Is Your Project Right for Laser Technology?

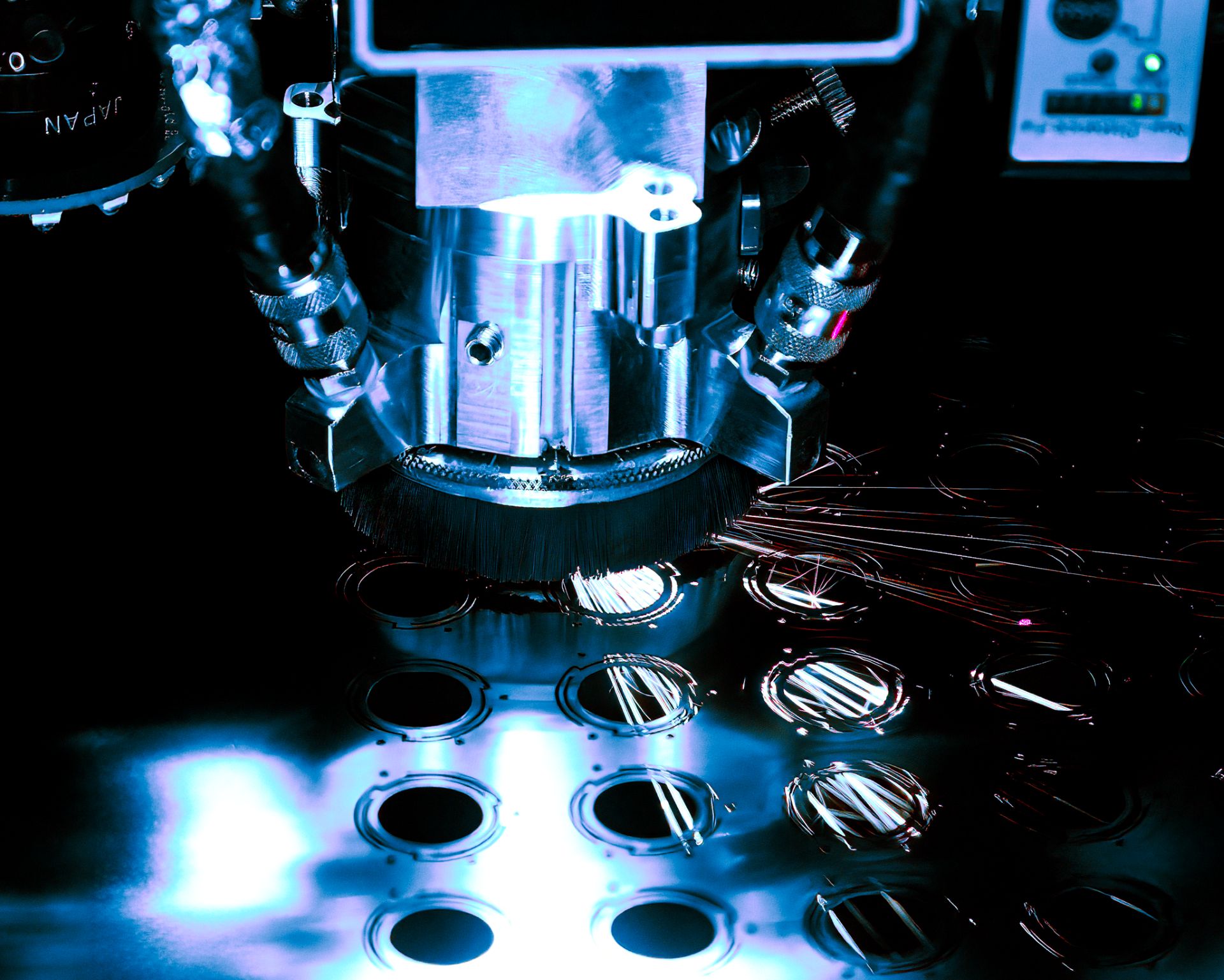

There can be some uncertainty about using laser cutting machines and perhaps some misinformation about how they are utilized for precision manufacturing. With so many projects coming forward that encompass a wide array of materials, design features, and applications, it is easy to understand why there are many questions potential customers have about using laser cutting technology and if it is right for their project. Laser cutting machines are an excellent addition to precision manufacturing and over the past 30 years or so, it’s a wonder how some advancements in medicine, aerospace, communications, and battery technology would have gone forward without the use of lasers. The foundation has been set for laser manufacturing, but there still are many questions about it that I hope to clarify and open the avenues to getting the right projects done with the capabilities of laser cutting machines and manufacturers.

Those Early Questions

A great number of first contact communication begins with “can you cut..?” It is an obvious question and many times the answer is enough to move forward or recommend potential alternative methods. There is an ever-increasing list of materials that lasers do cut, and the list does grow as new projects come forward. To jump start on the materials capabilities for laser cutting, here is a list to review:

Did You Know That Lasers Can Cut:

- Nitinol

- Molybdenum

- Nickel

- Brass

- Polyester

- Graphene

- Nitrile Rubber

- Silicone Rubber

- FR4

- Alumina Ceramic

- Copper

- Stainless Steel

- Tungsten

- PEEK

- Kapton

- Titanium

- Adhesives

- Brazing Alloys

- Paper

- Wood

This list is a sample of many types of materials being cut into precision components for industries from consumer goods to vital defense applications. Material capabilities, however, are just one factor in determining a project’s validity. The design aspects are just as crucial in the determination.

Accurate Profiles

What laser manufacturing is best at is producing flat, 2D parts. There are specialized systems that create intricate medical stents out of tubular metals and non-metallic materials, but laser cutting primarily is best producing flat designs. The simple shape of this type will be a washer with an inner and outer diameter while a complex design may be used to regulate fluidics for a medical diagnostics device. 3D designs or those with multiple dimensions, are better processed by technologies such as CNC machining, waterjet cutting or even 3D printing. The question often asked is to laser service providers is “how accurate is your laser?” Knowing that your profile is best for laser manufacturing leads into why this method excels at these types of parts and it is due to the accuracy, repeatability, and flexibility of the technology. Laser cutting accuracy falls into micro-machining levels that hold tolerances of +/- 0.0076mm to +/- 0.0254, for many systems and broader tolerances of +/- 0.0762mm. All these are exceptional for a process that uses beams of light energy for the ablation of materials. The following table is an overview of laser cutting systems and their capabilities:

| Material Type | Best Laser Type | Thickness Consideration | Post-Processing |

|---|---|---|---|

| Stainless Steel | Fiber Laser | Best for >25 mil | Acid Cleaning if needed |

| Thin Metal Foil | UV or IR Laser | Thin & Delicate | Sanding if required |

| Thick Metal (>25 mil) | Fiber Laser | Thick & Durable | No extra finishing required |

| Thin Non-Metal (<2 mil) | CO₂ Laser | Must be under 2 mil | Ship As-Is or clean with alcohol wipe |

| Acrylic | UV Laser | Any thickness | Alcohol wipe if needed |

| Polymer | UV Laser | Any thickness | Cleaning with alcohol wipe if required |

Types Of Laser Service Providers

Cutting materials accurately is a key factor and maybe all that is needed in concluding that laser cutting is the best method to create the precision component needed. Manufacturers do specialize and focus their expertise based on the laser technology they have. Some will be focused on large scale parts, such as those in size beyond 22”x22” inches. Platforms can be as large as 8’x 16’ feet or larger, and cutting thick steel and aluminum for frames, enclosures and other large scale industrial needs. On the contrary for micro-laser manufacturing the bed size may be as small as 8”x10” inches and cutting the ultra-thin foils and polymers with parts sizes 0.5mmx0.5mm for example. A key aspect of any laser systems is the ability to cut 1 part or be secured for mass production. They can seamlessly address the needs for R&D and prototype support to move into production runs with no tooling costs. Laser cutting is versatile in this way unlike other methods, that require tooling or extensive set-up of cutting tools before manufacturing can begin. The freedom of engineers to submit multiple iterations of a design and not incur additional cost if the material and thickness remain the same, is a big plus.

Start Ups To OEMS

For the progression of technical advancements to take place, there needs to be a conduit for the mechanical ideas to run through. Laser cutting of these flat components is a great method to use by either established OEMs or start-up companies. The flexibility in materials as mentioned earlier and the capabilities to cut a handful of components or take the lead in volume production manufacturing are positive attributes of the laser manufacturing industry. Examples of industries using laser support can be seen in semiconductor manufacturing, space telecom, data security, food processing, textiles, genetic diagnostics, drug delivery systems, oil and gas and so many other industries.

Conclusion

In summary, determining if your project is right for laser technology involves considering several key factors. Laser cutting excels in producing highly accurate and intricate 2D profiles, making it ideal for flat components across various industries. Its flexibility to handle both small-scale and large-scale parts, along with the ability to transition seamlessly from prototypes to mass production without incurring additional tooling costs, offers significant advantages. If your project requires precision, repeatability, and the ability to adapt to different designs without extensive setup, laser technology may very well be the optimal choice. By understanding these capabilities, you can make an informed decision and leverage the benefits of laser cutting for your specific needs.