Laser Cut Dry Film Adhesive Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Laser cutting technologies offer a range of unique qualities and capabilities, including reliable precision and the versatility to cut various material types. Among these materials, dry film adhesive stands out for its specialized properties and applications. Dry film adhesive is typically composed of thermoplastics or thermoset materials and are supplied as a solid, non-tacky film or mesh. The adhesive is activated by either heat or a solvent, which transforms it into a bonding agent suitable for numerous uses.

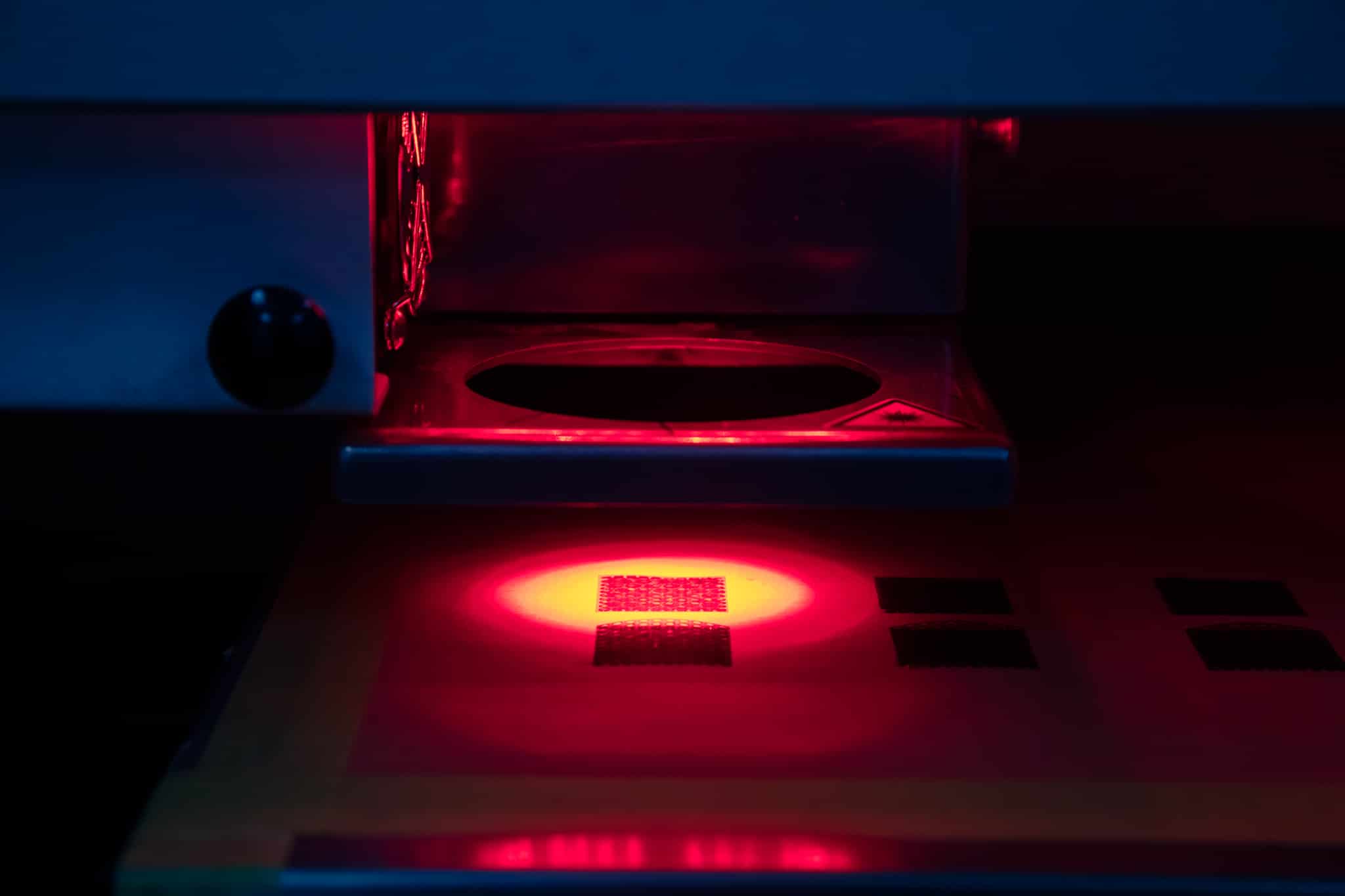

UV Laser Cutting Process

When dry film adhesive is processed using UV laser cutting, the laser’s short wavelength and high photon energy facilitate material cutting through a process called ablation. Precise control of laser parameters is essential to minimize distortion and prevent the formation of a heat affected zone (HAZ), ensuring the production of flat, high-quality components. Components manufactured from dry film adhesive using laser cutting are widely used in industries such as electronics, aerospace, and automotive. Typical applications include heatsink attachment, die attachment, and many other specialized uses. With extensive experience in cutting dry film adhesive, A-Laser invites questions regarding the laser cutting process and how best to meet project requirements. For further insight, a series of Q&A is provided below to offer more information about manufacturing dry film adhesive parts with laser technology.

Manufacturing Methods

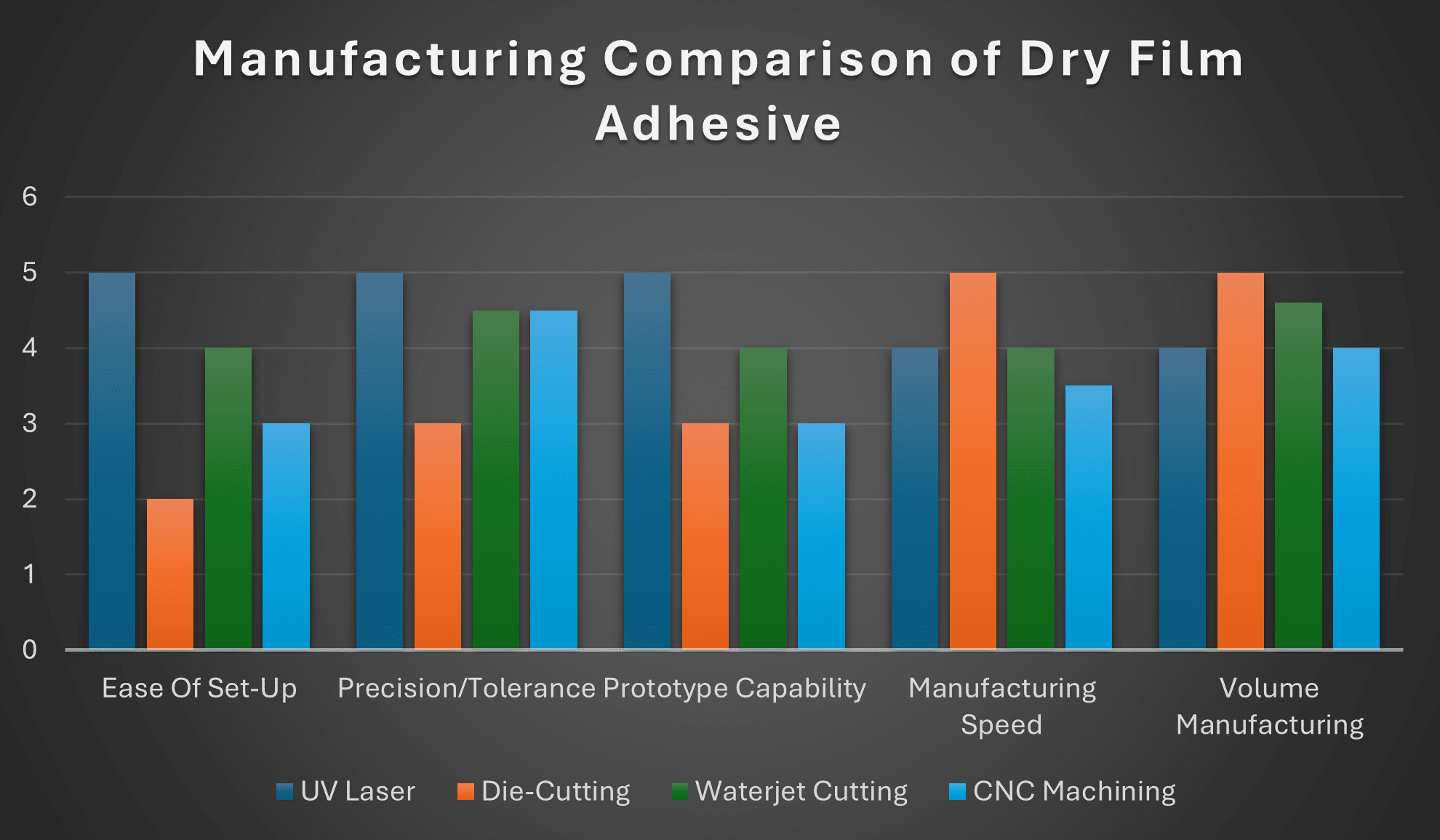

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Dry Film Adhesive?

Laser cutting (specifically UV laser ablation) is often considered the ideal method for cutting intricate patterns in thin dry film adhesives, particularly for high-precision applications like electronics. The following comparative chart outlines how UV Laser Cutting stacks up against traditional methods for processing dry film adhesives:

There can be multiple options available for a precision project and the best decision should be made by weighing the capabilities of each manufacturing method against the project’s requirements. Lead time, cost, and experience of the intended supplier are also key factors. Speaking with qualified services will be your best source of firsthand information and we at A-Laser will be happy to learn more about how we may be of service.

Tolerances We Can Hold

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Dry Film Adhesive?

Laser cutting machines use intensified light energy to form a cutting beam. This beam, although highly accurate in producing fine features, is basically a thermal process. Heat is always a factor to adjust too in maintaining a set tolerance. For UV lasers, this tolerance control is expected in cutting of dry film adhesive to a +/- 1mil to 2mils. With a minimum of discoloration along the cut edge, there is no detrimental effect to the parts geometry or function.

Material Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Dry Film Adhesive?

Dry Film Adhesive cuts very well using ultraviolet laser cutting machines, so its characteristics do not promote issues that affect the overall edge quality and tolerance control. This does not mean that the laser is not adjusted, rather laser parameters that include laser power, laser cut speed, laser focus, laser passes, and the frequency are fine tuned to cut at the optimum quality for dry film adhesive. This procedure produces a “laser tool”, that is unique to each project and material.

HAZ and Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Dry Film Adhesive? Are Burrs or Heat-Affected Zones (HAZ) Present?

Following up on the previous question, with the correct laser parameters set, you can expect with dry film adhesive a uniform cut edge. There may be minimal discoloration or darkening along the cut path but has not shown to adversely affect the tolerance nor function of the components.

Key Takeaways

What Are the Benefits of Laser Cutting Dry Film Adhesive?

Laser cutting, especially UV laser ablation, is highly effective for processing dry film adhesives, offering precise and uniform results. This technique allows for optimal edge quality, minimal adverse effects, and tailored processing for each project.

- Enables intricate and high-precision cuts, ideal for electronics and detailed applications.

- Supports prototype and multiple iterations.

- Produces uniform cut edges with minimal discoloration or darkening

- Maintains tight tolerance control without compromising material function.

- Allows for adjustment of laser parameters to optimize quality for each specific adhesive and project.

- Minimizes heat-affected zones (HAZ) and burr formation, preserving material integrity.