Why Laser Cutting Is Ideal for EV Battery Insulators and Spacers

For components like insulators and spacers used in EV batteries, there has been an increasing need for laser precision. In most cases for manufacturers, there is always more than one way to produce a precision component, and you will find arguments for and against one method over another. Being part of laser manufacturing, I acknowledge the bias I have regarding EV battery insulation laser cutting and EV spacer cutting, but it is done so with great respect and admiration for the other manufacturing methods I will mention. Industries seek out manufacturing for support and many times specific sectors of an industry will seek out a manufacturing process that fits well with the end goal. EV vehicle manufacturing, just like any other automotive manufacturing, has so many parts that come together. One aspect of and some might consider the heart of EV technology is batteries. EV batteries are the power source that millions of vehicles now run on. The need to be as efficient in use and sufficiently charged is important to customer satisfaction and the overall performance of the vehicle. EV battery insulators and spacers are part of a highly technological device and require precise control in their manufacturing. This is why I feel laser cutting is an ideal method. Let’s explore more on how laser cutting for electric vehicles has become a valuable supply chain member.

Versatility Keeps Options Open

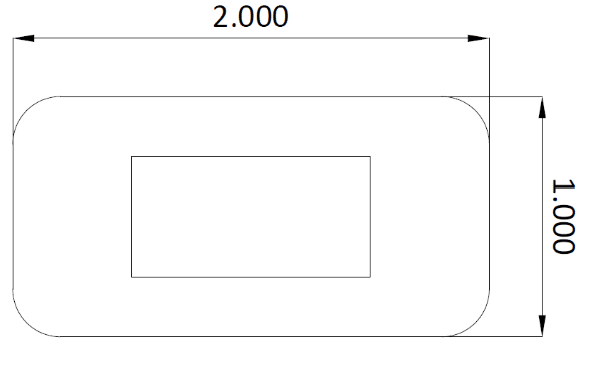

If you have a project in early development, and now the next phase would be to acquire some prototypes, laser cutting will be a great way to go. Many times, laser cutting is the only way to process early prototype needs for flat 2D geometries, that will be made with high precision that often exceeds the required tolerances for R&D work. In developing EV battery insulators, the process will be to produce iterations of the design, coupled with adjustments to the laser parameters or “laser tool”. Unlike other flat component manufacturing companies such as die-cutting or stamping that have challenges to support R&D because cutting dies need to be made. These can be made from lesser quality materials and done so more rapidly, but they will need to be remade for production quantities. If any changes occur through the die-cutting or stamping process, this can be very expensive. On the other hand, for changes with laser manufacturing, adjustment to the CAD file is all that is needed. Laser cutting is a non-contact process that does not inflict physical damage to the material. Another key positive attribute to laser cutting technology is its material versatility. For EV spacers, insulators, connectors, heat shields, and other components, using lasers can speed up the evaluation process as no set-up is needed, other than switching to a new material and uploading the new CAD file. Examples of the variety of materials cut with laser technology in support of EV batteries are shown below:

- Polyimides-UV

- Copper-UV and Fiber Laser

- Nickel-UV and Fiber

- Aluminum-UV and Fiber

- Steel- Fiber

- Graphite-UV and Fiber

- Lithium- UV and Fiber

- PEEK-UV

- Stainless Steel-UV and Fiber

These and more materials are readily cut using systems like ultraviolet and fiber lasers, for example. Ultraviolet technology is the type of laser that does have the most versatility in types of materials that also include rubbers like nitrile and silicon types, adhesives, FR4, alumina ceramic to name just a few more. The focus on UV cutting is the thin gauges of materials, from 0.0127mm up to about 0.254mm using a beam diameter of 20um. The range of cutting thickness is narrow, but the edge quality is high. For thicker metal alloys cut for EV technology, fiber lasers can handle cutting upwards of 0.5mm, 4mm to10 mm for many systems. Fiber lasers cut faster and have beam diameters of 18um to 35um, for example. Laser technology has the flexibility to cut just one or two parts but can rapidly change gears to support volume production.

Quality Keeps the Power Going

Another reason laser cutting is ideal for EV components is the quality and level of reliable precision that can be achieved. Using small beam diameters as mentioned of 20um, 18um and 35um, for example, finer features are created that other methods would have challenges to produce. Feature accuracy is a vital aspect of precision manufacturing. Holding micro sized dimensional details of components is what laser cutting offers. Lasers, like many other manufacturing techniques, come in multitudes of sizes and capabilities with some being relatively simple to operate to those with more complexity but have more refined adjustments. An industry badge of honor is that from smaller systems to those of larger sizes, the accuracy of is very precise. For EV battery components, holding tolerance of +/- 0.0254mm is standard. Tolerances at a +/- 0.127mm are considered a large tolerance, indicating the accuracy these cutting machines have. Control of the cutting parameters is important to hold accuracy. There are many used, but here is a brief overview of how laser cutting machines adjust parameters for these tight tolerances:

- Power: Lasers can be adjusted incrementally on power to create just the right amount to cut through cleanly a material. It is not uncommon for a 400-watt system to be adjusted at .1watts increments.

- Speed: The speed at which the laser head moves greatly influences the cut edge quality and the roughness of the surface.

- Laser Focus: Focusing the beam to be at its prime focus per the type of material being cut.

- Passes: Lasers cut by a series of passes or runs. This gives better control of the cut quality and precision to cut features. The number of laser passes is affected by the material type, thickness, and geometry.

- Dwell Time: How long the laser sits or rests before resuming another cut is the dwell time. This is important to help control any slag, burrs or heat affected zones or HAZ.

The culmination of parameters is called the “laser tool” and will be unique to each cutting project. Stored indefinitely, this results in parts being done to exact dimensions as previous lots for ongoing and future production runs.

For first-time customers in the EV battery industry, laser cutting emerges as a transformative solution for manufacturing insulators, spacers, and other components. Its unparalleled precision ensures that even the most intricate designs are achieved with micro-level accuracy, reducing waste and ensuring optimal performance. Furthermore, the adaptability of laser systems to handle varying materials and thicknesses from thin insulators to robust spacers makes it a versatile choice for diverse project requirements. The ability to store cutting parameters for consistent, repeatable quality in future production ensures reliability and efficiency, while the speed of fiber lasers supports large-scale demands without compromising on edge quality or dimensional integrity. For those seeking cutting-edge technology that marries innovation with practicality, laser cutting provides an investment in superior craftsmanship and long-term savings, aligning perfectly with the high standards and rapid evolution of the EV battery industry.