies directly in defense contract support.

Think Outside the Box

Custom laser cutting technology compared to other methods like Chemical Etching, CNC, Wire EDM, Stamping, Die Cutting, exceeds many of the levels of quality to the forementioned. When your project requires more precision and the material is just not manufacturable, seek out laser technology. Call or email A-Laser and we will be happy to review your project and advise. If our laser services are not the best fit, we will try and guide you to the best option.