From CAD to Part: How Custom Laser Cutting Speeds Up Prototyping

From my early experiences with custom laser cutting manufacturing, it was obvious that by providing this type of service, it was a continuous request for support from start-ups and OEMs. Laser cutting has been prominent in providing prototypes for projects not only in Silicon Valley, but through online ordering, the outreach for R&D and custom prototyping support comes worldwide. Custom laser cut flat 2D geometries has progressed over the past 15 years to be a highly regarded solution in processing thin gauge materials from polymers to exotic metal alloys. The active nature of developing new technologies relies on receiving and reviewing of prototypes. The evaluations lead to further iterations, which leads to additional testing.

The reason why laser technology can speed up prototyping and is a great solution for numerous industries and applications is the flexibility, reliability, and accuracy of the technology. Key points of how custom laser cutting technology can speed up prototyping are:

- Rapid Set-Up: Laser systems typically do not require tooling to proceed with laser cutting materials. The technology for many system types is non-contact. What is needed to proceed is the CAD data file and the material of choice.

- Accuracy: Precision laser cut components are produced accurately to a +/- 0.5 mil to +/- 2 mil. Project details and material do affect the tolerance that can be achieved.

- Multiple Iterations: Being able to switch from one iteration to another without drastic set-up changes, allows for review and testing of laser cut parts, in a short amount of time.

- Material Flexibility: Many laser systems can cut a multitude of materials. This can improve the progression of prototyping by being able to use on machine. Examples such as:

- UV Laser Technology- Kapton, PEEK, FR4, copper, gold/copper, Graphene, stainless steel, aluminum.

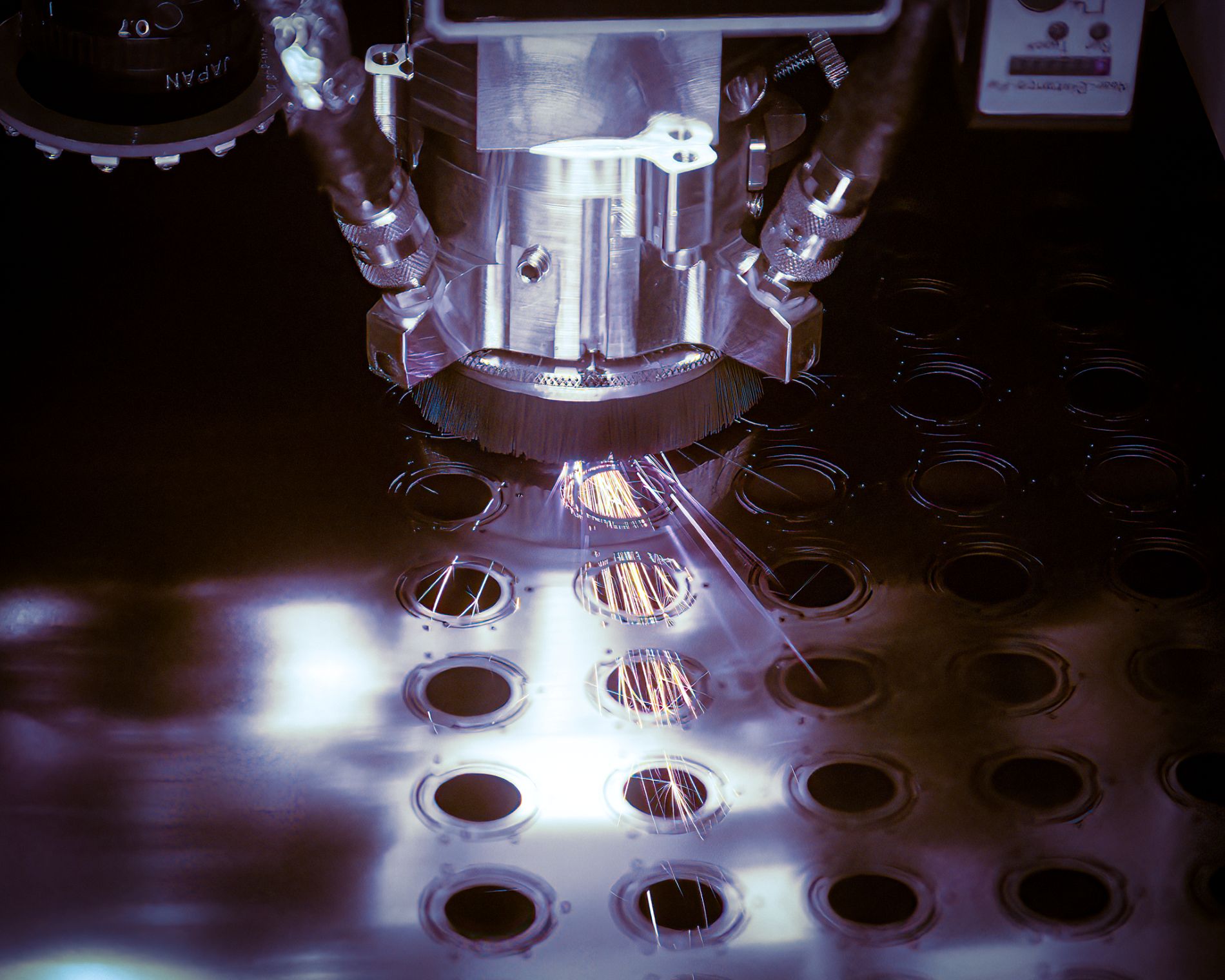

- Fiber Laser Technology– aluminum, tungsten, titanium, copper, brass, alumina ceramic.

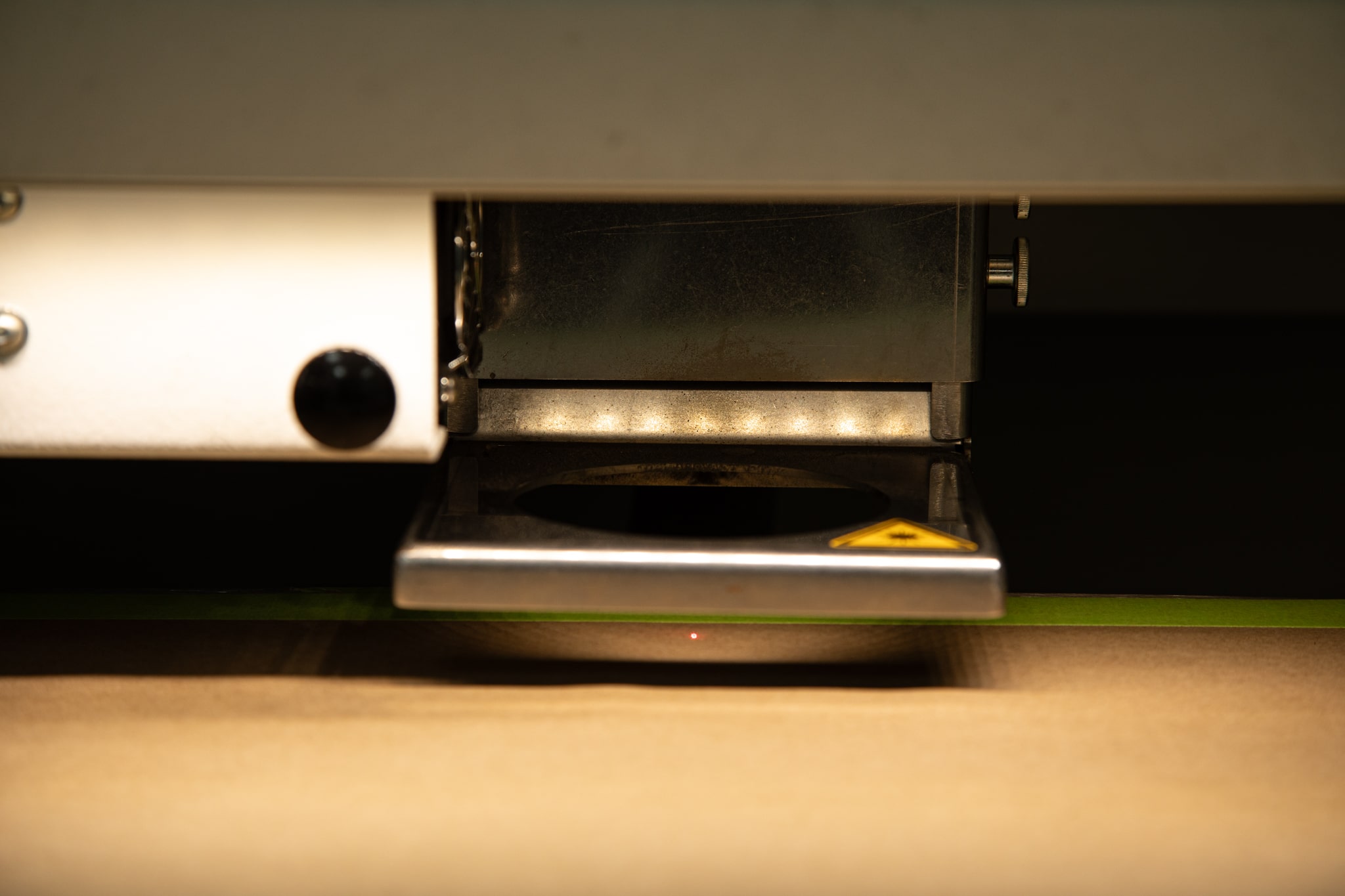

- CO2 Laser Technology- clear plastics, wood, paper.

- Reliability: Laser cutting machines are highly reliable in their function with scheduled maintenance. There are no dies or bits to wear down, nor is there much mechanical stress incurred into the laser machines

- Volume Manufacturing Options: Volume manufacturing does not speed up the prototyping function, but it can speed up the transition from prototype to evaluation runs and finally production. Custom laser cutting technology can be a great incentive knowing the technology being used in R&D and prototype, can be used for high volume runs.

Prototyping is part of the process in developing new technologies and the push for rapid results is supported by custom laser cutting services. Laser systems such as ultraviolet, CO2, fiber, pico-second, femto-second, and others being available as a manufacturing solution. The decision to use each depends on the factors of the project. This determination is made through experienced laser manufacturers who can direct the best technological solution for new ideas that come forward and request the support that only laser manufacturing can provide.