Learn and Leverage New Skills

One of my passions is finding creative methods to solve daily problems. These could be small little niggles that happen often or large hurdles that impact my work. Developing the skill of problem-solving is as important as solving a problem itself.

Having the task of adding our company logo to a custom part I was designing, I needed to get my data right first.

One of the issues facing designers is low-quality data being sent. My weapon of choice for mechanical design is Autodesk Fusion 360 which offers the option to import SVG (Scale-able Vector Graphics) files. The only image files I had locally were .PNG files. No matter the quality we are still a slave to the pixel.

Enter Inkscape

My first choice for new ideas is to play with FOSS products. Learning new software packages, again and again, prevents one from being “boxed in” to their current setup.

After searching online for vector graphic editors (of which there are hundreds!) I landed on Inkscape. This is graphical design software often presented as the best alternative to Adobe Illustrator.

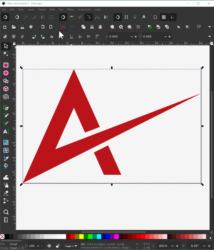

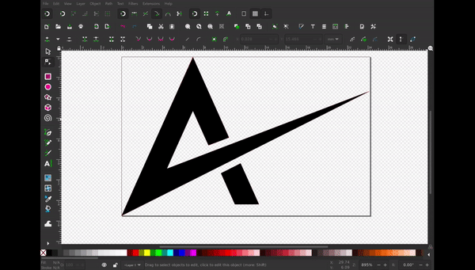

I’m no graphic designer but I have enough curiosity to get through any problem. Our A-Laser logo is sharp and only consists of a single colour. This is a perfect starting point.

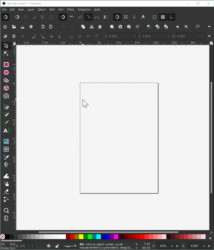

Loading the Image

We won’t go through the setup of Inkscape. Many a YouTuber are a better resource than me for that.

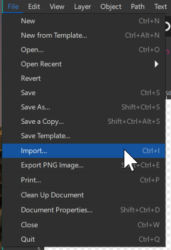

Load the image through the file menu or press Ctrl + I

Select the image you need. In my case a small PNG grabbed from our website. Make sure “Embed” is selected at the next window.

Press Ctrl + shift + r to bring the document size to the image border.

Whilst the image may appear sharp here closer inspection shows us the limits of that.

Tracing the Edges

Now with the image loaded we can navigate through the Path menu → Trace Bitmap or Shift + Alt + b for speed. With the image selected press “Update” to run a single scan and detect the edges of the shape. Press “OK”.

Cleaning Up the Path

Select the Node too (n) and click on the image.

As we can see the software picked points along the straight edges. These are easily editable by dragging or deleting. working through each of these and removing them then converting the corners from bezier curves to straight corners allows us a sharp infinitive scale-able image to work with.

From here Export as SVG then load to whichever CAD software can accept it and you can begin advanced editing.

Why?

This method could very well be seen as cumbersome, labour intensive, slow or inefficient which isn’t necessarily false. The thing that excites me is the new avenue that I can lean on to solve the next problem. Furthermore, being aware of this method will open your eyes to new solutions to as yet undefined problems.

An idea that I’m going to play with is for a 3D printing storage project I am working on. I’m trying to organise my tools at home so I plan to lay some small tools on a sheet of A4 paper. Take a photograph and crop to the edges of the sheet. from there I will use Inkscape to trace to outline and bring this to CAD. Then create custom housing for all my tools.

Aside from the practical. It’s nice to shake things up and dabble in a new skill. It’s great to break free and find a new path even for the sake of exploring alone.

About the Author

Robbie is a motivated, focused, and dedicated Laser Engineer at A-Laser. Robbie studied Manufacturing Systems Engineering at Glasgow Caledonian University, graduating in 2013. He then took a graduate role at Tannlin Technology in the UK where he worked on the systems team. His role included product improvement, customer assistance, system building, and engineering analysis. His five years of experience working at Tannlin, often in the field, required thinking on his feet and working with limited resources. Outside of engineering, Robbie enjoys photography, as he likes to keep a part of his life in a creative field so that he can work that muscle when he needs to. Robbie excels in roles that combine technical expertise and project coordination and strives to deliver value to customers. Robbie is highly appreciated for his client-centric approach and his ability to build strong client relationships. If you have questions or want to discuss laser technology, please reach out to Robbie!