Laser Engraver

Looking for precision and creativity in laser engraving? Our laser engraver services deliver exceptional results tailored to your unique needs. From intricate designs to functional markings, we help you achieve controlled depth and lasting impressions or functionality.

Common Uses for Laser Engravers

Laser Engraver vs Other Laser Processes

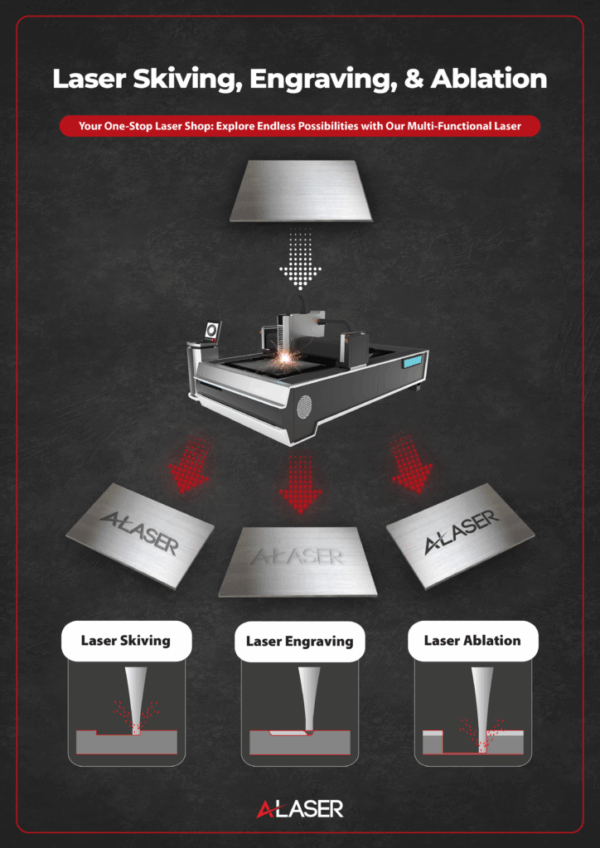

| Feature | Laser Engraving | Laser Skiving | Laser Ablation |

|---|---|---|---|

| Depth | Shallow, precise cuts for designs and markings | Deeper material removal, exposing specific layers | Cuts entirely through material |

| Primary Use | Custom designs, functional markings | Layered material separation, electronics | Full cuts, material removal |

| Material Compatibility | Metals, plastics, ceramics | Flexible circuits, films, composites | Metals, ceramics, polymers |

| Finish | Smooth and clean | Clean, layered appearance | Fully penetrated cut |

| Applications | Decorative, identification, branding | PCB manufacturing, microelectronics | Precision cuts, medical components |

Choose the Right Laser Service for Your Project

Not sure if laser engraving is the right fit for your application? Here’s a quick guide:

USE LASER ENGRAVER:

for shallow, intricate designs and surface markings.

CHOOSE LASER SKIVING:

for applications requiring deeper cuts or layered material separation.

OPT FOR LASER ABLATION:

when complete material removal or cutting is needed.

Why Laser Engraving Stands Out

A laser engraver offers unparalleled precision for permanent, detailed markings that stand the test of time. Compared to mechanical engraving, the laser process is non-contact, eliminating wear and tear on tools and minimizing the risk of material damage. This makes it ideal for industries where accuracy and durability are paramount.

When it comes to laser engraving, having access to a professional laser engraver service ensures your project is executed with precision and reliability. Whether you’re designing custom components or creating intricate art, understanding how laser engraving fits into the broader spectrum of laser technology empowers you to make the best choice for your needs.