UV Laser Cutting Service High-Precision, Complex Patterns, No Charring

A-Laser knows the importance of focus in any business, and in the technologically complex world of lasers, it’s essential. With the use of ablation or synthetic erosion, ultraviolet (UV) laser cutters mimic the natural wearing away process. This state-of-the-art technology explodes material rather than melting it, creating a cleaner edge and less thermal impact. A-Laser ablation successfully handles polyimides, precious metals, and thermal substrates.

What is UV laser cutting & ablation?

Ablation is defined as removal or erosion of something. Ultraviolet laser ablation is the technology used to mimic the wearing a way of natural objects that are usually found in nature; like the erosion of rock or evaporation of snow.

The UV laser ablation process explodes material rather than melting it, which results in a sharper, cleaner edge and less thermal influence when laser cut. A-Laser operates on a wide range of materials with our UV laser ablation systems, from SOMABLACK to precious metals, thermal substrates, adhesives, and even laser cut polyester. Additionally, these materials are seen with adhesive combos that are clad or bonded. Our UV ablation specialists have built a vast library of tools to accommodate these various material combinations, their thicknesses, and cut requests of our customers.

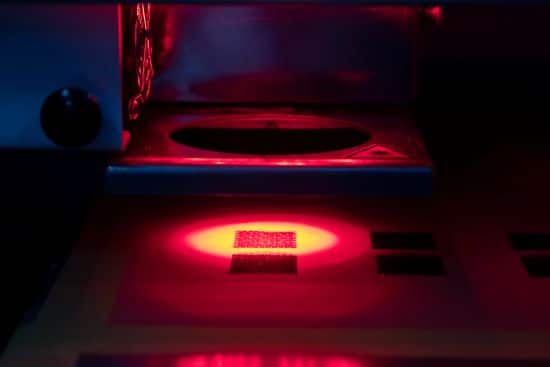

By utilizing UV laser ablation, we can achieve incredibly intricate and complex patterns without charring the material and maintaining tolerances of +/- 12 microns or .0005″.

Ultraviolet (UV) Laser ablation will produce finely cut and detailed features in precision parts manufacturing for industries ranging from medical to engineering. This application is typically used on non-metal parts but can also be used on ultra-thin metal as well.

UV Lasers for Precision Cutting

UV, or ultraviolet, lasers operate within the ultraviolet spectrum, boasting a shorter wavelength that renders them exceptionally well-suited for precision applications, holding tolerances up to 0.0005”. UV lasers play a vital role in PCB manufacturing. They are employed for tasks such as cutting, drilling, and marking on circuit boards, ensuring the accuracy needed in electronic components. They can process precision laser cut parts with materials such as Kapton, Grafoil, SOMABLACK, PEEK and more. The advantages of UV lasers include:

- High Precision, up to 0.0005”: UV lasers excel in delivering intricate and precise results, making them indispensable for applications demanding utmost accuracy – up to 0.0005”.

- Ideal for Intricate and Delicate Materials: With their fine-tuned precision, UV lasers prove to be ideal for working with intricate and delicate materials, contributing to the versatility of their applications.

- Efficient for Diverse Materials: The versatility of UV lasers shines through as they efficiently cater to a broad range of materials, showcasing adaptability across various industrial requirements.

- Suitable for Cutting and Marking: Whether it’s cutting or marking, UV lasers prove to be efficient in both applications, providing a multifaceted solution for material processing needs. Although, it is not a solution for serialization.

The UV laser ablation process explodes material rather than melting it, which results in a sharper, cleaner edge and less thermal influence when laser cut. A-Laser operates on a wide range of materials with our UV laser ablation systems, from SOMABLACK to precious metals to thermal substrates. Additionally, these materials are seen with adhesive combos that are clad or bonded. Our UV ablation specialists have built a vast library of tools to accommodate these various material combinations, their thicknesses, and cut requests of our customers.

By utilizing UV laser ablation, we can achieve incredibly intricate and complex patterns without charring the material and maintaining tolerances of +/- 12 microns or .0005″.

Advantages of UV Laser Cutting with A-Laser

Quality Cutting

The UV laser has the ability to cleanly cut even the most complicated patterns with minimal stress. The laser allows for more circuits on a single panel, and has an integrated vacuum table. Operational costs that occur from outsourcing are eliminated due to the high-quality cutting and versatile processing.

Environmentally Friendly

The advanced dust and fume exhaust unit removes all debris, which results in a clean surface and no polluting of the work environment. These high-precision lasers are on the cusp of replacing environmentally unfriendly processes like chemical etching.

Quality Control

Laser measurement happens at the source, which ensures proper process monitoring. Creating custom laser tools allows the exact project parameters to be met with an unlimited amount of combinations and variations. The use of short wavelengths enables lasers to be precisely focused, creating very fine circuit features while still maintaining superior positioning accuracy.

Limited Thermal Stress

By operating at a low power level, A-Laser utilizes cold ablation, which produces a reduced heat affected zone (HAZ). Unwanted effects such as burning, charring or other thermal stress caused by high-powered lasers are avoided.

Frequently Asked Questions About UV Lasers

Kapton (Polyimide) and PEEK (Polyetheretherketone)

Two materials our laser cutting service sees often are Kapton and PEEK. Both cut very nicely on the UV laser cutting systems and both are used for highly technical applications in a wide variety of industries. For our purposes, we know that both Kapton and PEEK laser cut with very little carbon residue, hold tolerances very well, and laser cut with very clean edges. We are curious if anyone out there wants to debate the features and benefits of thermoset vs thermoplastic films such as Kapton and PEEK. Our laser cutting service works with a wide range of engineers, so it would be very interesting to hear input from the various industries.