Infrared (IR) Laser Cutting

As the technological world grows bigger and more competitive, so does the need for smaller products. The manufacturing of parts for goods such as mobile devices, computers, and gaming equipment is at an all-time high. The components in these machines are decreasing in size and increasing complexity as demand for them goes up. This calls for the ability to provide manufacturing with the utmost precision, and infrared (IR) laser cutting is an excellent solution.

Why Choose IR Laser Cutting?

Our infrared (IR) lasers operate with the highest advanced technologies and produce a clean cut on ultra-thin metal, the most popular material the application is used for.

We utilize IR lasers and metal cutting services that are ideal for companies in need of the utmost quality, tight tolerances, and have intricate requirements.

The lasers operate at a 1064 nanometer wavelength and have one of the most stable motion systems in the world for metal laser cutting. The beam diameter used to create these thin metal parts is so small that the most sophisticated designs are possible with our metal IR laser cutting.

IR lasers are ideal for:

-

Contact-free processing – no mechanical stress or distortion

-

Material thicknesses between 0.001″ and 0.025″

-

Fine feature cutting with a sub-40 micron beam diameter

-

Consistent tolerance repeatability to ±0.5 mil

Laser cutting services are widely varied in the applications that best suit them and our niche is thin, high quality parts for industries that can’t compromise on accuracy.

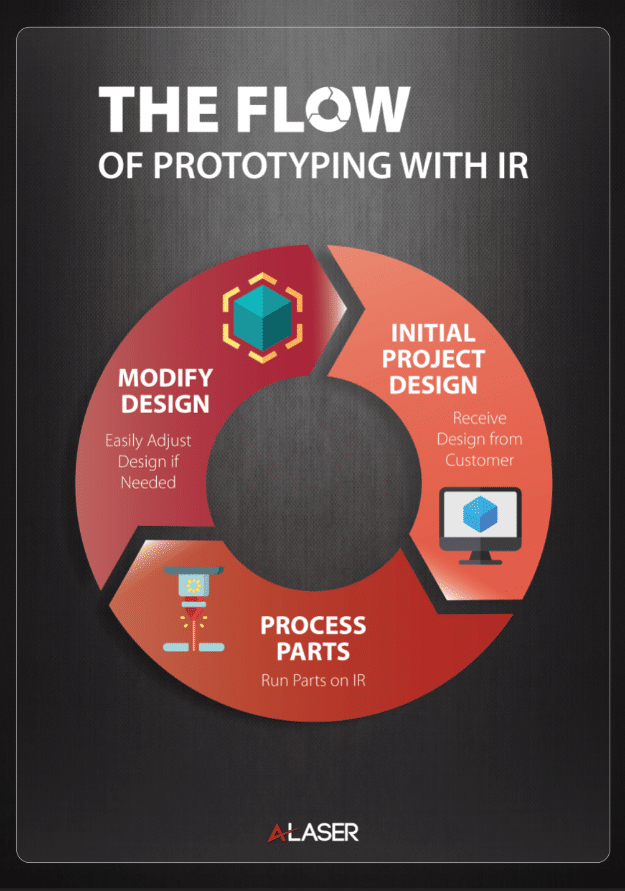

In addition to utilizing state of the art equipment, A-Laser knows that our success, and that of our customers, is dependent on our ability to provide high-quality laser cut parts in the quickest time frame possible. We are typically able to deliver low volume runs within 24 hours and higher volumes within a few days.

Interested in learning more about our IR laser capabilities or other laser cutting services? We’d be happy to chat.

IR Lasers

IR lasers are commonly used in metal cutting and welding applications. Their ability to penetrate and interact with metal surfaces makes them effective for tasks such as cutting, welding, and heat treating in industries like automotive manufacturing and metal fabrication. IR laser cut services are a great solution for metals, including stainless steel, nickel, Datum Alloy, and more. IR, or infrared, lasers carve their niche in the infrared spectrum, known for their versatility and widespread applications. Key benefits of IR lasers are:

- Penetrative Power for Materials up to .025”: IR lasers exhibit impressive penetrative capabilities, making them suitable for handling materials up to .025” with ease.

- Useful for Metal Materials: Machining metal parts, specifically infrared laser cutting is the process in which a beam of invisible IR radiation essentially creates a controlled burn at microscopic levels. This burn liberates a small portion of material from the workpiece.

What is laser precision parts manufacturing?

Machining metal parts, specifically infrared laser cutting is the process in which a beam of invisible IR radiation essentially creates a controlled burn at microscopic levels. This burn liberates a small portion of material from the workpiece. This is often described as a “thermal separation method.” In this process, the laser light will be concentrated through optics to increase its utility. The more concentrated the beam can be the more efficient the separation method will be but more on this later. In order to aid the laser cutting process often an “assist gas” will be used. This is a pressurized gas that will help penetrate the material, increasing the burn rate, and removing waste material. Common gasses are compressed air for regular cutting, pure oxygen for higher burn temperatures, nitrogen for clean cuts with reduced oxidation plus many others for specialized properties. This gas can have the added benefit of cooling the workpiece just as the coolant in a traditional CNC would.

Types of IR Lasers

| IR Laser Type | Wavelength | Best For | Pros | Cons |

|---|---|---|---|---|

| Fiber Laser (Nd:YAG) | 1064 nm | Metals (e.g., stainless, nickel, titanium) | High power density, excellent focusability, low maintenance | Higher upfront cost |

| CO₂ Laser | 10,640 nm | Organics, polymers, wood, cardboard | Lower cost, good for non-metals | Poor absorption in reflective metals, more maintenance |

These two lasers differ not only in wavelength but also in maintenance costs, power, bandwidth, reliability, and more.

Fiber lasers (Nd:YAG) will output a beam close to 1,060nm in wavelength. CO2 will output 10,640nm. Why would someone choose one over the other? Mainly this comes down to the material that will be processed. It can generally be broken down into metals being suited to the lower wavelength and natural materials, such as wood or cardboard, being suited to the higher wavelength.