What You Need to Know About ITAR-Compliant Laser Manufacturing

Compliance in ITAR laser manufacturing services isn’t just a certification; it’s a commitment. It means we operate with the utmost integrity, safeguarding sensitive defense-related information and technologies to protect national security. When your project demands uncompromised precision and absolute confidence, our ITAR-compliant laser cutting services deliver more than just parts – we deliver peace of mind. What exactly is ITAR? ITAR stands for International Trade in Arms Regulations that is a U.S. government regulation that controls the export and handling of defense-related materials, technologies, and information. In manufacturing, ITAR compliance means more than just paperwork. It ensures that sensitive parts and data, such as components for military aircraft, satellites, or weapons systems, are produced, stored, and shared only with authorized U.S. persons or entities. For manufacturers, being ITAR-registered signals a commitment to national security, traceability, and responsible supply chain practices, often opening doors to high-level defense and aerospace contracts.

Applications for ITAR Laser Cutting

Actual ITAR projects and information about them cannot be divulged, but we can discuss the types of support laser manufacturing is being sought for. Now you would generally think that ITAR work comes directly from the United States Government, but it does not. ITAR manufacturing is done by defense contractors or contractors that may specialize in muti-industry manufacturing but be ITAR complaint. A contractor working in electronic connectors may have an need for laser precision components that in turn will be used in missiles or military communication devices. One outstanding benefit is the opportunities laser manufacturing can gain is being ITAR compliant. The following list are examples of industries relying on laser ITAR certified components:

- Defense and Aerospace: Preventing leaks of fluids and gases is extremely vital and having precision cut gaskets is a must for all industries. Laser cutting of gasket materials of Grafoil, are used for their performance under pressure and in varying thermal environments. Gaskets also can be made from other materials.

- Nuclear Research: National Labs take advantage of lasers, using components for areas of research in nuclear science and related areas.

- Space Telecommunications: Creating better signals with encryption are essential and laser cutting machines provide components made from copper, nickel and polymers for space telecommunications.

- Optics: For sensors to firearms, Optical systems are complex and rely heavily on the assemblies of many different materials. Laser cutting has seen projects for optical shutters and aperture stops and other light manipulating components. These can be made from metal alloys to specialized light blocking material called SOMABLACK.

- Electronics: Even used in support of defense work, need ITAR controls. These types of projects are a great example of multi-industries working together and all will be ITAR certified. For laser cutting specialists, their expertise come is the form of laser depaneling (the singulation of multi-panel PCB assemblies) and laser solder mask removal. The precision of laser technology allows for complex board designs to be cut while keeping highly sensitive electronic components from vibratory and thermal stress.

Many industries are ITAR certified in providing materials, nuts and bolts, adhesives, metrology equipment and so many other facets. The cooperation between defense contractors and industry specialists who are ITAR certified helps create systems and tools that keep our country and our military personnel safe.

Meeting The ITAR Requirements

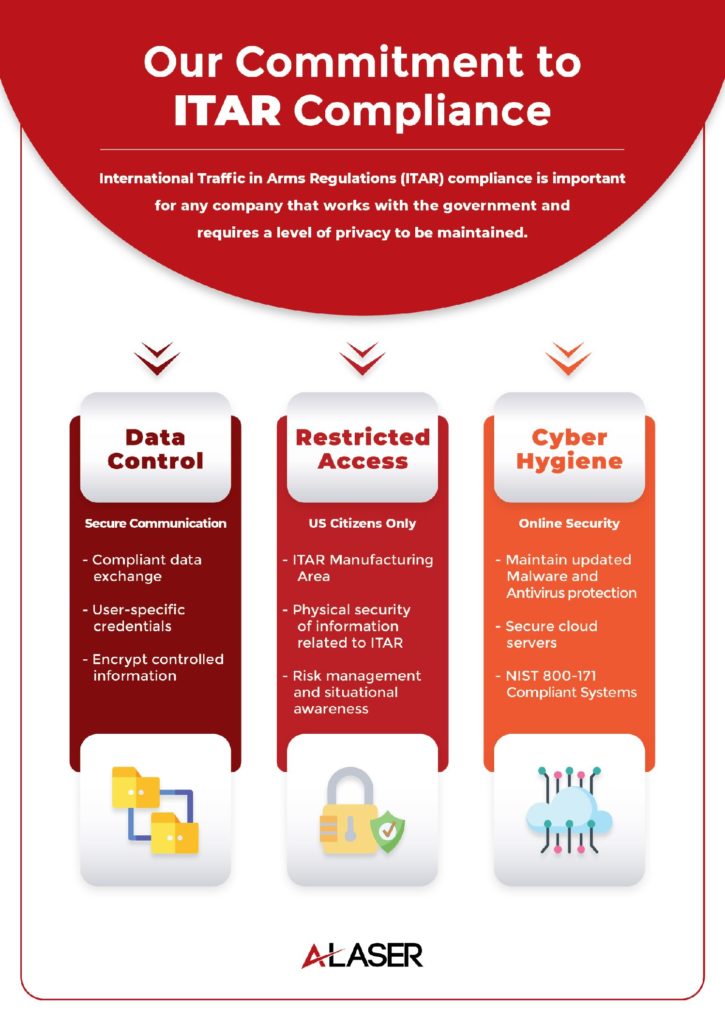

To become ITAR certified laser manufacturing will follow guidelines such as:

- Controlled Facility Access

ITAR-compliant laser shops restrict physical and digital access to authorized U.S. persons only, ensuring protection of defense-related technical data. - Traceability and Documentation

All laser-cut parts are tracked with detailed records, including material certifications, revision control, and job history—key for ITAR audits. - Secure Data Handling

Design files (e.g., DXF, STEP) are stored and transferred through encrypted, ITAR-compliant systems to prevent unauthorized access or export. - Trained Personnel

All staff involved in ITAR projects are trained on compliance protocols, ensuring sensitive information and parts are handled appropriately. - Controlled Technology Use

Only ITAR-approved laser cutting machines and software are used, with restricted settings and updates to avoid unintended data exposure. - Industry Focused

Common ITAR laser-cut components include aerospace brackets, defense enclosures, targeting optics mounts, and UAV parts—requiring both precision and compliance.

This blend of precision manufacturing and strict compliance ensures laser cutting remains a trusted process for defense and aerospace industries.

Conclusion

ITAR manufacturing, when coupled with laser technology, produces some of the best precision components being made under high standards for quality, repeatability and traceability. This partnership will continue to be a key part of the making future technology today.