Acid Cleaning

Industrial Parts Finishing Services

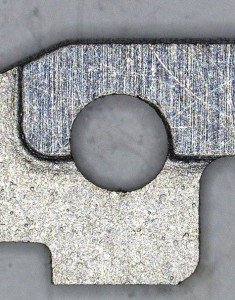

In the manufacturing realm, ensuring the pristine quality of industrial parts is paramount. Acid cleaning, a type of chemical cleaning, is a widely utilized method in the manufacturing industry for removing impurities and contaminants from metal surfaces.

What are the benefits and risks of acid cleaning?

There are many benefits of acid cleaning. It offers unparalleled efficacy in removing tough residues, oils, rust, and scale from metal surfaces, ensuring optimal performance and longevity of industrial parts. Moreover, acid cleaning facilitates enhanced adhesion for subsequent processes such as coating or bonding.

However, it’s essential to acknowledge the inherent risks associated with acid cleaning. Improper handling or misuse of acidic solutions can lead to corrosion or damage to the metal substrate. Therefore, it’s imperative to entrust this task to experienced professionals who understand the nuances of chemical cleaning processes. Proper execution of acid cleaning requires an understanding of chemical reactions and their effects on different metal substrates. Without this expertise, there’s a significant risk of damage to the metal surface due to corrosion or etching caused by the acidic solution. Additionally, incorrect dilution or application methods can exacerbate these risks, leading to compromised structural integrity or surface finish of the material. Therefore, entrusting acid cleaning to experienced professionals ensures not only effective cleaning but also safeguards against potential damage, preserving the integrity and functionality of industrial parts or equipment.

What types of acids are used in acid cleaning?

Several types of acids find application in acid cleaning processes, each tailored to specific metal substrates and contaminants. Commonly used acids include hydrochloric acid, sulfuric acid, phosphoric acid, and citric acid. The selection of the appropriate acid depends on factors such as the type of metal being cleaned, the nature of the contaminants, and environmental considerations.

What metals are suitable for acid cleaning?

A wide range of metals can undergo acid cleaning with good results. Metals that are good candidates for acid cleaning often have a high reactivity with acids, allowing for effective removal of contaminants. Common examples include:

- Iron and Steel: These metals react readily with acids like hydrochloric acid (HCl) to remove rust, scale, and other impurities.

- Aluminum: While aluminum is generally resistant to corrosion, it can be cleaned with specific acids like phosphoric acid (H3PO4) to remove oxides and prepare surfaces for further treatments like anodizing.

- Copper and Brass: These metals can be cleaned with nitric acid (HNO3) to remove tarnish and restore their luster.

- Zinc: Zinc can be cleaned with hydrochloric acid to remove oxides and prepare surfaces for plating or other finishes.

- Stainless Steel: While stainless steel is generally resistant to corrosion, it can be damaged by aggressive acids, especially in the presence of high concentrations or elevated temperatures. Care must be taken to adjust the formulation when acid cleaning stainless steel.

Metals that are not suitable for acid cleaning often have low reactivity with acids or may undergo undesirable reactions.

- Gold and Silver: These precious metals are relatively unreactive and may not be significantly affected by acid cleaning.

- Lead: Lead can react with acids to form toxic compounds, making it unsuitable for acid cleaning.

- Magnesium: Magnesium reacts vigorously with acids, potentially leading to dangerous reactions or hydrogen gas evolution.

The versatility of acid cleaning makes it a preferred choice across diverse industries, including aerospace, automotive, electronics, and medical device manufacturing.

At A-Laser, while we specialize in precision laser processing, we understand the importance of offering comprehensive solutions to our clients. Through trusted partnerships with reputable vendors specializing in chemical cleaning services, we ensure that our customers receive the highest quality standards throughout their manufacturing journey.