Laser Cutting Cost Estimator

How Costs are Calculated

Laser cutting costs are calculated by the time a job takes on the laser. The time the job takes on a laser is dependent on the type of materials and the thickness of the materials being cut.

*Please note: these are only estimations and do not include material, labor costs, or setup fees. Contact us if you’d like a full quote.

Laser Cutting is Changing Manufacturing

Our laser cutting cost calculator gives you a quick estimate of the cost of laser cutting for your specific project.

We’ve made it easy to figure out the approximate cost of laser cutting steel, Kapton/Cirlex, and other materials based on the parameters of your project. Of course, every project is different, and we’re happy to offer you a full quote. But this is a fast, easy way to get a ballpark idea of laser cutting costs for your project.

Why is it worth investigating the costs of laser cutting?

Laser cutting is a high-accuracy process that avoids many of the drawbacks of traditional manufacturing methods. It involves high-energy laser beams focused on extremely small surfaces; the energy density causes the material to melt and evaporate, leaving behind a very precise cut. It’s a time- and cost-effective method that delivers unparalleled control, all with minimal stress to the materials.

Laser cutting is often preferred to traditional methods because the heat affected zone, or HAZ, is so small. Laser cutting also yields precise, smooth cuts, giving engineers greater freedom to design intricate parts and pieces. Learn more about our UV laser ablation and IR laser cutting services.

How A-Laser estimates laser cutting prices

Technology is changing fast, and our clients often are under tight time constraints. That’s why it’s helpful to be able to quickly estimate the cost of laser cutting for a specific product. We developed our laser cutting cost calculator to help you make informed decisions about your options for any given project. If you have never used laser cutting in your process before, you may be surprised at the price, especially given the superiority of the results.

In order to accurately estimate the cost of cutting steel, Kapton/Cirlex, PEEK, beryllium copper, and FR4, we need to know the basic parameters of your project. That includes material thickness, distance of the laser cuts, and the total quantity needed.

Our calculator then applies that data to a cost calculation that takes into account all the costs of laser operation, including machine operators, equipment and maintenance costs, facility expenses, and more. It’s also based on historical data from our years of experience in the laser cutting industry.

While requesting a quote is the most accurate way to get a cost estimate for working with A-Laser, our cost calculator is a good way to get a general idea of how the cost of laser cutting compares to other methods.

How to Calculate Cost-Cutting in Laser Cutting Services

Understanding the Basics of Laser Cutting Costs

Laser cutting costs are primarily determined by the time a job takes on the laser. This time is influenced by two main factors: the type of materials being cut and their thickness. Different materials have varying levels of difficulty to cut, affecting how long the laser needs to work. Thicker materials generally take more time to cut through than thinner ones, further influencing the cost.

Key Factors in Cost Calculation

- Material Type and Thickness:

- Different materials, such as steel, Kapton/Cirlex, PEEK, beryllium copper, and FR4, each have unique cutting requirements.

- Thicker materials typically require more time and energy to cut, which increases the cost.

- Distance of Laser Cuts:

- The total length of the cuts required for a project impacts the laser operation time.

- More extensive cuts mean more laser time and, therefore, higher costs.

- Quantity Needed:

- The number of units that need to be cut affects the overall cost.

- Larger quantities might benefit from economies of scale, reducing the per-unit cost.

How to Calculate Laser Cutting Time

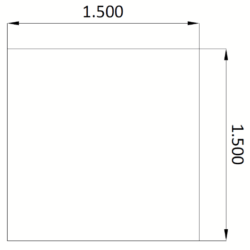

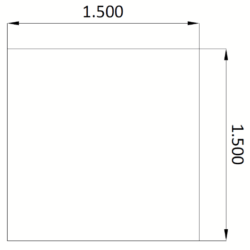

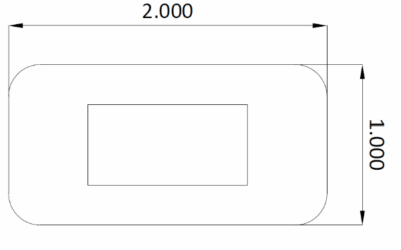

Laser cutting time for example can be as quick as a few seconds or perhaps take an hour or several perhaps depending on the project’s size and requirements. A part cut from 3mil thick polyimide, with simple geometry could cut in about 12 seconds at 5 parts per minute at 300 parts per hour. On the other hand, a part with the same geometry made from 20mil titanium will take 30 seconds at 2 parts per minute and 120 parts per hour. If each has an order of 1000 quantities, the laser cutting time amounts is very different. Example of this:

The cutting time changes due to the differences in each project’s requirements. The thinner polyimide ablates rapidly and moves at a high rate. The thicker material, though the same geometry, takes more energy and requires a slower cutting rate. Additionally, the number of laser passes or cycles will be higher than the polyimide material. Since laser cutting time and cost affect each other, knowing how this time is calculated can help you anticipate laser cutting cost calculation. Several elements determine the laser cutting time, including the complexity of the design, the material thickness, and the speed and power of the laser cutter. The following factors are used in determining the cost of laser cutting and the production time required to manufacture.

- Material Type and Thickness: Material choice and the required thickness will determine the best laser technology used. Different systems can cut the same material but will vary in cutting speed. Is the material reflective or fragile? Laser cutting speeds are adjusted accordingly for quality cut. Some laser systems cut by a series of laser passes. This is the number of times the laser runs each cycle. Harder to cut materials will require more laser passes and affect the production time.

- Laser Technology: Different materials will require different laser systems like Ultraviolet, Infrared or Fiber for example. Each has levels of power and capabilities that services providers determine which is best for time and cost.

- Linear Distance: The programmed path of the laser is measured as linear distance. This is a combination of all cut features. Designs will affect the production time and laser cutting costs per hour.

- Tolerance and Inspection: Inspection of parts is always part of the manufacturing process. However, if additional levels are required such as AQL or 100% inspection, this additional time will be factored into the total lead time.

- Quantities: A handful of R&D precision parts will indeed cut faster than a production run. Keep in mind that for mid to high level volumes, laser manufacturers will nest parts to increase efficiency per sheet and reduce set up time. This in the end results in the quantity of laser cutting costs per hour.

Additional factors also influence the overall production throughput:

- Handling of material Pre and Post laser: Materials can be extremely delicate and prone to damage if not handled properly. Laser operators will take additional care to keep the surface free from scratches and marring.

- Packaging: If the packaging requires third party systems to be used like custom trays, gel-paks, custom plastic boxes and so on. Additional time and labor will be needed.

- Finishing: Post laser processes will add the lead time. Finishing methods like sanding, passivation, tumbling, anodizing and powder coating are some of the post processing that may be required and extend the final production window.

Laser cutting time is a calculation of all the variables mentioned and includes the material type, quantity of parts, the linear distance of each part, to name a few. From years of gained knowledge, qualified laser service providers will review the variables and formulate the expected lead time. Laser cutting cost calculation and processing time is based on years of experience. These calculations are the foundation that production schedules are formed and executed to meet customer’s demands and expectations.

How do you calculate laser cutting cost?

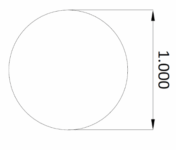

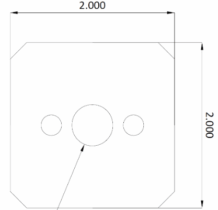

Material thickness and geometry are just a couple of factors affecting laser cutting costs. Project cost is important to know so let’s review an example on how the factors involved are used in determining the cost of laser cutting. For example, the images shown below of three different geometries made from stainless steel:

Understanding your project’s goals will help the manufacturer plan and optimize the laser production process. Laser service providers calculate the laser cutting cost by using a data source accrued from years of business and experience. Understanding the factors that influence the per unit and hourly rate enables the laser manufacturer to estimate the cost of your project. Precision laser cutting services calculate the cost by the factors listed below:

- Review of data and scope of work: Review of the CAD file or computer aided design file is foremost in the process. This will inform the precision laser cutting service provider of the material, the grain direction to be used (if needed) the geometry, the tolerance, any post processing requirements.

- Material costs: Is the material common like 304 SS or is the material thin strips of molybdenum, for example. Materials already in stock will offer shorter lead times as opposed to materials that are custom ordered and may have lead times of multiple weeks or months from delivery.

- Material Thickness: Many laser cutting projects use materials like Kapton, molybdenum, titanium, tungsten, silicon rubber and more. Materials such as these come in numerous thicknesses. What may cut at 100mm per second at 0.005” Mils thick. May cut at 20mm per second at 0.012″ Mils thick. The cost of laser cutting will be affected by the material thickness.

- Linear Distance: A key factor in determining laser cut costs is the linear distance. A 100 mm distance will be cut faster than 400mm distance, assuming the design, material, and thickness remain the same. Does the design need custom nesting or tabbing? Manufacturers are great at maximizing material usage and will nest parts together in order save material and minimize the laser cutting costs per hour. Sometimes the parts need to be tabbed to prevent damage during the cutting process.

- Laser System Used: How fast in millimeters per second will the laser run is determined by the system used to reduce the cut time. This adjustment is part of what is called, the “laser tool”. This tool is adjusted to find a balance of efficiency and quality.

- The tolerance and inspection level required: Laser cutting cost calculation considers the inspection levels required. Precision laser cutting services, like other manufactures, have a standard inspection level. This ensures the manufactured parts meet the requirements. However, some projects and industries require a higher level of conformance and additional inspection is needed like AQL levels or 100% inspection. The cost for additional quality inspection and certificates is considered for the overall processing.

- The handling Pre and Post: Materials can be very costly and fragile in their nature. For example, extremely thin foils and brazing alloys may need extra care and handling. Their end use may reject any surface scratches or blemishes. The time and processes needed to ensure proper care is another factor.

- Special Packaging: Another factor affecting laser cutting costs is the packaging requirements. All manufacturers have procedures in place to ensure the time and effort to produce a precision part is not lost through inadequate packaging. Cost is added for projects where specific requirements are needed such as custom trays, custom foam and boxes, specific packaging quantities and at times special shipping methods.

- Additional Finishing: Not all precision laser cut parts require a post finishing process, but those projects that do will have the cost of sanding, tumbling, passivation, anodizing, powder coating, and others added to the final cost.

The cost of laser cutting a project can vary depending on several factors. While some shops offer a flat fee per project, others may determine laser cutting cost by combination of factors of material used, the linear distance, the level of tolerance and inspection and others for the laser cutting cost calculation. Additionally experienced laser service providers will have data sources from past jobs that they can pull information from. This gained knowledge enables accurate quotations to be formed and structured production planning to be done. The overall effect is an efficient manufacturing process and customer satisfaction in receiving a high-quality laser cut component.

How is Laser Engraving Price Calculated?

When a customer comes in the shop wanting to know the cost of laser engraving their precision part, we will tell them the cost depends on a few key factors. The recipe involves first the material. For laser engraving of stainless steel for example it will take different settings and more time than engraving on FR4, printed circuit board material. As in most manufacturing, time plays an important role in the cost calculation. “What about the designs” our prospective customer may ask? We will advise for complex and intricate geometries the time needed to ablate, will take longer than a simpler form. “Can it be any size? Well of course within the capability of the laser bed, but generally, a larger size will take longer thus increasing the cost than a smaller area. “How can I see a discount?”, the customer may ask. For larger quantities discounts are often applied as bulk quantity orders keep the laser machines running, which is a cost savings for manufacturing. We will advise the customer that additional services like polishing, painting, plating will be an additional cost. As our now informed customer has a good idea of the factors of how laser engraving costs are calculated, we would like to remind them of these key points:

- Material Choice: Laser engraving on harder materials like titanium, tungsten, and steel will take more energy and time than engraving on softer metals and materials like copper, plastic, and aluminum.

- Design Complexity: A simple form like a square or circle, will take less time to process than a more complex design or multiple lines of nomenclature.

- Size of the engraving: Smaller is quicker in most cases. The area to be engraved is determined by the parent part to receive the engraving. This too is limited to the laser’s capabilities in the bed size and how much travel can be programed.

- Cost Adjustments: Service providers may have an hourly shop rate to which smaller orders will fall into. This can be much higher when broken down as a per unit cost. For example, a shop rate of $300 per hour with an order or two will be $150 each. The same shop rate but with 60 parts processed within the hour would be $5.00 each.

For calculating laser engraving cost, a key point to keep in mind is communication. We receive daily inquiries on services and questions about what the cost will be. Laser service providers have the experience and knowledge to conduct a prompt review of the project and offer a quotation. The need for a precision laser engraved part can be a crucial element to an assembly. This process is important to a supply stream and allows for potential replacement by using the engraved part number as confirmation. By working with customers, is part of the manufacturing process to ensure your part is laser engraved to the high quality required and demanded.

Why choose A-Laser today?

Are you concerned that the materials you need to have laser cut can’t be done with excellence and precision? When you chose A-Laser, you won’t need to be. We have you covered when it comes to laser cutting services. A-Laser has the latest technology, and we’re ready to help you build the future.

A-Laser cutting technology has taken the precision parts industry to new levels, enabling increased complexity in design, higher cut quality, and the ability to maintain tighter tolerances through laser ablation. In addition to perfecting the use of IR and Fiber laser technologies, we went to the next level and mastered UV laser technology. With our state of the art LPKF UV laser machines, A-Laser can offer the full spectrum of laser cutting services.

Still not sure we can handle whatever you give us? You can check a list of all the materials we service here. We’re always willing to go the extra mile to bring you the latest in micromachining technologies so you’ll have no concerns about material choices for your next project or design. With A-Laser’s expertise and capabilities, your imagination is truly the limit!