PCB Fabrication & Lasers

Today’s modern world is filled with all sorts of electronic devices. You are surrounded by various technologies from the moment you wake up to the moment you go back to sleep.

All these devices, whether be it your phone, your TV, the computer you work on or even the systems in your car deploying your air bags and telling you to check your engine, have one thing in common. They all have Printed Circuit Boards (PCBs for short) hidden somewhere inside the design.

Without these PCBs, modern electronic designs would not have been possible, or at the very least it would be significantly different. These marvels of technology support and connect all the electronic components needed to make the magic happen.

Technology Changes

Because technology is always pushing the envelope and the limits for size, speed, and convenience, PCB fabrication has gone through many changes over the past 4 decades. From through-hole designs to surface-mount designs, from single layer boards to multi-layer boards, from chemically etched artwork to mechanically etched or laser ablated artwork… the changes are too numerous to count for this still-developing process.

PCB fabrication has turned into a science of its own, a discipline concerned with the right choice of laminates, substrates and even copper thicknesses that fit all the needs of the different electronic designs.

One of the remarkable milestones in the process of PCB fabrication is the advent of laser systems. Because PCB fabrication is a messy procedure, dealing with a lot of chemicals and materials, milling PCBs to certain sizes and designs mechanically using regular CNC technology has been known to produce a lot of hazardous debris that is detrimental to human health and is known to damage components on those boards.

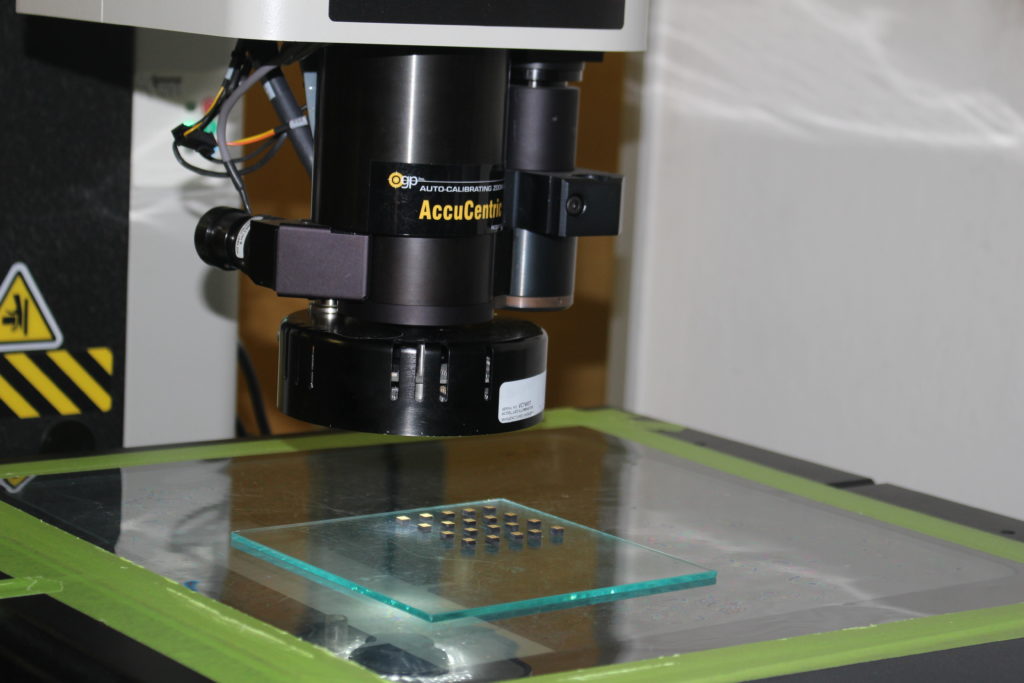

Laser technology has taken PCB fabrication to the next level where precision laser cuts can depanel PCBs cleanly without leaving any residue or producing any debris.

With the ease of incorporating ESD safety measures and the vibration / debris free work environment, laser depaneling is the absolute answer to the increased intricacy and fragility of modern day electronic components.