Laser Etching vs Laser Engraving: What’s the Difference?

A Guide to Choosing the Right Method for Your Needs

Laser etching and laser engraving are both advanced laser techniques, that differ in their processes, applications, and outcomes. There are key distinctions between laser etching and engraving that will be highlighted to assist in determining the method that works best for specific materials or projects.

What is the Difference Between Laser Etching and Engraving?

Though laser etching and laser engraving share similarities, they both use laser technology to alter the surface of a material, yet they are distinct techniques with unique outcomes. The following will highlight their differences and focus on what depth, durability, and design factors should be considered?

Laser Etching

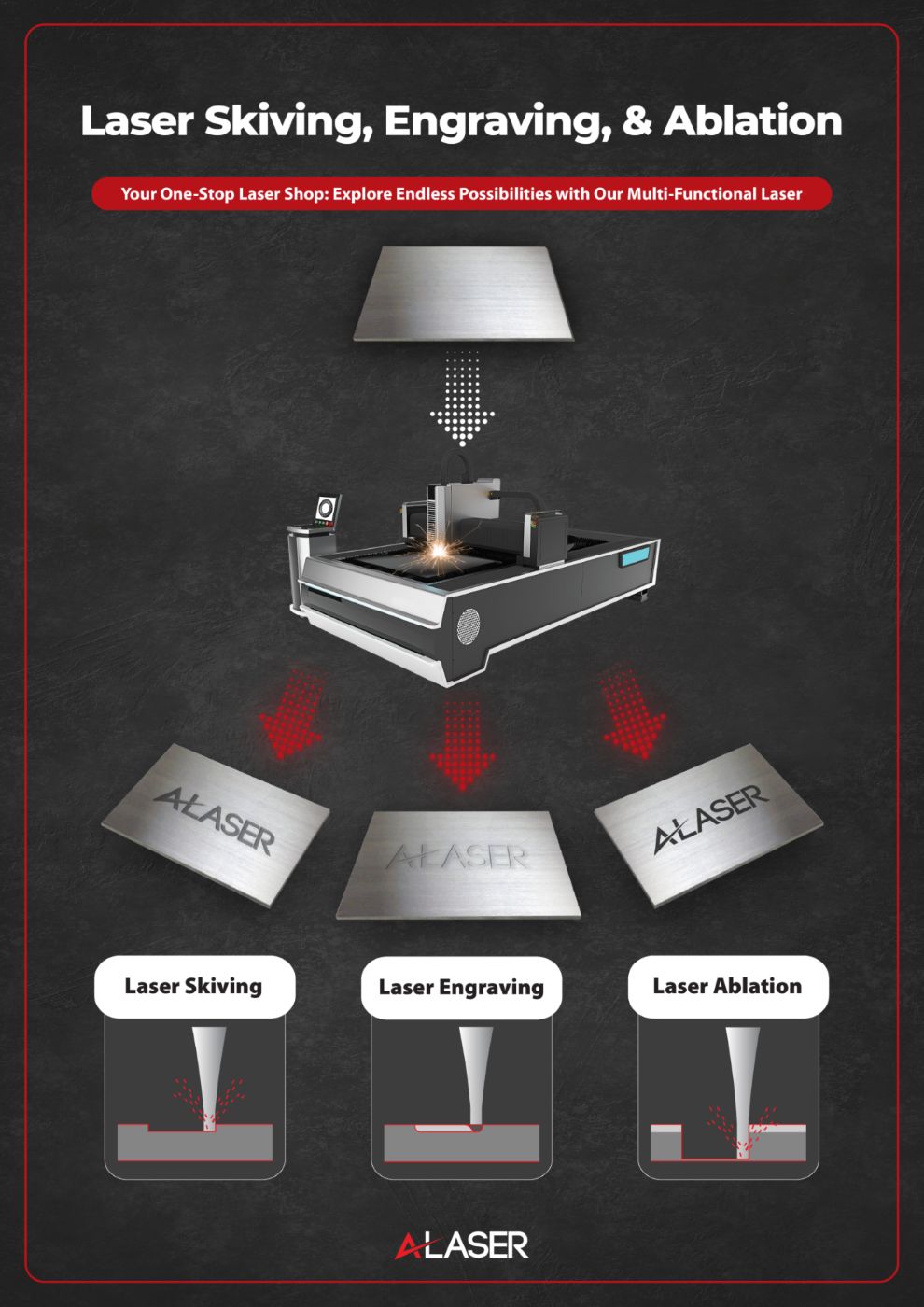

Laser etching is the process of heating the surface of a material with a laser beam. This causes the surface to be slightly ablated and melt creating a raised mark. This method doesn’t remove much material but instead alters the material’s surface properties. Etching is commonly used for adding logos, serial numbers, or other designs onto metals, ceramics, and certain plastics.

The key characteristics of laser etching are:

- Depth: Etching typically penetrates only up to 0.001″ into the surface. If shallow markings suffice, such as for branding or decorative purposes, laser etching is ideal.

- Speed: It is faster than engraving as it requires less energy and minimal material removal.

- Applications: Ideal for shallow marks and materials with specific color or texture changes. Laser etching is faster and will cost less than engraving. Better for internal identification and areas of little exposure to environmental changes and wear.

- Durability: Good for moderate and short-term use. Laser etching is sufficient for designs or marks that do not face heavy physical wear or for parts that will be one time use only.

- Design and Aesthetics: Produces a smoother, raised finish, suitable for logos or text requiring high contrast.

Laser Engraving

Laser engraving is different because it removes material from the surface to create a recessed marking. The laser ablates deeper, vaporizing the material, leaving a permanent indentation. This method creates deep and highly durable marks for applications requiring legibility and permanence such as on products, industrial applications, and where the markings may be subjected to environmental changes.

The distinguishing features of laser engraving include:

- Depth: Engraving can reach depths of 0.003” up to 0.125″, depending on the material and application and laser systems used.

- Durability: High usage parts is best done by laser engraving. It offers great durability and is the best choice for components exposed to chemicals, or extreme temperatures. The marks are more resistant to wear and tear, making them suitable for heavy-use environments.

- Applications: Best for creating deep, detailed designs on metals, wood, glass, and some plastics. Uses for barcodes, identification, logos, and other nomenclatures that need longevity.

- Design and Aesthetics: Creates a recessed, textured effect, ideal for intricate patterns or designs with depth.

In summary, etching alters the surface finish for a raised mark, whereas engraving removes material for a recessed mark.

Which Method Is Best for Your Material?

The choice between laser etching and engraving depends on several factors, including the type of material, the intended purpose of the marking, and the desired visual or functional outcome.

Material Considerations

- Metals: Laser engraving is ideal for metals like stainless steel or aluminum that require deep, permanent marks. For decorative purposes or serial numbers, laser etching can offer faster results.

- Plastics: Certain plastics respond better to etching due to their melting points, allowing for crisp, clear marks with minimal depth.

- Glass and Ceramics: Engraving is preferable for glass and ceramics as it leaves a textured, frosted effect that is durable and visually striking.

- Wood: Engraving offers intricate and deep designs suitable for artistic or functional purposes. Etching is rarely used on wood.

Conclusion

Choosing between laser etching and laser engraving ultimately depends on the specific requirements of your project. Laser etching is faster and ideal for shallow, high-contrast marks, while laser engraving offers durability and depth for long-lasting applications. By considering factors such as material type, depth, durability, and aesthetic goals, you can select the method that best aligns with your needs. If you’re still not sure what method of laser marking your project will need, don’t hesitate to reach out to your local provider. Whether you’re working on industrial parts, personalized gifts, or creative projects, laser service providers will evaluate and determine the best method to use. Good luck on your next project!