Solution In Precision Manufacturing

Metal laser cutting services are a unique aspect to laser service providers. When you are ready to transform your ideas into tangible metal masterpieces, state-of-the-art metal laser cutting services can be a great solution. Offering unparalleled precision and flexibility, empowering you to bring your most intricate and often critical designs to life. With multiple choices available to manufacture a metal precision part, how does metal laser cutting differentiate itself from the rest? It’s not an easy choice since all methods of manufacturing do have their attributes where they excel and areas where the technology is challenged. A common story with laser technology is that the initial work was done by some other method, but it was discovered later that the initial chosen technology could not provide the needed geometry or handle a particular grade and thickness of the metal alloy. One intriguing example was in support of life sciences and the study of wasps and how best to control them.

A very complex system was developed by a customer to review certain traits on wasps and separate them into two groups based on the criteria of the study. The designed mechanisms were small and complex and would need to be made from stainless steel alloys. This strength was part of the structural integrity, but did not add much weight. It had to function with multiple moving parts that basically divided the subjects into different chambers by a series of shutters. Methods such as stamping and CNC machining were tried, but the size and thinness of the stainless steel proved that another technology was needed. Metal laser cutting was the solution. With the capability to hold the tight tolerance of the geometry and not damage the thin gauges of the metal components, the project was successful and moved from R&D and proof of concept to volume manufacturing.

What Services Are Available?

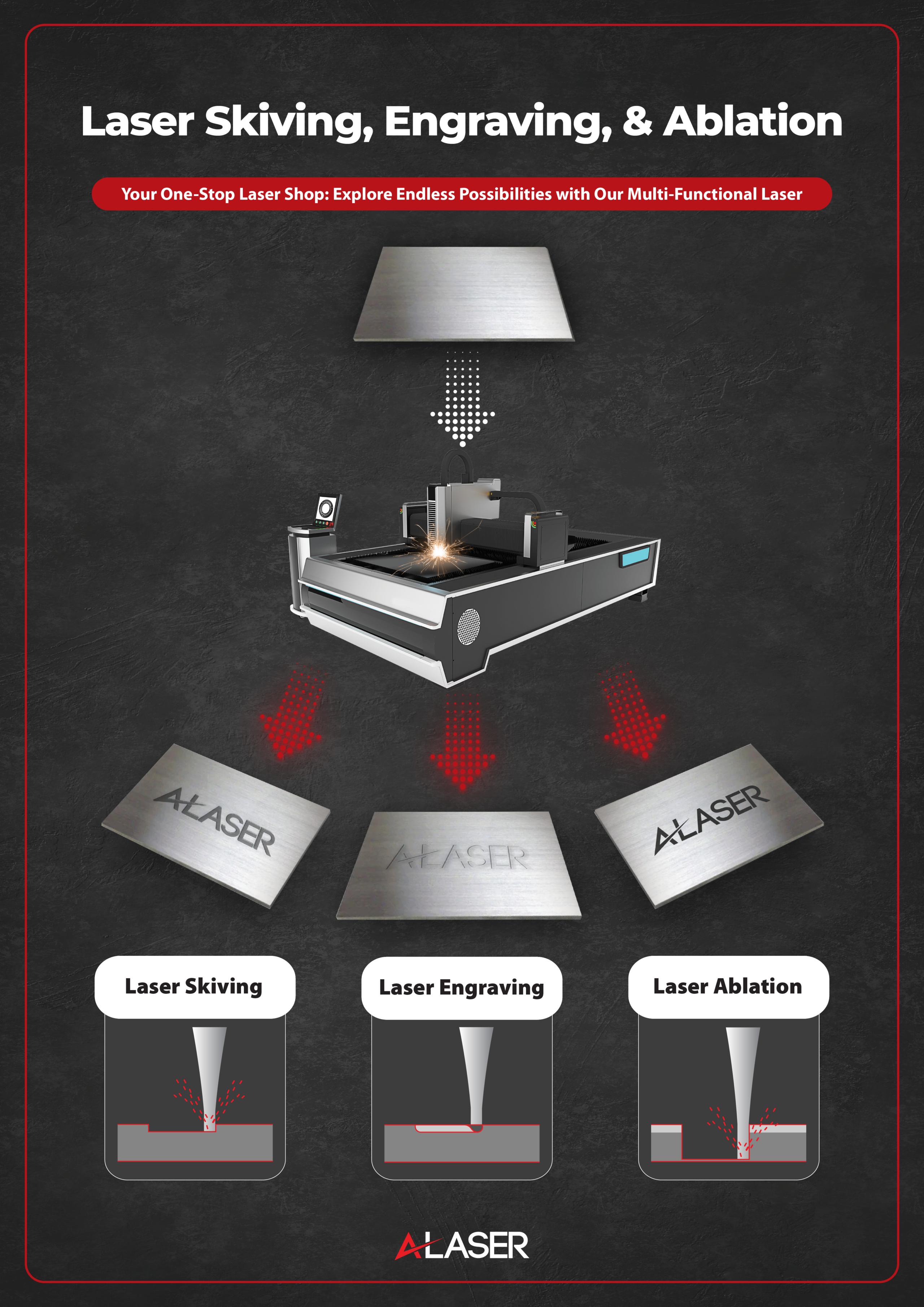

Metal laser cutting services offer a range of precise techniques to manipulate metal materials.

- Laser etching uses a focused laser beam to remove a thin layer of material, creating permanent markings or designs on the surface. This process is ideal for adding logos, serial numbers, or intricate patterns to metal components.

- Laser skiving selectively removes material from a surface without affecting the underlying layers, enabling precise cutting, cleaning, or exposing hidden features.

- Laser ablation involves vaporizing material with a high-powered laser beam, creating precise cuts or removing unwanted material. This technique is commonly used for cutting through materials to produce intricate shapes, drilling holes, slots and other features. By combining these techniques, metal laser cutting provides a versatile solution for a wide range of applications, from industrial manufacturing to artistic creations.

Processing these capabilities involves the adjustment of laser parameters or the “laser tool”. Fine calculated refinement of the laser power, speed, focus, frequency, dwell time, and other factors are used for each type of laser process. Materials do affect these parameters resulting in custom laser processing for each job.

The above are the basic categories that can be offered under metal laser cutting, but it does go further into depth by focusing on materials for additional capabilities like:

- Laser Cutting Sheet Metal: Thickness ranging often from 0.500 to 6mm in thickness

- Laser Cutting Brazing Alloys: Challenging to handle using other methods, these types of alloys are a great fit when cut by laser technology.

- Laser Cutting Foils: Generally, from 0.0127mm to 0.254mm thick.

- Laser Cutting Tubes: Some metal laser cutting systems cut only straight through, while others have rotational capability along the tubes axis.

Metal alloys are used across many industries from shims to complex medical implants, cathode manufacturing and oil and gas applications. Some of the more frequently requested are stainless steel, aluminum, copper, nickel, tungsten, titanium and brass.

Are Metal Laser Services the Best?

The tools today are far beyond what was accessible to manufacturers 40-50 years ago. Times change and so does the type of materials we have for use in aerospace, optics, energy, medical and textile industries to name just a few. The methods that manufacturers use also have changed by upgrades to the machines and capabilities from advanced electronics that in turn develop better sensors, controllers, thermal controls, motors, pumps, and so many more system components. In short, every manufacturing method is better today but nothing can do it all. This is how laser cut metal services can add value and best fit within the capabilities it has. There are projects that require the precision of metal laser technology like brackets and shims used in aerospace, optics and battery energy for example. There are also projects where laser cutting services are needed to complete the manufactured part. Laser etching can add the needed part information on the surface or laser skiving can remove a surface layer to expose the desired underlying coating. Laser ablation may be asked to cut small features into thinner areas of a machined part, where other tooling is too large. It’s not what is the best, but what technology can make the difference in manufacturing of your project.

Precision Engineering, Elevated

Metal laser cutting, with its capabilities in laser ablation, skiving, and etching, is revolutionizing the manufacturing industry. This technology seamlessly integrates with traditional manufacturing methods, offering unparalleled precision and efficiency. By partnering with laser technology specialists, engineers in multiple disciplines can unlock new possibilities, to create the ideas off the computer to real precision components. By doing so, manufacturing can reduce production time and minimize material waste. Whether you need intricate components, custom designs, or surface treatments, our laser cutting services are here to elevate your project to new heights.