Laser Depaneling with A-Laser

Let us show how laser depaneling can be superior to traditional depaneling

Why laser depaneling?

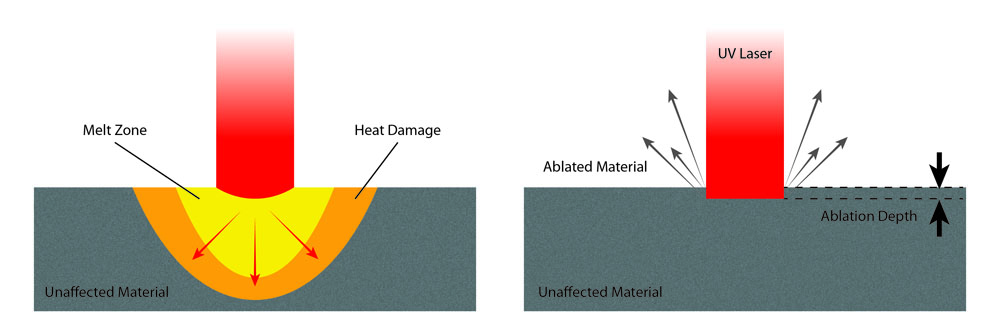

Laser depaneling is a fast-growing portion of our overall laser cutting services due to A-laser’s high cut quality, quick turn capability, and unmatched material handling the experience. Our UV cutting systems use laser ablation to process materials, thus vaporizing rather than melting which creates a clean, burr-free edge and leaves virtually no carbon residue.

Therefore, circuit failures and extra cleaning processes are greatly reduced with laser ablation; offering significant cost savings for laser depaneling.

Clean and reliable PCB depaneling has been done by mechanical routers, dicing saws and pizza cutters for a long time now. Alas, just like everything else related to technology, those technologies are dying out and becoming obsolete mainly due to new electronic components becoming more complex and sensitive to vibration or contamination, so maybe it’s time to put down that chainsaw and embrace the future!

How much is Laser Depaneling?

Laser depaneling is often more cost effective than traditional depaneling methods – especially when you take the risk of circuit failures and a reduction in the time needed to clean and prepare the boards.

We’re happy to get you a customized quote for your depaneling needs. Fill out the form and one of our sales team will be in touch within 24 hours.

*Our quotes are zero obligation. Let us show you how Laser Depaneling can help you save money on your depaneling projects.

Get a free quote for your depaneling project.

What are the benefits of laser depaneling?

Our laser ablation process creates numerous benefits for our customers that are not quite as obvious:

<20 micron beam size

Allows tighter parts spacing meaning material cost savings

Push right up to the edge of the board

Low thermal influence

High precision cuts

(+/- .0005″)

Adds greater reliability

Contact-free ablation

Ensures the integrity of your panels during depaneling process

Other benefits include no vibration or mechanical stress on solder joints, no fixture or minimal fixturing requirements for unloaded panels, a clean dust free environment, and the ability to depanel flex circuits quickly and cleanly regardless of the stack-up.

How does laser depaneling work?

Laser ablation for depaneling services is CAD driven which allows for immediate implementation of design changes and laser beams don’t dull or chip, which means there isn’t the added expense or time wasted waiting for hard tools. We are aware that little details, such as wearing proper gloves to avoid oil from fingertips, can have a huge impact post cutting processes and make sure our entire laser cutting group are trained to know the handling requirements of our customers.

Our Experts Can Help

We have years of experience singulating panels and chips for a wide range of applications. The key is communication so we take the extra steps to be certain our customers receive the best laser cut product available.

Laser routers come in all shapes and sizes but we have the best technology. Our LPKF UV laser machines will give you the best bang for your buck. Especially with the newest addition to our brigade of machines the MicroLine 5820. This serious piece of equipment turns de paneling into a game of Fruit Ninja, it’s faster, cleaner and stress-free, both for you and your boards!

Laser ablation has become a key component in higher and more reliable performance of electronics components. We always strive to outperform and raise the bar for laser cutting, laser routing, laser micromachining and post process services in today’s market.