Fiber Laser Cutting Services

In just a few short years, the use of fiber lasers as the newest cutting technology for flat metal sheets and plates has risen exponentially. Fiber lasers have achieved in five years the cutting threshold that took CO2 lasers 4x as long to reach. A fiber laser’s wavelength classifies it as an Infrared (IR) laser.

Fiber laser cutting technology has revolutionized the entire industry because it impacted every level of sheet metal fabrication. The opportunities were easy to realize and continue to expand. As fiber lasers grew to the popularity they have today, the industry was learning the benefits and possibilities of the technology.

At first introduction, fiber lasers’ primary attraction was the lower operating costs, due to no maintenance to the source. Today we see even more benefits to using fiber lasers.

Our A-Laser team has found fiber lasers to be extremely useful across a wide range of applications, including use in medical devices and electronics.

Why use fiber lasers?

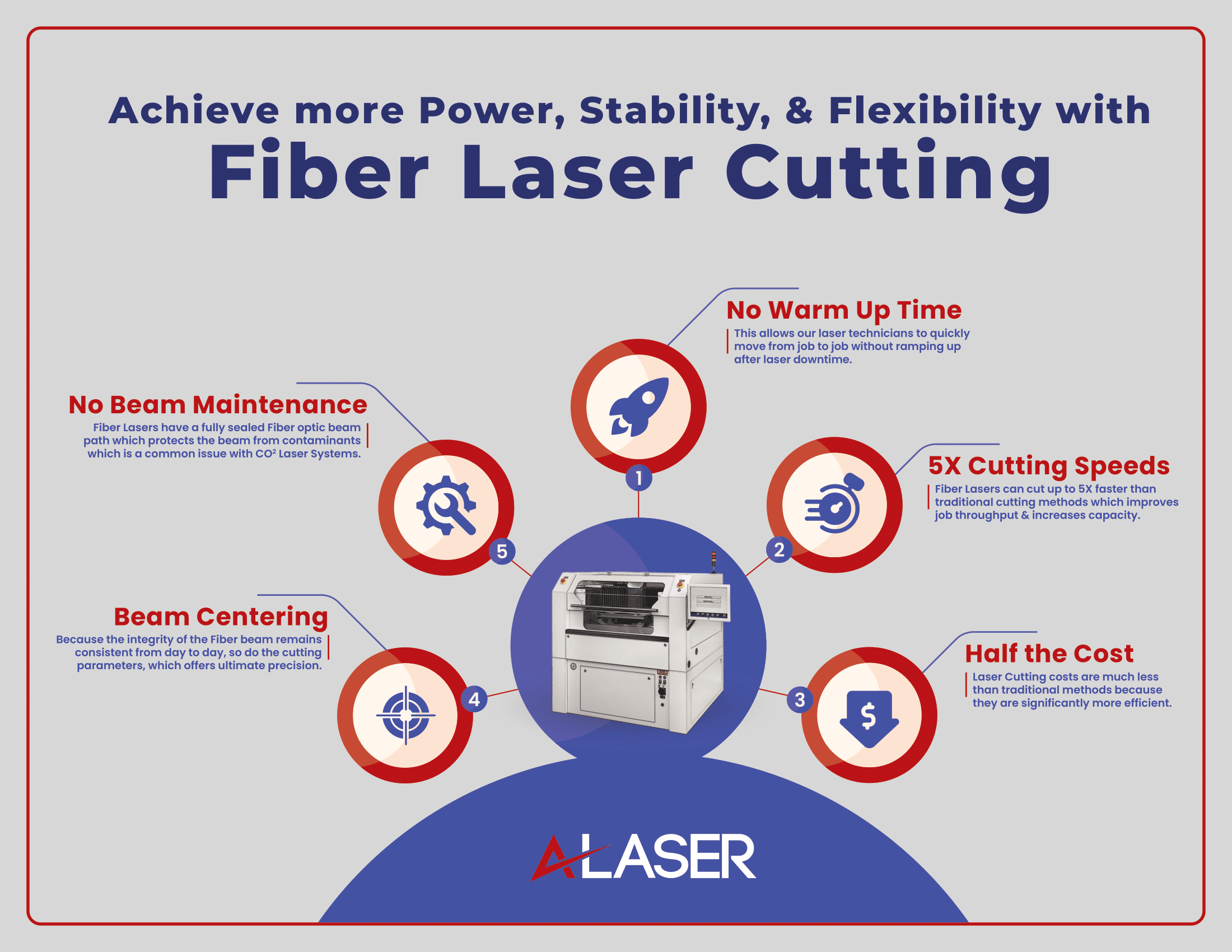

The primary advantages of cutting flat sheet metal with fiber lasers are its maintenance-free and low-cost benefits. Fiber laser operating costs are considerably lower due to the decreased electrical consumption and the high electrical efficiency of fiber lasers.

Fiber laser beams also provide the faster cutting speeds that today’s applications and customers demand. The higher power density created by the focused beam achieves up to a 5X increase in cutting speeds. These characteristics make fiber lasers the growing choice in cutting technology.

Traditionally, there are three kinds of lasers commonly used in manufacturing: gas, crystal, and fiber. Customary laser cutting offers precision and clean, exact cuts. UV and IR laser systems have made tight tolerances and intricate designs easier to employ in manufacturing processes.

However, some materials are too thick to be processed by standard laser technology. Fiber lasers are able to cut through thick, exotic, metal alloys with laser precision and cleanliness. They extend the benefits of laser cutting to a whole new range of materials. Also, when processing stainless, aluminum, brass, or copper materials, fiber lasers are the fastest and most economical regardless of material thickness.

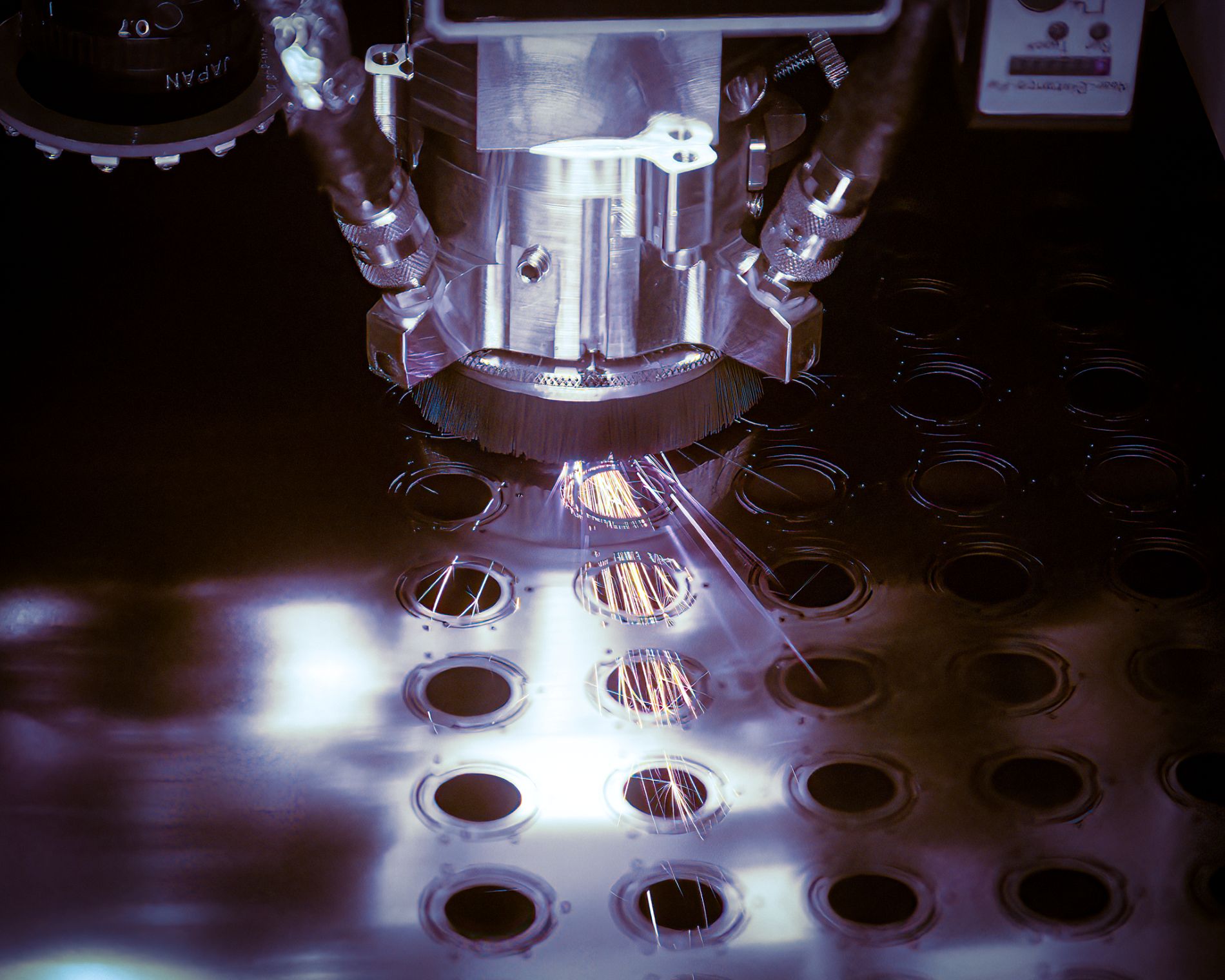

Our fiber laser machine relentlessly cuts through thick metal without compromising the cut geometry or precision. We’ve seen it effortlessly slice through metals that would have been previously impossible to process with other laser technology.

Fiber lasers offer more power, stability, and flexibility to work with the specific materials that are right for your project. They offer all of the following and so much more:

- No warm-up time

- Up to 5X faster cutting speeds

- Up to ½ the cost of traditional cutting

- No beam path maintenance

- Fully sealed fiber optic beam

- Consistent nozzle beam centering

When can fiber lasers be used?

Fiber laser technology can be used across a wide range of industries. It’s particularly well suited to electronics and medical applications. Since it cuts exotic and shiny alloys so well, it’s ideal for cutting pins, electrodes, surgical knives, and antennas.

How are fiber lasers different?

There are three kinds of lasers commonly used in manufacturing: gas, crystal, and fiber. The active medium in a fiber laser is an optical fiber that has been doped with rare-earth elements. Using these elements makes it possible to create extremely high levels of energy without relying on cost-prohibitive pump sources.

As a result, fiber lasers offer more power, more stability, and more flexibility to work with the right materials for your project.

Learn more about how we can help with your next project. We’ll get back to you within 24 hours with a quote and to connect you with our in-house experts.

Specifications

We can help you decide which laser technology is the best choice for your project. Here are some commonly requested specifications for our fiber laser technology:

| Specification | Details |

|---|---|

| Maximum thickness – most metals | Up to 0.08” (2 mm) |

| Maximum thickness – tube | Up to 0.030” (0.75 mm) |

| Maximum thickness – aluminum | Up to 0.04” |

| Kerf size (cut/line width) | 0.0005” – 0.002” (0.010 – 0.050 mm), varies by thickness |

| Minimum hole size (trepanning) | 0.003” (0.075 mm) |

| Minimum hole size (percussion drilling) | 0.001” (0.025 mm) |

| Cutting accuracy | 0.0004” (0.01 mm) |

| Typical tolerances | ±0.001” to ±0.002” (±1 mil to ±2 mil), depending on project |

| Alignment capabilities | Can align to fiducials or components for improved accuracy |

| Laser marking capability | Utilizes Galvo system with 15” x 15” working area |

Conclusion

The time saved when using fiber lasers means higher productivity and greater machine capacity for our customers. If you are running multiple, traditional laser cutting machines, perhaps one fiber machine is the right choice for your operation.

Today’s technology requires us to consider how much faster and more cost-effective fiber lasers may be for cutting operations. The impact of the initial investment can greatly affect the flow of operations before and after parts are cut.

High-power fiber lasers have risen to the top of the fabrication industry in just a few short years. They are easy to operate, produce significantly higher production at lower operating cost, and are more flexible when it comes to working on a variety of materials.

In today’s market, speed in king. A high-powered fiber laser united with automation can make multiple processes and production enormously effective. Fabricators can now rely on fewer cutting machines to produce more than ever.