Laser Cutting Solutions for High-Precision Shims Kapton, Stainless Steel, & More

A-Laser specializes in providing advanced laser cutting solutions for high-precision shims in a variety of materials, including Kapton, Stainless Steel, SOMABLACK, and Grafoil. Our cutting-edge technology and expertise make these materials well-suited for critical applications in industries such as aerospace and medical devices.

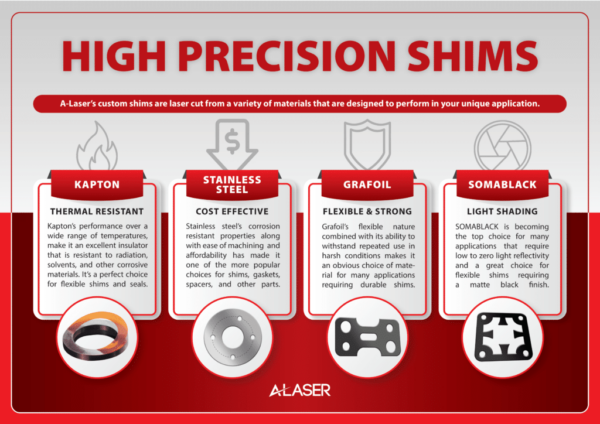

Popular Materials for High Precision Shims

Kapton, a polyimide film, is renowned for its exceptional thermal, electrical, and mechanical properties, making it ideal for a variety of industries. With our advanced laser cutting capabilities, we can create shims with intricate designs in Kapton, ensuring precise dimensions and smooth edges. These high-precision Kapton shims offer reliable performance in critical applications where thermal stability and electrical insulation are paramount, such as in aerospace components and medical devices.

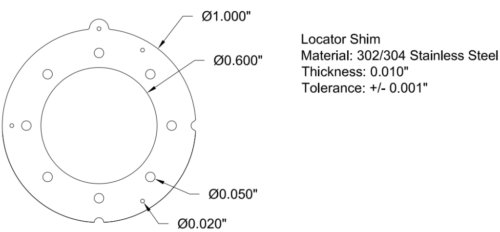

Stainless Steel, known for its durability and corrosion resistance, is widely used in aerospace and medical device industries. Our advanced laser cutting technology allows us to cut Stainless Steel shims with micron-level precision, resulting in tight tolerances and smooth edges. Stainless Steel shims provide excellent mechanical strength and dimensional stability, making them ideal for precision applications in aerospace components, surgical instruments, and medical equipment.

SOMABLACK, an ultra-black material with exceptional light absorption properties, is critical in optical systems. Our precision laser cutting capabilities enable us to create shims with intricate shapes and contours in SOMABLACK, ensuring precise dimensions and clean edges. These high-precision SOMABLACK shims provide unmatched performance in minimizing stray light and improving signal-to-noise ratios in aerospace instruments, optical sensors, and medical imaging devices.

Request a Quote for Shims

What to Expect When Working with A-Laser

- Precision: Our UV laser processing delivers clean and precise edges, ensuring accuracy and reliability in your applications.

- Efficiency: Our advanced technology allows for fast and efficient laser cutting of shims, reducing production time and costs.

- Flexibility: We can accommodate a wide range of sizes, patterns, and shapes, offering customized solutions to suit your specific requirements.

- Quality: We adhere to strict quality standards and perform thorough inspections to ensure that our laser-cut shims meet your specifications.

- Expertise: Our experienced team of engineers and technicians are knowledgeable in materials and design and can provide expert guidance and support throughout the project.

Partnering with A-Laser for high-precision shim cutting means leveraging our cutting-edge technology, expertise, and commitment to quality. Our team of experts collaborates closely with customers to understand their unique requirements and provide customized solutions that meet the highest standards of precision and performance.