Medical Device Laser Cutting Lives Depend on Your Devices

Laser Cut Components for Medical Devices

The medical industry presents unique challenges to precision parts manufacturers. Not only are the applications cutting edge, but demanding in terms of traceability, cleanliness, and repeatability. A-Laser has the equipment, experience, and systems in place to provide our customers with the highest quality products in the most reliable and efficient manner possible.

A-Laser brings unique expertise into medical device industry. We use advanced laser technologies to provide maximum precision on parts for all types of medical devices. This precision is crucial to medical and surgical parts manufacturing.

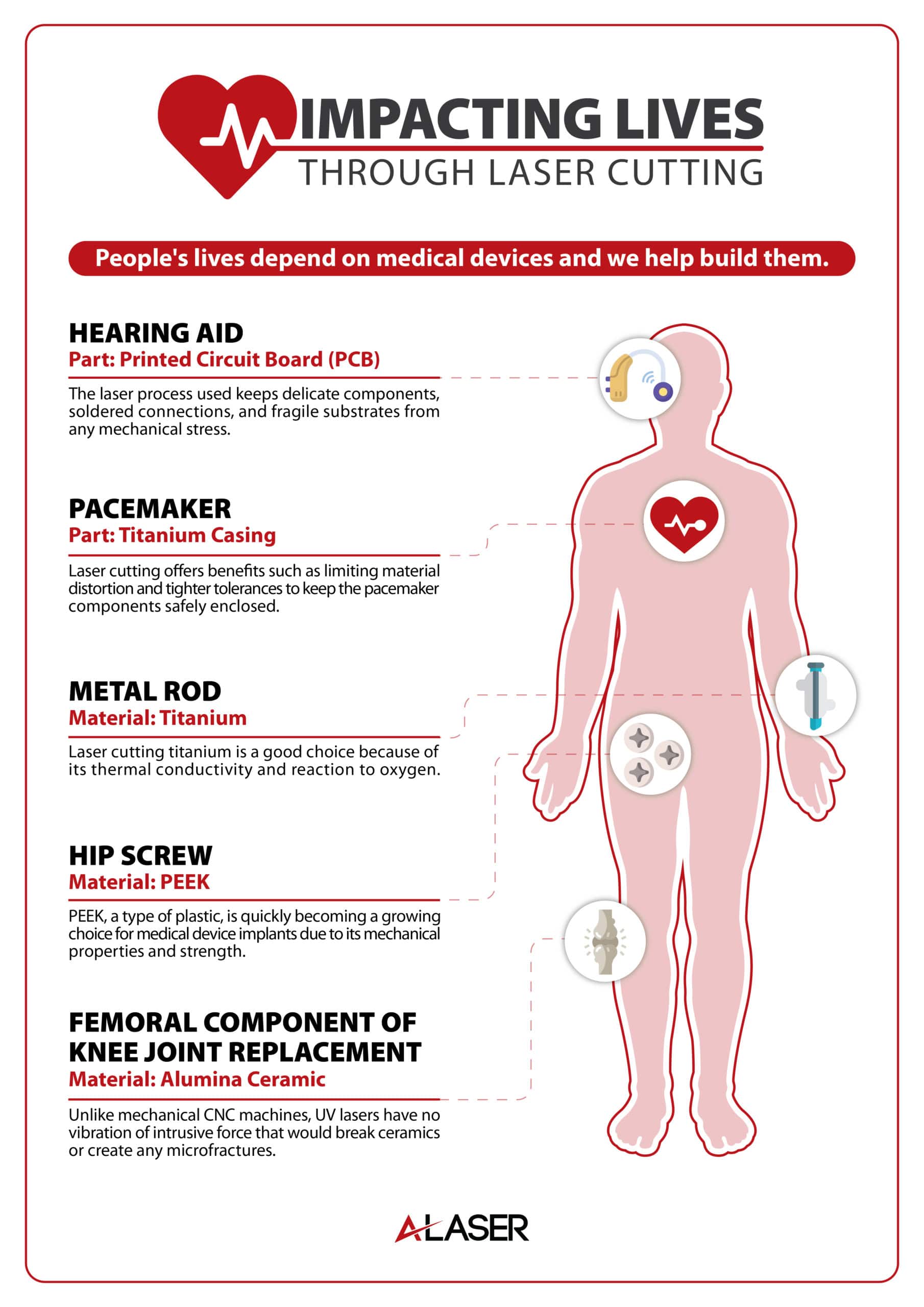

We know that people’s lives depend on your equipment. And we’ll help you build the most reliable devices possible.

More Than A Job Shop

A-Laser offers comprehensive engineering reviews to ensure that we can cut your products quickly and reliably.

If you’re struggling to get a part to meet your need, let us help. We’re happy to sit down with you and do thorough contract and engineering reviews so you know exactly what a job will cost. We’ll work with you to design an engineer strategy to ensure maximum reliability under the most extreme tolerances.

What We Offer

A-Laser offers precision laser machining, laser cutting, laser drilling, ablation, skiving, and depaneling of metals, plastics, and other materials. We can cut nearly every medically-approved material to provide you the best solutions for medical device manufacturing needs.

We use the most precise lasers and latest cutting technologies in the industry. At A-Laser we constantly improve our output and tolerances. Our team also keeps current with changes in the laser technology field and remain in full compliance with the latest industry codes and mandates.

Our focus is on constant precision in manufacturing laser parts, providing top quality and reasonable prices – so you can build the best, most reliable devices possible.

The expertise of our team extends on knowledge of Process Validations including FAI. Our services provide complete solutions for your laser needs.

Why A-Laser?

Major Fields of Application

A-Laser provides advanced technologies, high precision cutting, and extensive materials expertise. We offer laser cut components for surgical devices.

Additionally, we fabricate parts that will help process genetic information easily and universally. Our team cuts laser components for endometrial ablation systems. We provide this precision on industry standard materials including a variety of Ti alloys.

Medical field of orthopedic devices changes rapidly. A-Laser provides innovative solutions to the constantly changing orthopedic market. Materials used for orthopedic parts are particularly important in providing optimal medical help to the patient. Biomaterials such as Ti and Ti alloys, provide proper resistance, strength, and durability of orthopedic components.

A-Laser can process laser cutting for implantable and traditional medical device components to meet your needs. We provide quick turns, ultra-high precision, and an engineering partner you can trust.

Our team will work closely with you to find the best solutions for your components from prototyping to production.

Our Support

Our operations and engineering staff combine decades of experience to provide our customers with ideal solutions for their prototyping and production needs. Often our customers do not know the full range of our capabilities. We are available to assist with any design questions you have, from heat affected areas to hole pitch to cut paths. When it is time to move to production we can assist in material selection and layout to make the process as cost effective as possible.

Service & Quality

Our technical support, combined with the newest technology and quick delivery has set A-Laser apart as an industry leader.

Fine pitch and high density patterns increase in demand every day and the need to meet and verify these tolerances has become a necessity of our customers. We’ve solved this issue, not only with the best laser cutting equipment, but also advanced scanning equipment. Positional accuracy, thickness and pattern verification are all tracked.

A-Laser is committed to total quality and is fully certified ISO 9001:2015.