Laser Cut Noryl Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Laser cut Noryl will offer many advantages over components produced by other methods. Noryl is a trademark of SABIC corporation and is thermoplastic of polyphenylene oxide (PPO) or polyphenylene ether (PPE) resins with polystyrene. It is known for a balance of properties that include dimensional stability for very low moisture absorption and low thermal expansion with good heat resistant. Noryl’s thermal stability and with a high dielectric and insulating properties are excellent for high voltage and high frequency applications. Fabricating precision flat parts out of Noryl requires methods keen on handling plastics as well as controlling a process to ensure the highest quality and this is where laser cutting technology has become a proven supplier of Noryl parts. For additional information about laser technology in processing Noryl, please review the following questions and answers.

More Than One Method

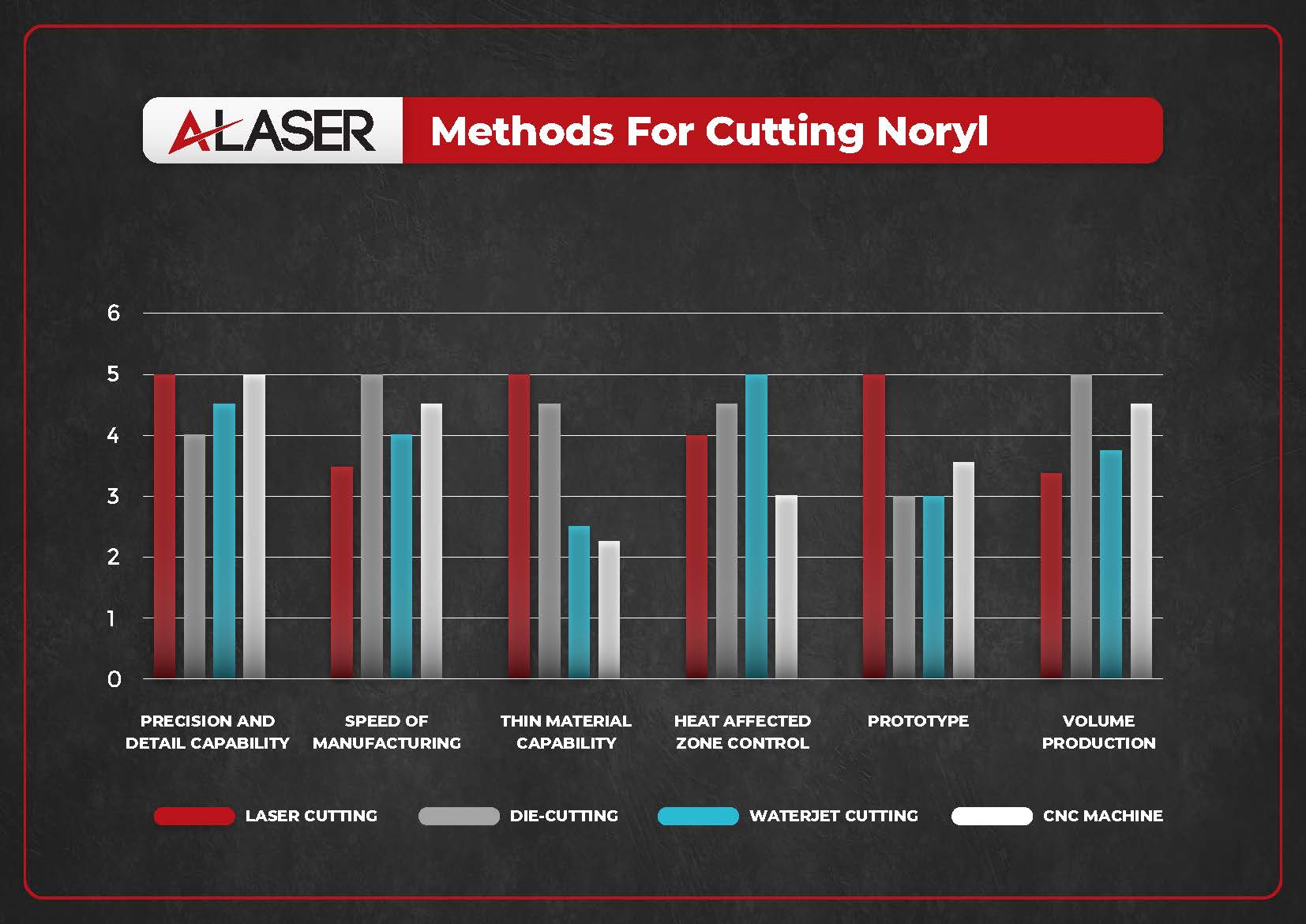

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Noryl?

Comparing one manufacturing method over another is not an exact measurement of capabilities since project details dictate the variables applied. However, for a sense of how Noryl sheets can made into precision parts using different methods, the following table is a general guide.

The Precision of Laser Technology

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Noryl?

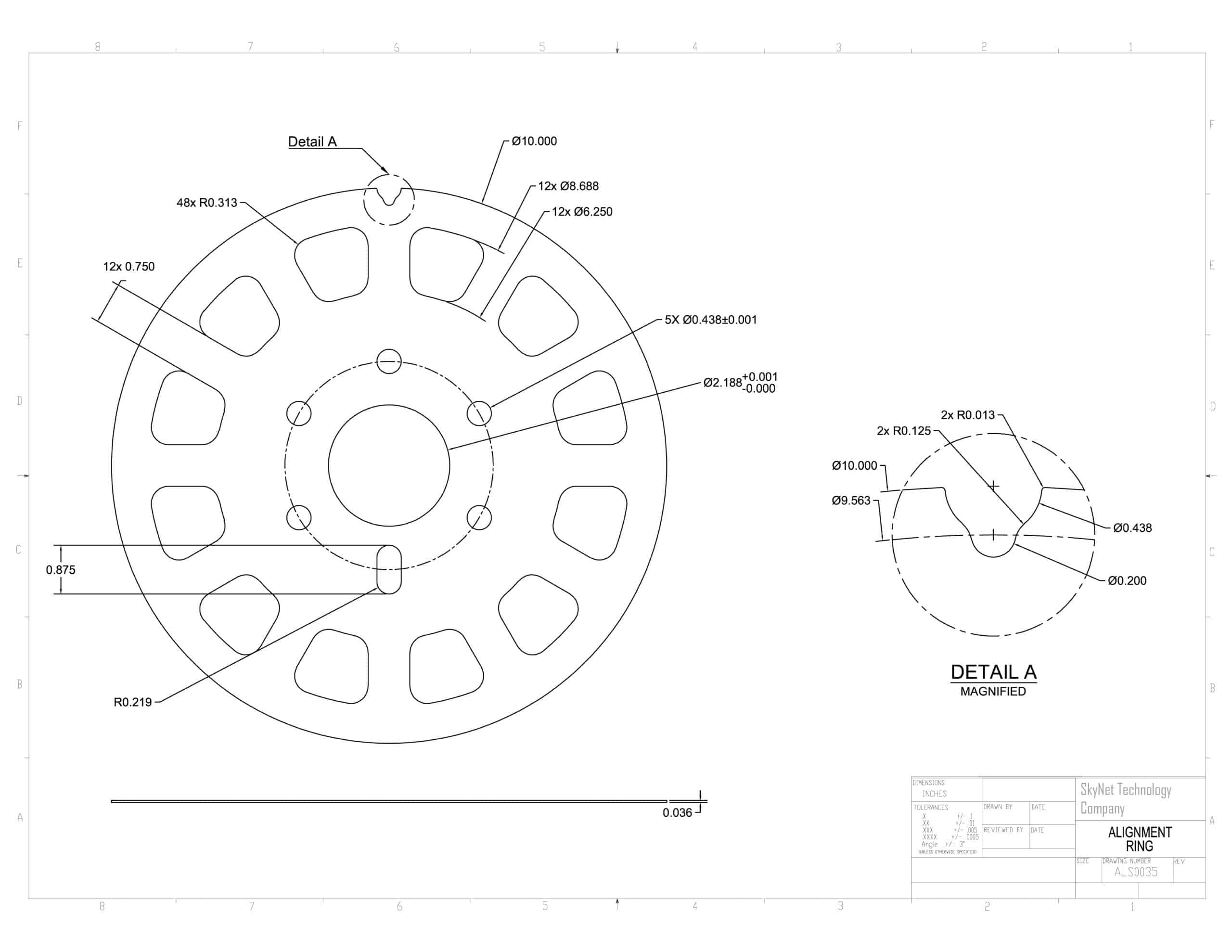

We can maintain tight tolerances of +/- 1mil to +/- 2mils for many projects using Noryl. Our advanced laser systems and process control techniques ensure precision and repeatability, delivering high-quality, accurate parts every time. What this means for your project is that Noryl parts will fit perfectly into assemblies, whether they are enclosures for electronics, internal mechanical components, or specialized brackets. This level of precision allows us to cut intricate shapes, fine features, and small holes that are impossible to achieve with less accurate methods, opening up new design possibilities.

Balancing Materials

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Noryl?

When cutting Noryl, its material traits quietly shape the final edge and precision. Because it is a low-reflective plastic, lasers interact efficiently without the issues seen in shiny metals, ensuring clean, consistent cuts. Its relative softness means the edges don’t chip or fracture, though this same softness requires careful tuning of laser parameters to avoid slight melting at the kerf. With low thermal conductivity, heat doesn’t spread quickly through the material, so the laser’s energy stays concentrated at the cut zone. This too is a factor controlled to avoid HAZ (heat affected zone). Being aware of Noryl’s characteristics results in delivering sharp detail. Together, these characteristics make Noryl generally forgiving under the laser, with fine tolerances achievable when the process is carefully balanced.

Edge Quality Expectations

What Edge Quality Can Be Expected When Laser Cutting Noryl? Are Burrs or Heat-Affected Zones (HAZ) Present?

Laser cutting plastics can assist with advancing technologies with new designs, that other manufacturing techniques cannot produce. Since plastics and polymers in general vary greatly in their chemical properties, each will have factors that influence the overall edge quality. Laser specialists fine tune parameters such as laser power, speed, and wavelength to optimize quality. With this controlled processing of Noryl, you can expect the following of edge quality:

- Smooth, clean edges are typical, thanks to Noryl’s low reflectivity and good laser absorption.

- Minimal burrs form, as the material melts cleanly rather than fracturing.

- Slight melting or glossiness may appear along the cut edge, especially at higher power settings.

- Heat-Affected Zone (HAZ) is generally small due to Noryl’s low thermal conductivity, but localized softening or slight discoloration can occur.

- Tight tolerances are achievable with well-controlled laser parameters.

Key Takeaways

What Are the Benefits of Laser Cutting Noryl?

Noryl and similar plastics are used for many applications requiring strength, durability, and chemical resistance for numerous applications in automotive, aerospace, medical device, electronics and many more high-profile industries. However, manufacturing parts made out of Noryl can be quite challenging for any manufacturing method, but laser technology is one that has developed processes by using Ultraviolet and CO2 laser technology.

Laser cutting machines are extremely accurate and very reliable resulting in high edge quality. Components made using laser cutting support prototypes and high-volume manufacturing. Projects with startups or established OEMs, scientific research can be confident that the laser cutting machines will produce highly accurate flat 2D components that in many cases surpass other manufacturing methods.