High Production Volume Manufacturing

What Is High Production Volume?

We receive many inquiries about projects from prospective customers and I am still humbled that many ask if we will cut 1-2 parts? Yes, of course, is my answer and we are happy to support in any way and at any volume within our laser services. High production volume in our service industry means multiple things. To some, a high-volume machining project is a few hundred parts per year, while others a few thousand every few months. While on another level high volume production is in the thousands and hundreds of thousands per year and set in place with a demand schedule, a blanket purchase order and a clear scope of work. A-Laser’s use of experience, knowledge, commitment to quality, and customer service has continued to earn ongoing opportunities as a supplier of laser cut precision parts. Manufacturing, like all business, depends greatly on the influx of orders. The quality produced and the services provided ensure continued patronage from current customers and new opportunities from prospects. Being able to become part of the supply stream is where A-Laser can be a great value as a partner through collaboration. Our high-volume production machining process is supported by a Quality Management System, a customer service team, certification, knowledge, and technology.

A-Laser is structured under a QMS or Quality Management System. All projects, volume or R&D level are subject to have every step in the process confirmed and certified to the project’s requirements. This is done in part by having ISO certification of 9001-2015. A quality manual along with regulations of record keeping of all data, documents, and communication. Additionally, the QMS ensures all manufacturing equipment, tools and other devices are kept calibrated. This is vitally important to customers seeking a provider who will have records on hand for audits.

Customer service is key in our ability to provide the customer with our capabilities and project status but also to relay the project’s goals and review with the production team. Communication is a valuable commodity and is needed for success on every level. We will learn what the potential volume and scope of work is for your project. We ask because we want to focus the support whether it is for R&D or high-volume production. The experience we have acquired over the past 20 years allows selection of the best laser system to use and what laser tool or laser parameters will result is the high-quality cut part expected.

This knowledge of laser manufacturing is complemented by the technology used. Laser systems are terrific methods to cut precision parts, but not one system type can cut every material. To be effective in support of high production volumes a range of laser systems includes ultraviolet, infrared, and fiber laser technologies. This coupled with multiple systems, adds redundancy, and enhances our ability to support production at many levels.

High production volume projects require the members of the supply stream to have flexibility of supporting changing production quantities. Having a QMS in place and experienced professionals ensures every part is the same. This includes ongoing communication with the customer and backed with technical experience and manufacturing redundancy.

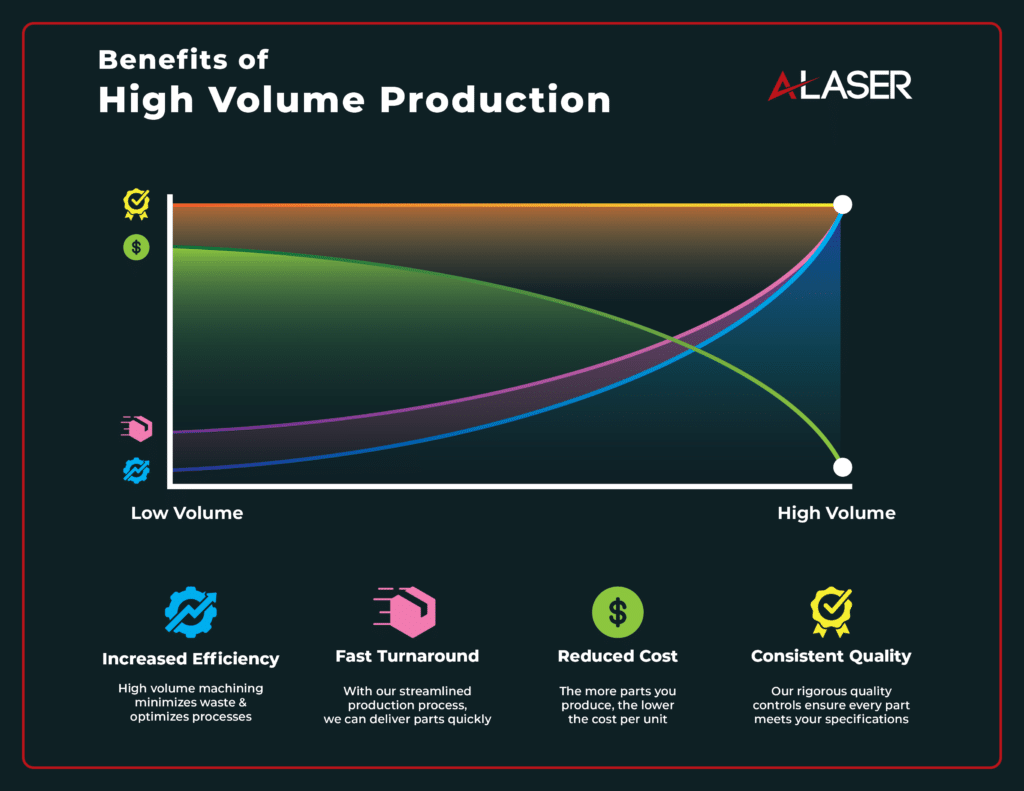

Benefits of High Production Volume:

- Reduced costs: By leveraging economies of scale, high production volume machining allows for significant cost savings. The more parts you produce, the lower the cost per unit.

- Faster turnaround times: With our streamlined production process, we can deliver parts quickly and efficiently, meeting even the tightest deadlines.

- Increased efficiency: High production volume machining minimizes waste and optimizes production processes, resulting in improved efficiency and productivity.

- Consistent quality: Our rigorous quality control measures ensure that every part meets or exceeds your specifications, delivering consistent and reliable results.

Strategies for Success in High Volume Production Machining:

- Invest in the right equipment: Choosing the right equipment for high volume production is crucial. Our advanced laser cutting and machining systems are designed for precision and efficiency.

- DFM (Design for Manufacturing): Early collaboration with our engineering team can optimize your part design for high volume laser machining. R&D plays a crucial role in DFM by refining product designs to ensure they are conducive to streamlined manufacturing processes. Laser development processes, such as prototyping and testing, are integral to this phase, allowing for precise adjustments and validation of manufacturability. Running a sample first enables thorough evaluation of the machining process, identifying potential challenges and fine-tuning parameters before full-scale production. This iterative approach not only enhances product quality but also maximizes production efficiency and minimizes downtime, ultimately leading to a successful high volume machining operation.

- Optimize your processes: Streamlining and optimizing your production processes can significantly improve productivity and reduce costs. We work closely with our customers and team to identify and implement process improvements.

- Partner with a reliable supplier: Choosing a reliable and experienced supplier is essential for successful high volume production. When selecting a manufacturing supplier, thoroughly research their capabilities, reputation, and quality management systems. Request and evaluate quotations from multiple suppliers, considering pricing, quality, and lead times. Conduct site visits or audits to verify their facilities and processes, and communicate clearly to establish expectations. Start with small orders to test reliability before committing to larger volumes, and maintain open communication for continuous improvement.

- Quality control measures: Implement robust quality control measures at every stage of the manufacturing process to uphold quality standards and minimize defects. First Article Inspections (FAIs) are conducted to validate the initial production sample, verifying that it meets design specifications and quality standards before full-scale production begins. Acceptable Quality Limits (AQLs) establish the maximum allowable defect rate in production batches, guiding sampling plans to statistically assess product quality. Spot checks supplement ongoing quality assurance efforts by randomly inspecting finished goods throughout the production process, identifying and addressing any deviations from quality standards promptly. Together, these quality control measures help uphold product integrity, minimize defects, and ensure customer satisfaction in high volume manufacturing environments.

- Flexibility and adaptability: Maintain flexibility in production capabilities to accommodate changing customer requirements and market dynamics.

A-Laser is a proud provider of precision parts services and gladly supports all levels of manufacturing. Contact us today to discuss your project requirements and experience the benefits of high volume production machining.