Fiber Laser Cut

At A-Laser, we bring cutting-edge precision and adaptability to your projects with our advanced fiber laser cutting services. Our state-of-the-art fiber laser cuts complex design requirements with a high degree of accuracy, making it the ideal solution for industries ranging from aerospace to electronics.

What is Fiber Laser Cutting?

Fiber laser cutting utilizes highly focused laser beams for unparalleled precision in cutting various materials. This process results in optimally sharp edges, minimal heat-affected zones, and superior surface quality. Fiber lasers are known for their efficiency and cost-effectiveness, especially for intricate and detailed work.

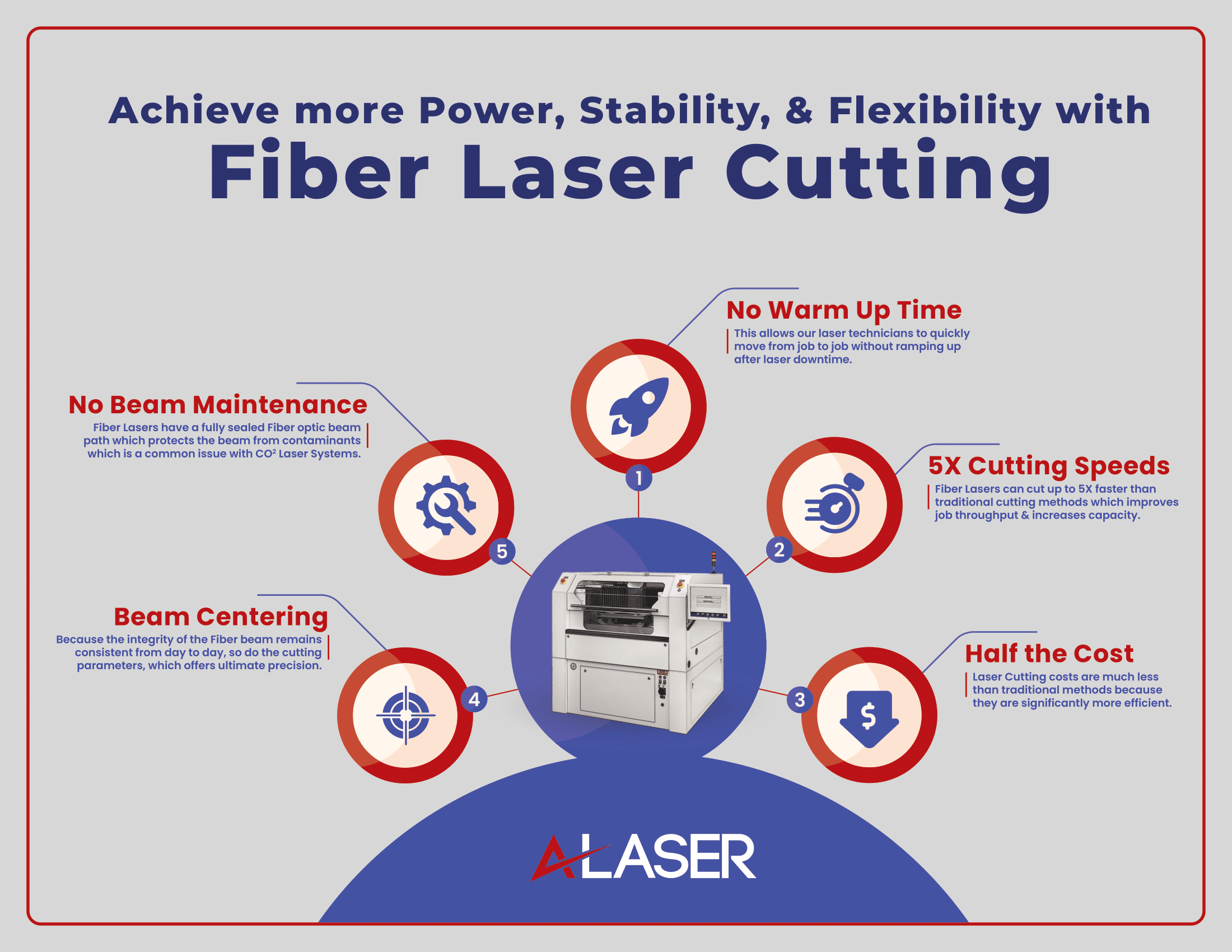

Fiber Laser Cut Advantages

When Should You Choose Fiber Laser Cutting?

Fiber laser cutting is ideal when precision, clean edges, and speed are essential. It’s especially suitable for projects requiring intricate patterns or tight tolerances. This process excels in small and medium-sized production batches and can adapt to quick design changes efficiently.

Applications Include:

- Precision electronic and mechanical components

- Custom parts for aerospace and automotive industries

- Medical device manufacturing

- Decorative metal elements and intricate gears

| Industry | Applications |

|---|---|

| Aerospace | Precision parts, engine components |

| Automotive | Body parts, engine components |

| Electronics | Circuit boards, electronic components |

| Medical | Surgical instruments, implants |

| Jewelry | Intricate designs, custom pieces |

Fiber Laser Cutting Innovations and Advantages

The fiber laser system we use stands apart with its ability to handle not only traditional metals but also ceramics—a capability not widely offered on many other fiber laser cutters. This flexibility ensures that clients with specialized materials have reliable solutions available. Our machine’s innovation lies in its optimized performance, combining power, precision, and adaptability for a variety of applications.