Laser Cutting vs Die Cutting for Thin Battery Films

For cutting EV thin films there is a debate on die-cut vs laser cut as these technologies differ greatly from the other. Each method provides positive benefits to using but also encompass challenges unique to the technology. Growth in the EV battery industry are continuing to be made and making new advancements such as the thin film battery technology, the options are open. Battery technology is an industry in great demand and is revolutionizing how many of our devices are powered. The industry is continuously researching and developing new ways to create batteries with increased efficiency and power. One aspect of lithium batteries is those designated as thin film solid state batteries. These are flexible and store great amounts of power and are very safe. Thin film solid-state batteries contain solid electrolytes instead of liquid electrolytes that are constructed in layers. The solid polymer electrolyte and simplified separator material improves performance and gives the battery flexibility. It is this flexibility that is allowing the design of devices to become smaller, thinner and be used in applications with greater device usage and customer satisfaction. The complexity of thin film Li-ion batteries requires that materials be processed accurately by manufacturing methods that can adjust to industry requirements. Let’s review what kinds of materials are being processed and how die-cutting and laser cutting approaches these challenges.

Li-ion Materials-What Is Being Cut and How?

In the manufacturing of thin-film Li-ion batteries, both die-cutting and laser cutting methods are employed to process various materials. Each method has distinct advantages and challenges in handling the delicate and precise components of these batteries. Here is a summary of each method:

Die-cutting: Involves using a custom-made die to punch or cut shapes from thin, flexible materials.

- Electrode Films (Anode and Cathode): These are perhaps the most critical materials used in Li-ion batteries.

- Anode material: Can be a graphite or silicon-based active material coated on this copper foil, called a collector.

- Cathode material: Commonly lithium cobalt oxide, lithium iron phosphate, or nickel-manganese-cobalt (NMC) active material coated on an aluminum current collector (thin aluminum foil).

- Separators: Separators can be made from porous polymer films (e.g., polyethylene, polypropylene). The purpose is to electrically isolate the anode and cathode while allowing ion transport.

- Current Collectors (bare foil): Thin copper and aluminum foils before the active material coating, for specific sections or tabs.

- Gaskets and Insulators: For electrical insulation, thermal management, and sealing within the battery pack, thin films of flame-resistant PETs, polyamides, foams, rubbers).

- Adhesive Tapes and Films: Die-cut adhesive components for bonding cells and modules, and for EMI/RFI shielding.

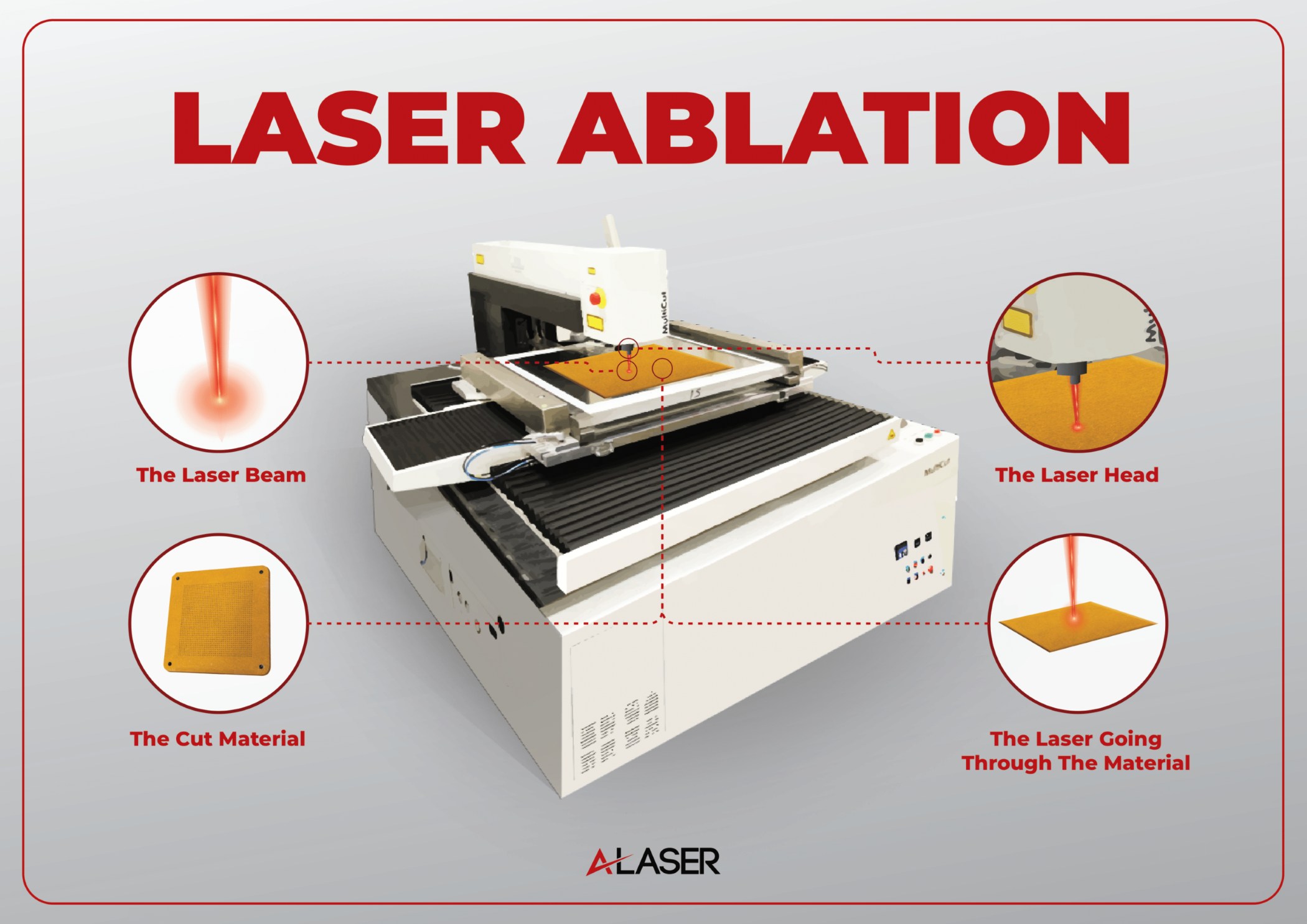

Laser Cutting: Uses a focused laser beam to cut materials.

- Electrode Films (Anode and Cathode): Increasingly used for cutting active material coated foils. This includes:

- Graphite-coated copper anodes.

- Lithium iron phosphate (LFP), LiNiMnCoO2 (LNMC) coated aluminum cathodes.

- Separators: Polymer films used for electrical isolation, such as polyimides.

- Current Collectors (bare foil): Thin copper and aluminum foils, particularly for intricate tab cutting.

- Solid Electrolytes: Especially in the development of solid-state batteries, laser cutting is being investigated for sulfide-based solid electrolyte separators and other solid electrolyte materials.

- Pure Lithium Metal Foils: For advanced battery designs, laser cutting is used for anodes made of pure lithium metal.

- Various Metal alloys and Polymer Components: For precise cutting of battery components, including housing materials or internal structural elements.

The options of materials being processed by laser cutting and die-cutting is a sampling and can cross over to being processed by each technology. Not all materials are listed as new ways to harness conductive and non-conductive materials are being developed. The manufacturing processes for die-cutting and laser cutting, however, stay much the same with adjustments made to customize any precision components. The table below indicates the benefits of using die-cutting and laser cutting, and includes challenges that each has:

| Benefits | Die-Cutting | Laser Cutting |

|---|---|---|

| Speed | Initial work will need die created. Rapid speed for production. | Rapid R&D and prototyping. Supports volume production, but slower than die-cut. |

| Precision | It depends on material and tool die quality but can be +/- 0.0762mm to 0.127mm. | Material dependent but can hold tolerances of +/- 0.254mm, or tighter. |

| Cost | Upfront die costs. Lower per unit cost for production. | No tooling costs, but laser processing higher. |

| Versatility | Good for simple shapes. | Good for simple and complex shapes. Iterations for R&D not a problem. |

| Quality | Clean cuts- with die maintenance. Feature wall edges may get compressed. | Higher quality of features, clean straight walls. |

| Challenges |

||

| Tooling Cost | Tooling cost varies on complexity and material made from. Changes can be expensive. | No tooling costs. Laser parameters can add cost initially for product development. Cbange minimal to no cost. |

| Tool Wear | Dies wear out and need changing to ensure quality level. | No tooling to wear. Maintenance of laser optics scheduled. |

| Material Stress | Deformation of cut edges from die or process. Old tool dies will result in poor edge quality. | Non-contact method, however, HAZ (heat affected zone) can occur on some metal alloys. |

| Contamination | Debris from mechanical cutting. Needs process to keep clean. | Slag or burrs on cutting some metal alloys. |

| Flexibility | Low flexibility for design changes. | High flexibility for design changes. |

| Material Capability | Best for flexible non-abrasive materials. | Best at many materials, metal alloys, polymers, rubbers. |

| Quality Control | Risk of burrs and fragments from poor dies. | Risk of thermal damage to sensitive materials. Laser parameters need to be checked. |

The table is an indication of some of the benefits and challenges found when using die-cutting or laser cutting manufacturing. It does not show all the factors involved when manufacturing development work or high volumes of components, but it can be a guide to use when inquiring into professionals on how they would process your EV project.

In summary, both die-cutting and laser cutting offer distinct advantages and challenges when manufacturing thin film materials for EV batteries. Die-cutting shines in its ability to handle flexible, non-abrasive materials efficiently at scale, though it carries risks of burrs or fragments from suboptimal die quality. On the other hand, laser cutting excels with versatility across diverse materials, including metal alloys and polymers, but requires precision in laser parameters to avoid thermal damage. Choosing the right method depends on the specific requirements of your EV project, such as material type, design complexity, and production volume. Collaborating with experienced manufacturing professionals ensures that these methods are optimized to meet the stringent demands of EV battery component production while balancing quality, precision, and scalability.