Laser Cutting Polyester

Biaxially Oriented Polyethylene Terephthalate or better known as BOPET, is also commonly known as polyester film. Polyester film’s incredible barrier properties against gas and moisture have made it an essential component in modern applications. When it comes to laser cutting, precision is a key factor in choosing this method of manufacturing. Laser technology excels in providing highly complex and customized components out of many materials that can be challenging when produced or attempted by other manufacturing techniques. However, much of laser precision manufacturing is still a mystery to many. To help clarify what lasers technology can provide for polyester film, the following questions and answers are submitted below.

Controlled Precision

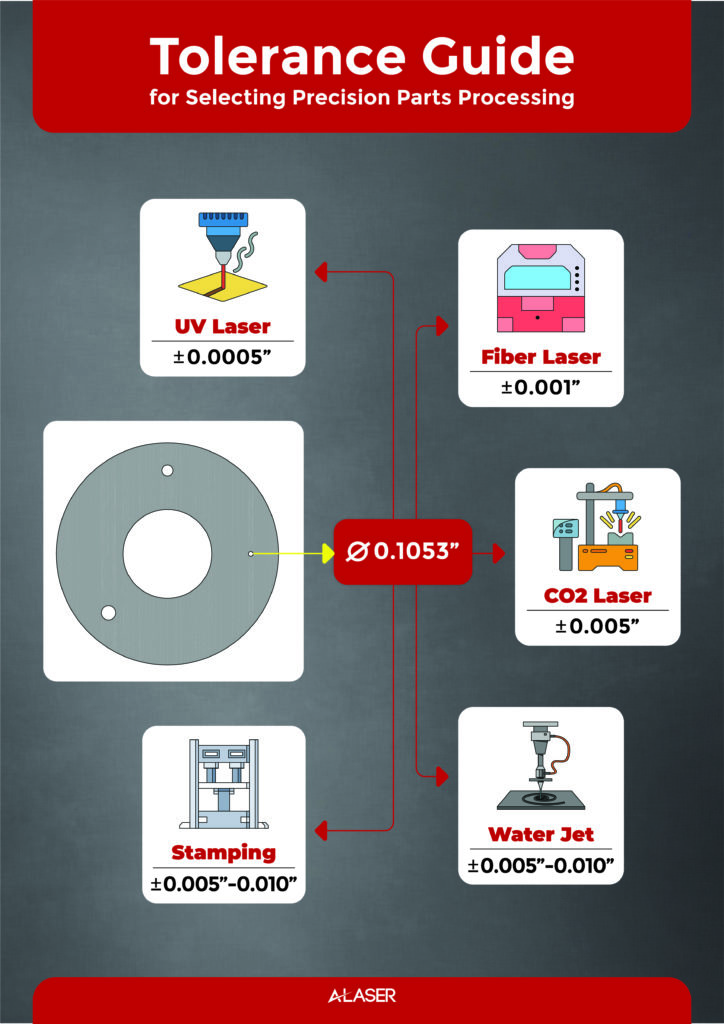

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Polyester Films?

Tight tolerances guarantee that every part, from intricate gaskets to high-tech display components, fits perfectly into their final assembly. There’s no room for error when creating precise electronics or components used in medical devices. Laser manufacturing technology is solution for many tight tolerance components. Laser cutting of polyester will be done on an ultraviolet laser system using a narrow beam diameter of 20 um, the tolerances being held are +/- 1mil for polyester film. Factors that can affect the tolerance are:

- Film Thickness: Lasers cut with light energy and do it very well, but as material thickness increases, more energy is needed. Tolerance control will be slightly larger.

- Material Type: Polyester film can come in various forms, with and without adhesives or perhaps some special coated layers. This variable can affect how tight a tolerance can be.

- Design Complexity: Highly intricate designs with very small features or tight curves may require specific adjustments to maintain optimal tolerance. This can also increase manufacturing time if the cutting process needs to be slower.

Key Manufacturing Differences

How Does Laser Cutting Compare to Die-Cutting, Waterjet, or CNC Machining of Polyester?

It’s difficult to compare one manufacturing method to the other since they all are different in the process and all have unique attributes that are positive to their use. Comparisons are better understood when focused on aspects such as capabilities. In regard to polyester film, the table below focuses on those differences.

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Laser Cutting | Complex shapes, prototyping, and small to medium volume runs of thin gauges of metal alloys, polymers, gasketing materials. | High precision for intricate designs. Non-contact process prevents material distortion. Seals edges, preventing fraying. | Thermal process can cause a slight heat-affected zone (HAZ) or discoloration. Limited to thinner gauges of materials. |

| Die-Cutting | High-volume production of simple, uniform shapes. | Extremely fast and cost-effective for large batches. Highly repeatable with consistent results. | High initial tooling cost for the custom die. Mechanical pressure can stress the material. Not suitable for complex or delicate geometries. |

| Waterjet Cutting | Thicker films, laminated materials, or applications where heat is a concern. | Cold process with no heat-affected zone. Cuts very thick materials. | Slower than laser cutting for thin films. Water pressure can cause material rippling. May leave a rougher edge. |

| CNC Machining | 3D shapes or applications requiring features like pockets or countersinks. | Highly versatile for creating three-dimensional components. | Not ideal for thin films due to the physical force of the tool. Can tear or distort the material. Slower and more expensive for simple 2D shapes. |

Understanding HAZ

What Edge Quality Can Be Expected When Laser Cutting Polyester Film and Are Burrs or Heat-Affected Zones (HAZ) Present?

As a non-contact process, laser cutting of polyester film results in smooth profile edges, that have precision and high quality that are in demand for today’s industries. Laser cutting however is thermal process and care must be taken to prevent unwanted HAZ (heat affected zones) from occurring. This is done by adjustment of the laser parameters or laser “tool”, which consists of numerous factors including some prominent ones such as:

- Laser Power and Speed: Adjusting the wattage or power that the beam is cutting with. Speed is for how fast the laser cut path or cycle is done. Reducing power and increasing laser cycles can eliminate HAZ.

- Laser Dwell Time and Entry/Exit Point: Dwell time is the time the laser is set before moving along the cut path. Laser entry and exit points can be adjusted to reduce the amount of energy as the laser begins and ends the cycle.

There are many more adjustments that can be made, and other factors such as the thickness of the polyester and the complexity of the design can affect the outcome of edge quality.

Material Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Polyester Film?

Unlike metals, which have high reflectivity and thermal conductivity, polyester film is an ideal material for laser cutting due to its properties. Its low reflectivity, low softness, and low thermal conductivity allow for clean cuts with minimal burrs and excellent tolerance control.

Reflectivity:

Polyester film is not highly reflective compared to metals, which means most of the laser energy is absorbed efficiently which is good for consistent cutting. This low reflectivity results in sharp, well-defined edges and making it easier to hold tight tolerances.

Softness / Mechanical Strength:

Polyester film is relatively soft and flexible. During cutting, this means the material doesn’t resist the laser beam, but it does need to be secured to prevent warping, curling, or shifting during the cutting process. The impact on edge quality can be minimal to none as polyester cuts fast. However, being thin and pliable can have concerns for dimensional stability if the proper controls are not input.

Thermal Conductivity:

Polyester has low thermal conductivity, meaning heat doesn’t dissipate quickly. The energy stays localized, which is beneficial for efficient cutting — but it also raises the risk of melting or heat-affected zones (HAZ) if not controlled.

More Than Just a Cut

What Are the Benefits of Laser Cutting Polyester Film?

Laser cutting polyester film offers a unique blend of precision, cleanliness, and flexibility that traditional cutting methods can’t match. Because the process is non-contact, the film isn’t stressed or deformed, allowing for tightly controlled tolerances and intricate designs with smooth, sealed edges free from fraying or burrs. With no need for custom tooling, it’s highly cost-effective for both prototyping and production, while also minimizing material waste through narrow kerfs and efficient nesting.

Ready to Create Your Perfect Part?

Whether for electronics, medical devices, or specialty packaging, laser cutting ensures consistent quality and complexity at scale, making it the preferred choice for manufacturers who demand both accuracy and efficiency. Laser cutting polyester film strikes the ideal balance of precision and efficiency, delivering tolerances often within ± 1 mil that far exceed what die-cutting or waterjet can reliably achieve, and without the tool wear or mechanical stress seen in CNC machining. While care must be taken to manage heat input and avoid edge discoloration on very thin films, the benefits—tight tolerances, intricate geometry capability, and no tooling costs—make laser cutting a clear advantage over traditional methods when it comes to producing high-quality, complex polyester film components.