Laser Cut Polyester Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Weaving Through Industry

Laser cut polyester film produces intricate details achieved by a focused beam of light. Smooth and versatile, polyester films like Mylar or PET are one of the factors why industries use laser cutting. This marriage of material and technology opens a world of possibilities, transforming these seemingly simple materials into extraordinary creations. Polyester laser cut components provide crucial precision and durability for a wide range of industry uses. The early history of this synthetic material goes back almost 100 years ago when polyester was discovered but not fully developed. The focus on another material, called nylon, had resources directed to its formulation and it would be until late 1930’s and 1940’s that polyester would be fully developed and then introduced to the public around 1951. Polyester is a synthetic fiber derived from coal, air, water, and petroleum. By a process called polymerization, chemical reactions between an acid and alcohol combine two or more molecules to create a large, strong, and stable molecule.

Today Polyester is the third most-produced plastic material in the world and is used extensively in clothing and fabrics. Early in manufacturing polyester was demonstrated as a change to the modern world through the 1950’s and 1960’s, as it gained popularity as a material for clothing, upholstery and other textiles with polyester fibers and yarn spun into various fabrics. As a fabric, polyester is not biodegradable, but has great color fastness, meaning it will not fade readily in sunlight. It is durable and resistant to stretching, giving it a long functioning life. For industrial uses, polyester has great benefits and applications of precision components, much unseen by a majority of the public, but well known to the industries it serves.

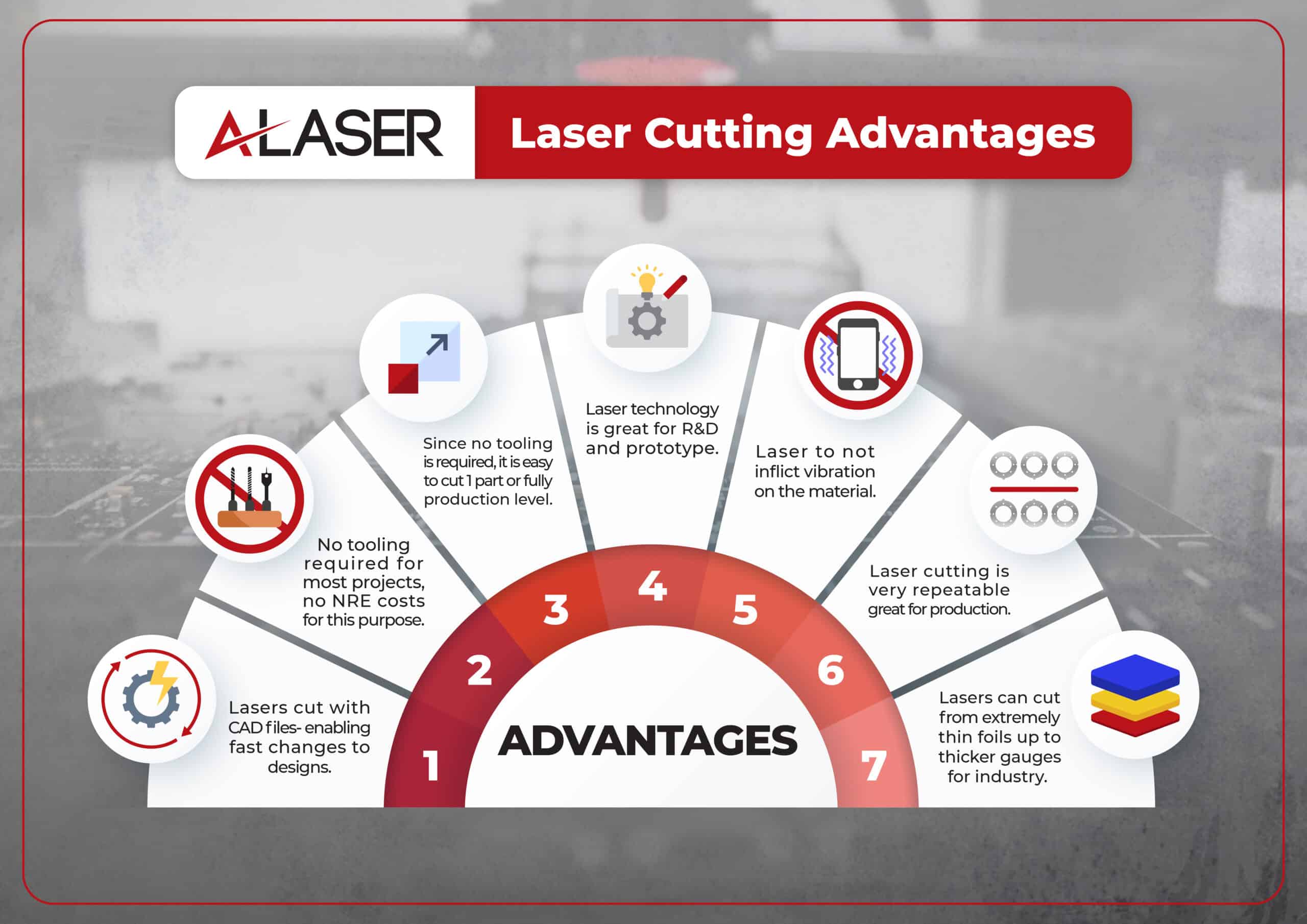

Laser Technology and Polyester

Besides being made into fabrics, polyester is made into films and sheets that are processed by laser technology for precise cut geometries supporting vital sectors of industries. A common name for this type of polyester is Mylar. Mylar is a trademark of Dupont Tejjin Films. Often this type of polyester film is grouped together with other mylar variants and called mylar. Mylar is made as a clear or colored film or can be made as metallized and have coloration to the formulation, which a mylar balloon is a good example of this. Laser technology is well known for its contributions to medical care both for treatments of the skin, surgery and treatment of the eye, but has proven its place amongst manufactures and many sectors of consumer products and commercial sectors. Known for providing intricate and accurate components, lasers play a major role in cutting polyester materials like Mylar or PET for many industries and applications such as shims, spacers and gas and moisture barriers. Lasers use different wavelengths of light and the two that are used most widely in cutting polyester applications are ultraviolet and CO2 systems. Ultraviolet lasers, commonly referred to as UV, are versatile machines that can cut a wide range of materials from plastics like polyester to metal foils. CO2 lasers are known for their ability to cut thicker plastics, wood and paper, with high powered systems cutting metal alloys. However, there are some key differences between the two laser systems as shown in the table below:

| Laser System | Core Technology | Materials Cut | Advantages/Disadvantages |

|---|---|---|---|

| Ultraviolet (UV) | Ultraviolet wavelength- small beam diameter of 20um(micron). Accuracy up to +/- 0.0127mm. | Polyester, FR4, polyimides, PEEK, metal foils, rubber materials, graphene materials. | Strength is cutting of thin gauges of plastics and metals. Many systems positional tolerance +/- 0.0508mm over 500mm. Thicker materials not recommended. |

| CO2 | CO2 gas- beam diameter of 0.025mm to 0.25mm. Tolerance of +/- 0.050mm to 0.125mm, depending on system. | Polyester, Acrylic, wood, paper. | Cuts many plastics at thickness greater than UV systems. Also good for laser etching and marking. |

UV and CO2 lasers both have capabilities that give the best quality and reliable parts from the technology harnessed by each. Choosing what laser system to manufacture a polyester component will depend on the design factors of such components and steer to the best available laser option.

How Is Polyester Used in Industry?

Wearing a garment or using a product like a backpack made of polyester is an easy demonstration of the use of this synthetic material. It is incredible to see the quantity of products using some percentage of polyester in the goods we buy by reading the labels. However, for many devices and applications beyond consumer goods, polyester is concealed, but vital to how the supported devices and systems function. As mentioned earlier, polyester or Mylar, is the type used most in industrial applications, for its resistance to moisture, electrical insulating properties, resistance to chemicals, heat and puncture resistance. Other variants of polyester like Mylar are PET, PETG, and PBT. Materials such as these can be formulated with glass fibers and minerals to reinforce their durability and strength. These characteristics are important in systems that polyester films parts serve, but remain utterly invisible to the public, unlike polyester garments and textiles. The uses of Mylar, PET and other polyester based films and tapes are fascinating and can be found being used in the following ways:

- Aerospace: Engine parts, requiring high temperature resistance and dimensional stability (though often used in conjunction with other materials). Thermal blankets, insultation.

- Spacecraft components: Certain components in satellites and other spacecraft, requiring lightweight materials with good electrical insulating properties.

- Horticulture: Reflective Mylar is used for indoor growing to enhance the efficiency of the lights.

- Electronics: Electrical Insulation is used in printed circuit boards, in capacitors as insulation barriers and for other electronic components. High dielectric properties are used to protect wires.

- Food Industry: Because polyester films like Mylar have great tensile strength, it provides a strong and reliable packaging source. It also is use as a moisture barrier and resistant to heat.

- Solar Panel Manufacturing: Used as a barrier from chemicals and moisture and for UV protection against the SUN, that would rapidly degrade solar panels, if not protected.

- Medical Industry: Some specialized implants may utilize polyester components, though typically in combination with other materials. Drug delivery systems in drug delivery devices, such as pumps and reservoirs.

Emerging Precision Components from Polyester

- Microfluidics: Polyester-based materials are being explored for use in microfluidic channels and components due to their biocompatibility and ease of fabrication.

- MEMS (Microelectromechanical Systems: Polyester-based materials are being explored for use in certain MEMS components due to their potential for low-cost fabrication and integration with other materials.

Important Considerations:

- Material Combinations: In many critical applications, polyester is often used in combination with other materials, such as metals, ceramics, or other polymers, to achieve the desired performance and characteristics.

The Laser Cutting Intrigue

Considering how laser cutting can revolutionize your next project, whether it’s crafting intricate artwork, developing innovative packaging solutions, or prototyping new products, using polyester based materials will provide high quality and precision. Many laser cutting services offer prototyping and small-scale production runs, allowing you to experience the transformative power of this technology. When Mylar, PET or other polymers are laser cut, these components support the changing manufacturing world, ever striving to take ideas into physical form. Let laser cutting unleash the full potential of polyester films and unlock a world of creative possibilities for your project.