Precision Parts

Precision Parts

How Important Are Precision Parts for Innovation and Manufacturing?

Precision parts, the intricate components that form the backbone of modern manufacturing, have been essential to human progress for centuries. From the finely crafted gears of medieval clocks to the microchips that power today’s computers, the pursuit of precision has driven innovation and technological advancement. A precision part is a component manufactured with extreme accuracy and precision, often requiring tolerances that are measured in microns or even nanometers. These parts are characterized by their intricate designs, complex geometries, and high-quality finishes. They are essential for products that demand exceptional performance, reliability, and functionality, as societies have evolved and demands have grown, the importance of precision parts has only intensified. In today’s world, where products must be increasingly efficient, reliable, and sophisticated, precision parts play a more critical role than ever before. Precision parts are the cornerstone of modern innovation and manufacturing. Their accuracy, reliability, and consistency are essential for creating products that meet the demanding standards of today’s consumers. From high-tech electronics to critical medical devices, precision parts drive advancements across a wide range of industries. The following table highlights some of the important factors of precision parts:

| Industry | Key Importance of Precision Parts | Manufacturing Methods Used | Types of Precision Parts |

|---|---|---|---|

| Aerospace | Safety, performance, reliability | Laser cutting, CNC machining, wire EDM, water jet cutting | Critical components like aircraft engines and control systems require extreme precision for safety and performance. |

| Automotive | Efficiency, fuel economy, performance | CNC machining, stamping, die-cutting, laser cutting | Engines, transmissions, and suspension systems contribute to vehicle performance and fuel efficiency. |

| Electronics | Functionality, miniaturization, reliability | Laser cutting, CNC machining, wire EDM | Microelectronic components and printed circuit boards enable the miniaturization and functionality of electronic devices. |

| Medical Device | Safety, efficacy, precision | Laser cutting, CNC machining, wire EDM, water jet cutting | Surgical instruments, implants, and prosthetics ensure safety, accuracy, and patient outcomes. |

| Energy | Efficiency, sustainability, reliability | Laser cutting, CNC machining, water jet cutting | Turbines, generators, and solar panels contribute to energy efficiency and sustainability. |

| Consumer Goods | Quality, durability, aesthetics | Laser cutting, CNC machining, stamping, die-cutting | consumer electronics, watches, and other products enhance their quality, durability, and appearance. |

Precision parts manufacturing is driving innovation and improving manufacturing processes across a wide range of industries including medical devices, optics, alternative energy, semiconductors, aerospace and so many more. As technology advances not only in the process but in materials used, innovation will continue to have numerous outlets to explore and take ideas from the computer to physical reality.

Precision Parts Impact on Industries from Simple to Complex Geometries

Precision parts, characterized by their intricate designs and exacting tolerances, have become indispensable components in a wide range of industries. From simple geometries to complex shapes, these parts play a pivotal role in enhancing product performance, reliability, and efficiency. Whether it’s a small electronic component or a large-scale industrial machine, precision parts are the building blocks that drive innovation and progress.

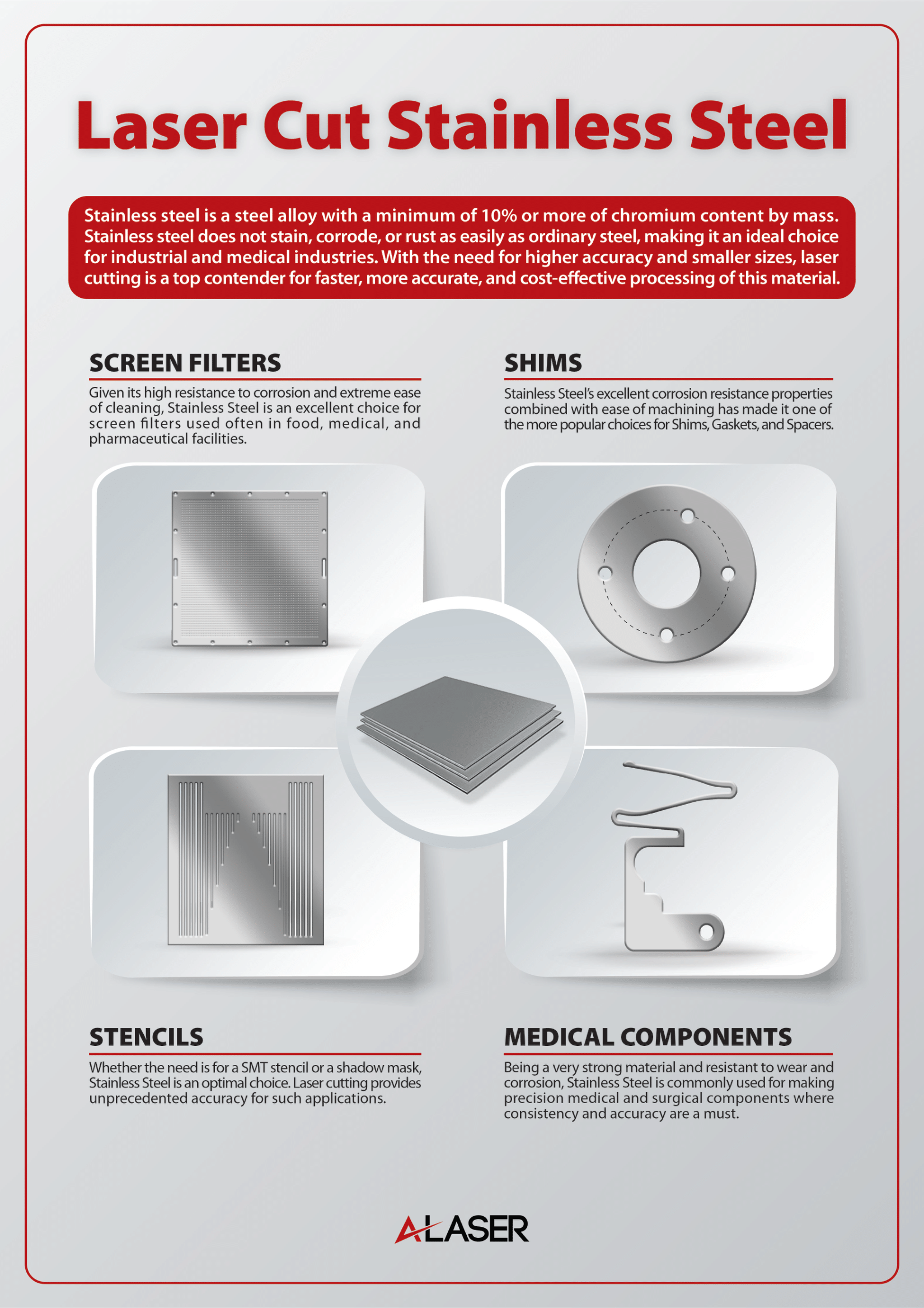

The impact of precision parts extends far beyond their physical form. Their ability to withstand rigorous demands, maintain precise functionality, and contribute to overall product quality has made them essential in industries ranging from aerospace and automotive to medical devices and consumer electronics. As technology continues to advance, the need for precision parts will only grow, driving manufacturers to explore new materials, processes, and design techniques to meet the ever-evolving demands of the market. One example of manufacturing is laser cutting. The infographic on stainless steel is an example of laser cutting technology creating different designs. The size of the parts also is scalable from extremely fine and delicate parts of 1mmx1mm to larger components over 500mm x 500mm or greater. Other methods have similar capabilities. As mentioned earlier, the importance of precision parts supports innovation from the R&D and prototype stage to production volumes. The following list are some examples of precision parts made for industry both in simple designs to complex:

- Light and Strong Components: Precision parts create intricate, lightweight components that meet the stringent weight and strength requirements of aircraft and spacecraft.

- Complex Brackets and Fixtures: Parts can be used to produce complex brackets, fixtures, and other structural elements with high precision and minimal waste.

- Automotive:

- Engine Components: Manufactured intricate engine components such as intake manifolds, exhaust systems, and turbocharger housings with high accuracy and efficiency.

- Body Panels and Frames: Precision manufacturing enables the production of complex body panels and frames with smooth edges and consistent tolerances, improving vehicle aesthetics and performance.

- Oil and Gas:

- Gaskets, shims and flanges are used in the oil and gas industry as well as many others needing to control fluids and gases and keep the integrity of the system intact. These sometimes-simple forms in many ways protect the public, personnel and the environment.

- Electronics:

- Circuit Boards: Laser cutting is essential for creating intricate circuit boards with precise cutouts and vias, enabling the miniaturization and complexity of electronic devices. Laser depaneling is also a service provided by laser cutting service providers.

- Metal Enclosures: Laser cut metal enclosures provide protection and support for electronic components while maintaining a sleek and modern design.

- Medical Devices:

- Surgical Instruments: Highly precise surgical instruments with complex geometries and sharp edges, improving surgical outcomes and patient safety.

- Prosthetics: Components can be used to create customized prosthetic limbs and devices with a high level of precision and durability.

How Can Precision Parts Be Integrated into Manufacturing Assembly Volumes?

The journey of a precision part from its conception in research and development (R&D) to its integration into high-volume manufacturing assemblies is a complex process that requires careful planning and execution. This transition involves overcoming numerous challenges, including scaling up production, ensuring quality consistency, and optimizing costs. Successful navigation of this path is critical for companies seeking to commercialize innovative products and maintain a competitive edge in the market with steps like:

Scaling Up Production: One of the primary challenges in transitioning precision parts from R&D to high-volume manufacturing is scaling up production. This often involves investing in specialized equipment and machinery, hiring additional staff, and optimizing manufacturing processes. To ensure a smooth transition, companies must carefully evaluate their production capacity and identify potential bottlenecks. Additionally, it is essential to establish robust quality control measures to maintain consistency throughout the scaling-up process.

Ensuring Quality Consistency: Maintaining quality consistency is paramount when transitioning precision parts from R&D to high-volume manufacturing. Any deviations from the original specifications can have significant implications for product performance and reliability. To address this challenge, companies must implement rigorous quality control systems, including inspection procedures, statistical process control, and continuous improvement initiatives. Moreover, it is crucial to invest in advanced measurement technologies and metrology equipment to ensure that manufactured parts meet the required tolerances and standards.

As technology continues to evolve and consumer expectations rise, the demand for precision parts will only grow. Companies that can effectively transition from R&D to high-volume manufacturing will be well-positioned to capitalize on emerging opportunities and maintain a competitive advantage. By embracing innovation, investing in advanced technologies, and fostering a culture of quality, manufacturers can ensure a seamless and successful journey for their precision parts.