Laser Cutting Tolerances Precision Laser Cutting

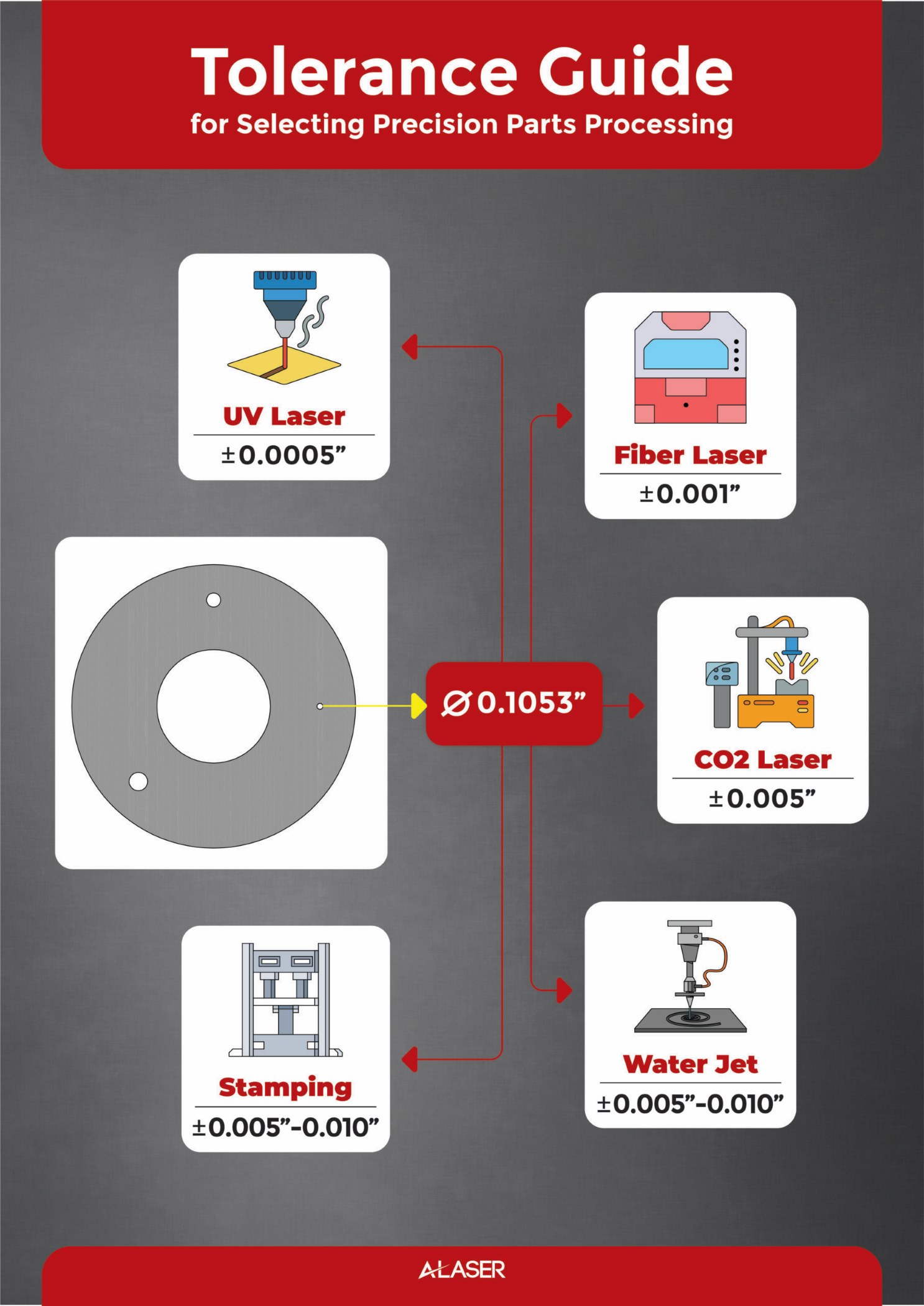

Selecting Precision Parts Processing

UV laser machines work cleanly to achieve precise cuts. As industries are demanding smaller and smaller parts, the demand for processes that can achieve tight tolerance is only increasing, and UV lasers are perfectly positioned to meet this need.

When it comes to precision laser cutting quality, precision parts need to pass both visual inspections and dimensional inspections based on the print’s requirement. To be acceptable, parts need to fit within the dimensions specified in the print.

In the laser precision cutting world, tight tolerance is defined as the acceptable amount of variation when a part is being processed. Designs that call for precise dimensions require a machining process that can rise to the demands.

The following are the tolerance that can be achieved for various technologies:

- Stamping: +/- 0.005” (NW4S Inc), +/- 0.010”

- Waterjet: +/- 0.005”-0.010”

- Fiber laser: +/- 0.001” (stainless steel mostly)

- CO2 Laser: As low as +/- 0.002”

- UV Lasers: As low as ±0.0005″

Achieving such precise tolerances has a lot to do with materials, thickness, and the process used.

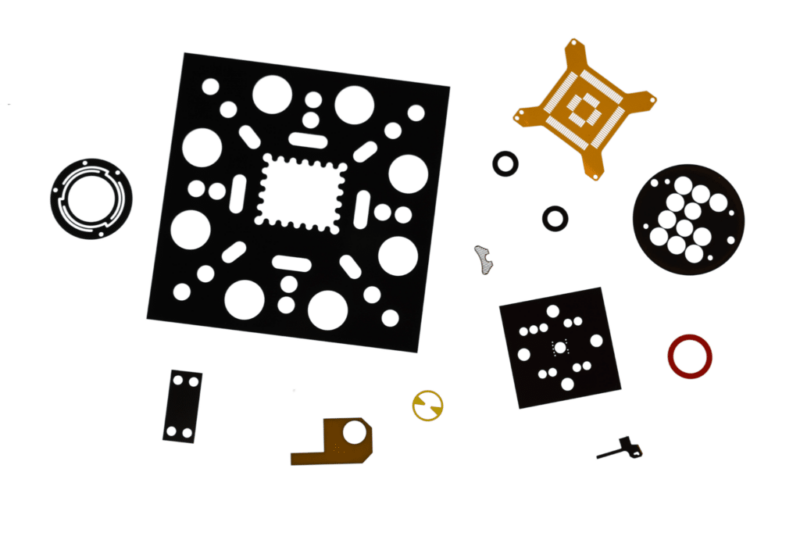

A-Laser Precision Laser Cutting

In the machining world, there are three deciding factors to move forward with any project

PRICE

TIME

QUALITY

Why Expert Engineering Matters

There’s a common misconception that tight tolerances can be achieved by using a specific laser machine, and that’s all there is to it. In truth, success relies on more than just choosing the right machine. While the machine has a major effect on the result, precision also requires engineering expertise to get the right results.

At A-Laser, we understand that expert knowledge is the key to getting projects run right. Our engineering department has an excellent team that can come up with the best solution to meet your print requirements.

Why? Because they are experts in CAD adjustment, tool engineering, and setup.

Our quality control department is ISO:9001 certified and has the right measuring machines to verify the dimensional result. If they don’t pass the test, we send the parts for re-evaluation and re-processing.

In other words, we have the expertise to do the job right and to prove that the final result lives up to your expectations.

A-Laser excels in quality where others fail by measuring tight tolerances and achieving true position, calculated mathematically.

Why is achieving tight tolerance critical?

In all industries, customers are demanding smaller products with more features. Fitting these smaller custom parts is why using tolerance is such an important tool, making the finished product smaller and more efficient.

Adding to that, tolerance optimization during design has a positive impact on the yields coming out of manufacturing. Optimizing yield makes for high-quality, safe products built with smaller, more efficient parts. It also cuts down on cost and allows manufacturers to focus on the things that really matter, rather than paying for failures.