Laser cutting EV batteries for precision busbars, insulators, spacers and other components surely is a result from over a hundred years of battery evolution. From Alessandro Volta’s rudimentary “voltaic pile” in 1800 to the rechargeable lead-acid battery pioneered by Gaston Planté in 1859, and the subsequent advancements in nickel-cadmium, nickel-metal hydride, and particularly lithium-ion technologies, the evolution of battery technology has mirrored humanity’s increasing demand for portable power. Remember not too far in the past that handheld flashlights required six to eight D cell batteries to light up the dark. Carrying these was a workout, while today, with lithium power and advancements in LED’s, head worn lights give many hours of even brighter light and weigh just a few ounces. Early electric vehicles and trains, like Robert Davidson’s 1837 electric locomotive or William Morrison’s 1888 electric carriage, demonstrated the potential of

battery power long before the dominance of internal combustion engines. While early 20th-century mass production of gasoline cars temporarily overshadowed electric alternatives, a renewed focus on environmental sustainability has thrust battery technology back into the spotlight. Today, the urgent need to decarbonize transportation—driving, the rapid adoption of electric vehicles (EVs) and the resurgence of battery-powered trains and other modes of transit, underscores the critical role of advanced battery solutions. This escalating demand has placed immense pressure on manufacturing processes, highlighting the necessity for unparalleled precision, efficiency, and scalability. Prototyping of new and clever ways to harness and make efficient use of portable energy cells in providing new solutions to challenges. Consequently, sophisticated techniques like laser cutting have emerged as indispensable for fabricating intricate EV battery components, offering superior quality and speed in this critical stage of the green energy revolution. This introduction paves the way for a detailed exploration of EV battery component manufacturing, delving into the specific materials cut by lasers and the diverse laser cutting methodologies employed to meet the rigorous demands of the electric vehicle industry.

Materials and Laser Technology-Cutting Edge of Progress

In laser cutting for electric vehicles, batteries are a key focus. Most laser manufactured parts will be primarily flat 2D profiles and used to form part of the energy storage devices. Other lasers systems and uses support in cleaning battery component surfaces prior to welding and used for etching of manufacturing information for traceability. For this discussion on laser cutting, the information will focus on the laser cutting aspect that brings with it capabilities of tight tolerances, quality and repeatability. Precision is paramount as any non-conformance could not only mean a malfunction but could lead to a serious public safety issue. The reliability of laser cutting technology has been a positive factor for OEMs in the development and mass production of batteries for EV use. What materials being used in batteries depends on cell technology and each manufacturer has their own recipes for energy storage. The following list is some of the more prominent materials being used for EV batteries:

- Lithium: As the name suggests, lithium is fundamental. It’s lightweight and has excellent electrochemical properties, making it ideal for storing energy.

- Nickel: Another critical cathode material, nickel is known for its high energy density,

- Aluminum: Used as a foil, potential uses for conductivity.

- Copper: As a foil, With great electrical conductivity for electrodes, wiring, heat shields.

- PEEK: PEEK is a non-metallic and versatile material, that is readily laser cut.

- Graphite: It effectively holds lithium ions during the charging process, both natural and synthetic graphite are used.

- Steel: has countless uses worldwide and for batteries, has good structural strength support of device enclosures, keeps devices safe.

As new material formulations are tested and made available for manufacturing, laser cutting systems will be able to support in the manufacturing of new designs.

Advanced Manufacturing with Fiber and Ultraviolet Lasers

The laser cutting community employs different types of cutting machines with each having a significant role for use, especially for cutting certain types of materials. An example of this is the cutting of clear plastics like acrylic, paper based and wood-based materials, which you would observe CO2 lasers being used. For ultra-thin materials, in the thickness of 3-10microns, perhaps a femtosecond or picosecond system would be the choice. Laser cutting for EV vehicles, on the other hand, has found for many applications, two laser types being used most readily such as fiber and ultraviolet technology. Here is the breakdown of these two laser types:

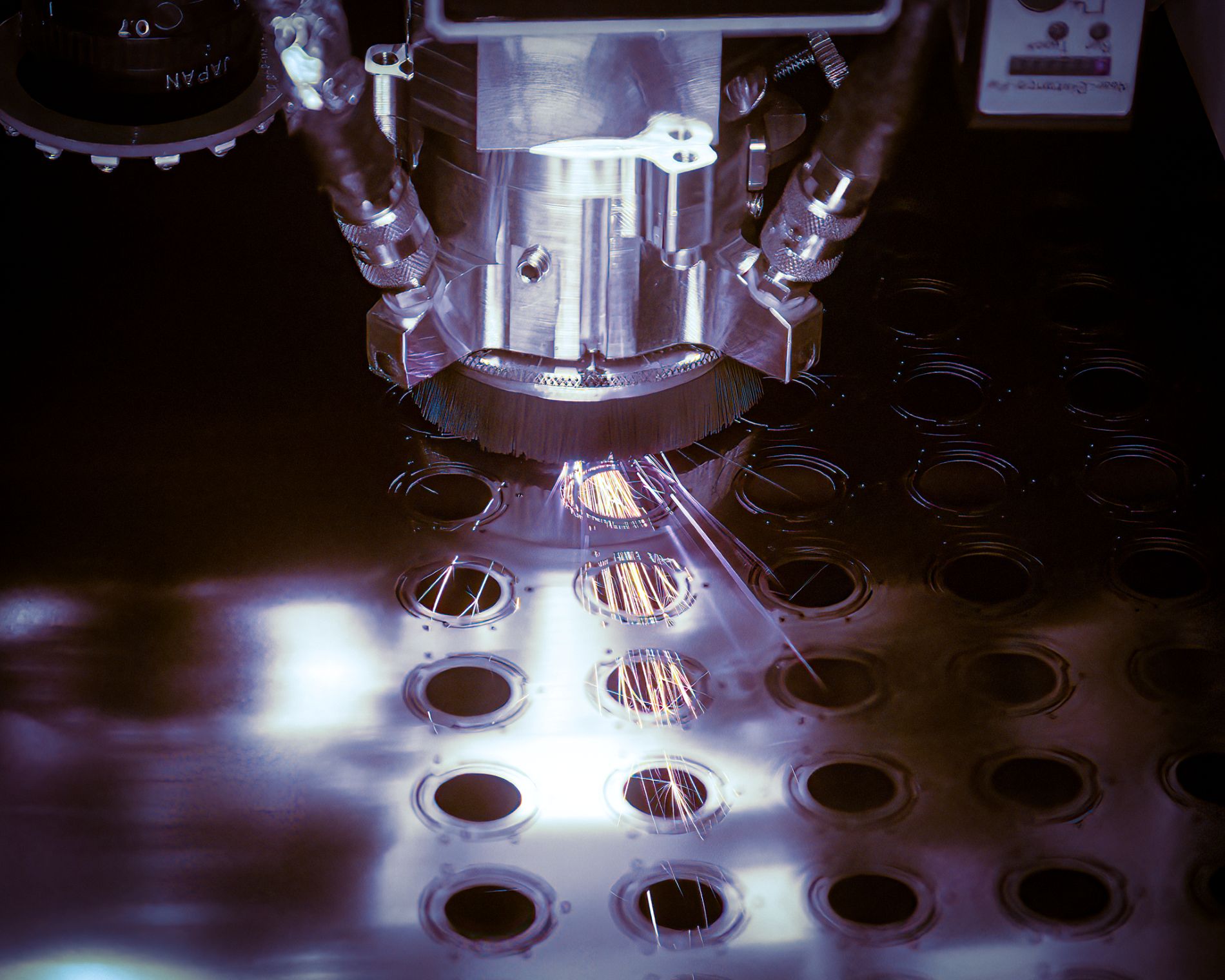

Fiber Lasers: Having more power (wattage) than most other laser types, fibers lasers are cutting a host of materials, including steel, copper, nickel, and aluminum, but also tungsten, titanium, brass and others. The capability of fiber lasers to cut thicker gauges of metal alloys from about 0.254mm up to 4mmm thick or greater, opens the opportunities for many industries while holding a tolerance of +/- 0.0254 mm to 0.0762 mm. Made with different power levels from 50 watts to 4000 watts of higher, fiber cutting technology rapidly cuts through some of the more challenging reflective metal alloys.

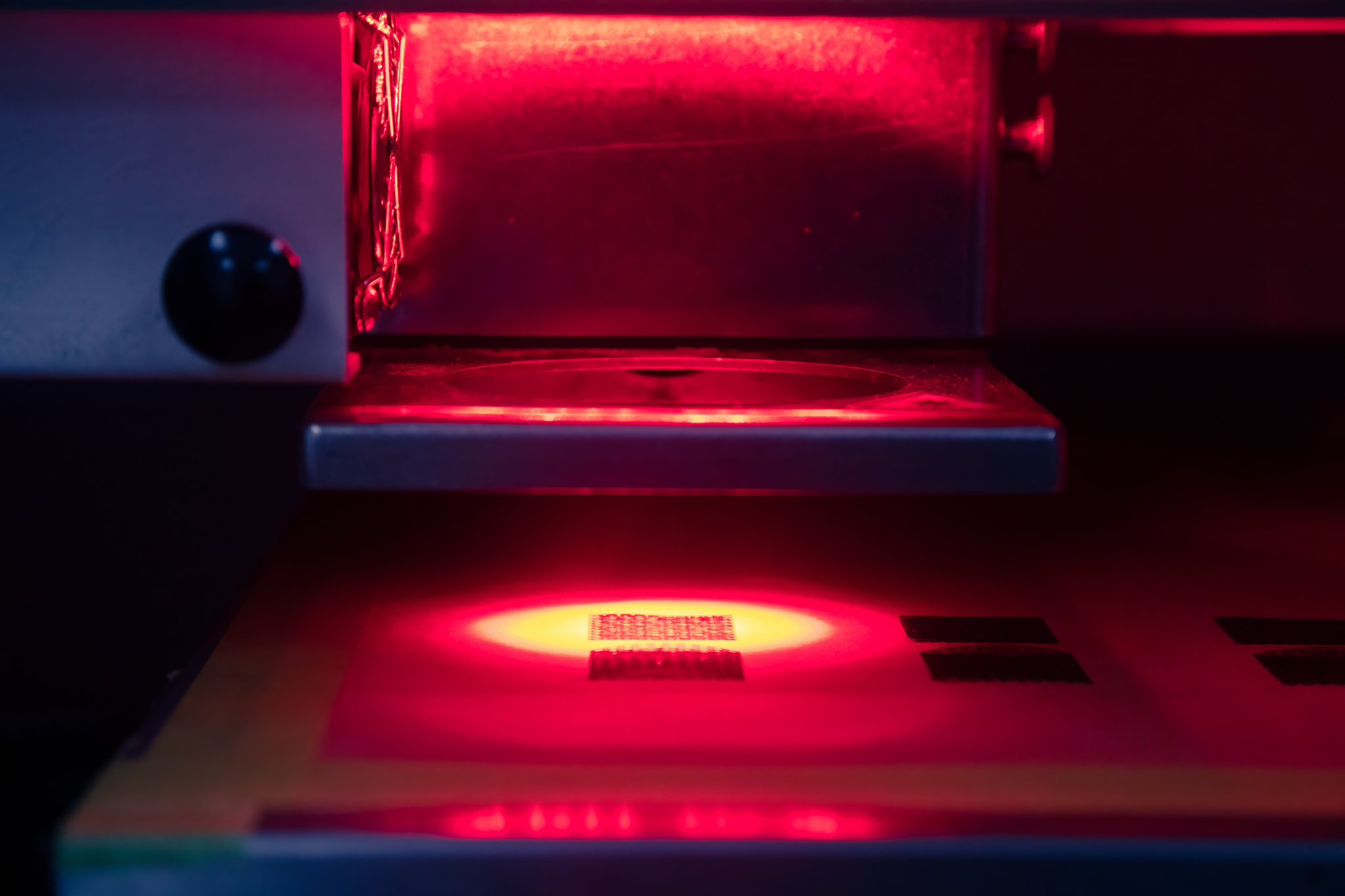

Ultraviolet Lasers: Versatility is the word that is synonymous with UV laser cutting machines. This technology is being used for the EV battery industry to cut many of the same metals alloys that a fiber laser cuts, but in much thinner rolls and sheets. UV lasers are pulsed laser systems, using relatively low power such as 15 to 50 watts for many systems as compared to fiber lasers. With small beam diameters for example at 20 microns, UV cuts of copper or nickel, will have very tight radius and straight walls. This is done with tolerances of +/- 0.0127 mm to 0.0254 mm for many projects. Additionally, UV lasers cut non-metallics including polyimides, rubbers like nitrile and silicon, and adhesives that are acrylic and silicon based.

The Laser Process-From Prototype to Production

Laser cutting for electric vehicles does not begin immediately with production orders, rather in most cases an inquiry into the laser process and materials capabilities comes first. The materials mentioned above can take some time to procure as each manufacturer can have special formulations made and proprietary materials combined that are required for their devices. Knowing how the laser process will affect the materials edge quality, surface roughness, heat affected zones, are important to review. Through R&D and prototyping using laser technology has become a great advantage to developing precision components for EV technology and many other industries. While going through this rapid pace of iterations and testing, the reliability and throughput of the laser process in formed. Listed below are some of the benefits of why EV development has partnered with laser cutting services:

- Rapid Prototyping: Without the need for custom dies, fixtures or extensive set-up, laser cutting materials into prototypes can provide components and data for review much quicker than other methods.

- Materials flexibility: From materials used for EV development to those used for medical devices, optics, wireless communication, PCB assembly, aerospace and so many other industries, the capabilities of laser cutting supports many companies with development of new technologies.

- Volume Production Support: Moving from prototyping to volume manufacturing means all the requirements have been met, and for laser cutting EV batteries, this is a giant plus. Throughout the R&D and prototype phase, the laser cutting service providers will know the best process to proceed in any ramp up for demand of products.

- Tight Tolerance Manufacturing: A great characteristic of laser technology is the ability to cut materials, both metallic and non-metallic, with a high degree of precision. Many of the systems used in cutting EV battery components hold a standard tolerance of +/- 0.0254mm and some projects and designs are held at +/- 0.0127mm.

Being part of the supply chain is a large part of any manufacturing service and laser cutting, with its foundation of tight tolerances and repeatable cut profiles had become a solid contributor to EV batteries. The systems being utilized for these complex parts will be highlighted in the following section.

Laser cut battery insulation, battery connectors or other components used in EV batteries, have a significant edge when manufactured with laser technology. The versatility of these machines cuts down the time for R&D and testing of prototypes and can support volume production once demand increases. The cost saving of not needing expensive dies or tooling used by other manufacturing methods is a great plus when considering options to EV components. Considering the delicate and complex substrates of materials and geometry that demand precision, laser cutting for electric vehicles has become part of a select group of manufacturing specialists in the supply chain and has the versatility to adjust as changes to EV technology take place.