Laser Cut Thermal Interface Materials (TIMs) Service

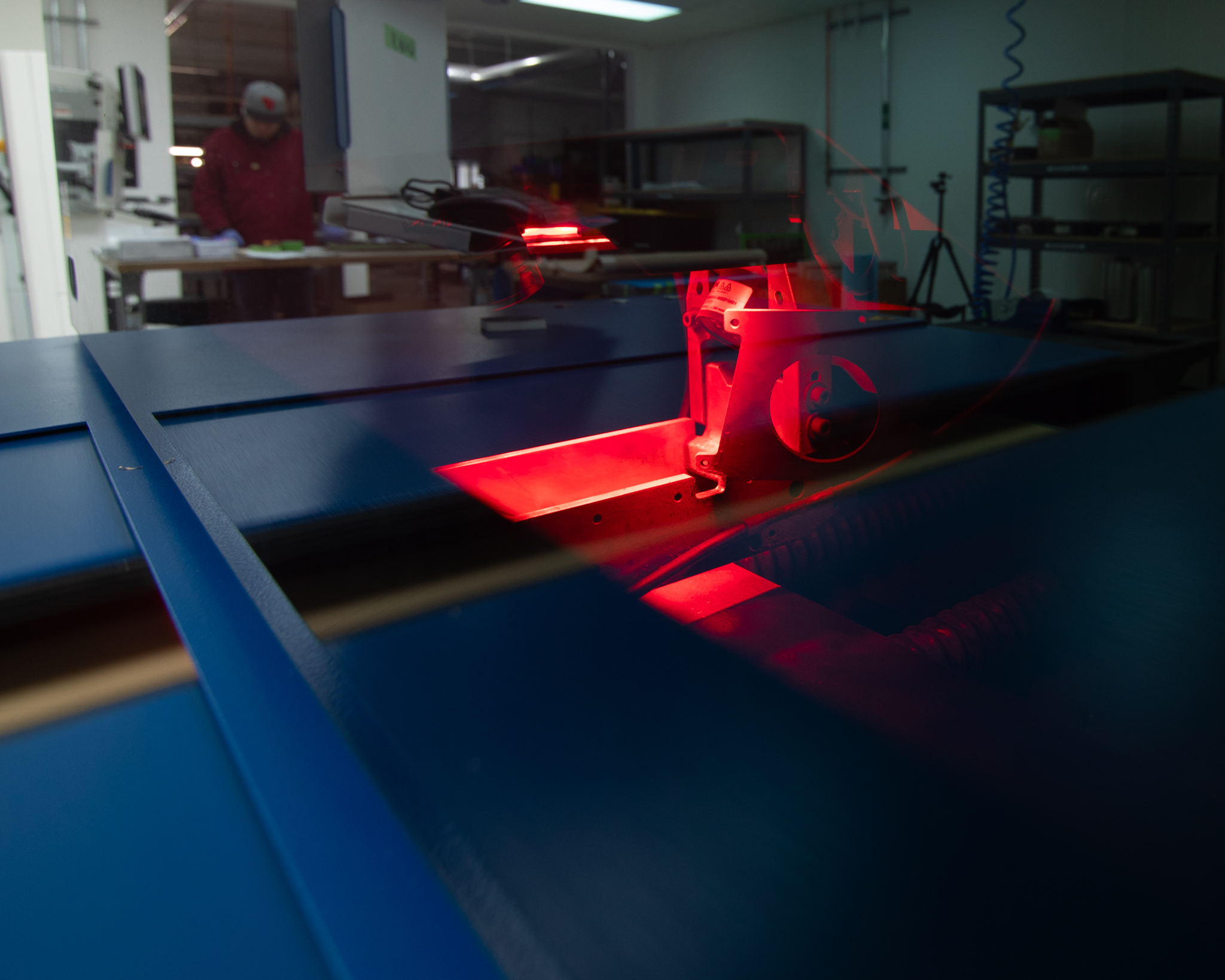

Precision Laser Cutting for Thermal Interface Materials (TIMs)

Shaping Materials That Keep Chips Cool

Precision is critical in thermal management, where even the smallest measurement can have significant implications. Thermal Interface Materials (TIMs) are the hidden heroes that carry heat away from the world’s most powerful semiconductor devices, dissipate heat to heatsinks, keeping electronic devices functioning and other thermal solutions. Our precision laser cutting services help manufacturers form these critical materials into perfectly matched, production-ready parts ensuring that every chip, module, or power system stays cool under pressure.

What Are Thermal Interface Materials?

Thermal Interface Materials, or TIMs, are specialized pads, films, and coatings designed to improve heat transfer between two surfaces typically between a chip and a heatsink. No matter how flat a surface may appear, microscopic air gaps exist that trap heat. TIMs fill those voids with a thermally conductive layer, creating a smooth path for heat to flow away from the chip.

Common TIM Formats:

- Silicone gap pads and gels

- Graphite and Carbon-based films

- Thermal Gap Fillers

- Metal foils (copper, aluminum, indium)

- Phase-change materials (PCMs)

- Thermally conductive adhesives and tapes

Each type offers unique thermal conductivity, compliance, and assembly benefits and each can be laser-cut with precision for optimal fit and performance.

Why TIMs Matter More Than Ever

Modern electronics are faster, smaller, and hotter. With the implementation of A.I. (Artificial Intelligence), the semiconductor industry, battery technology and other high-performance systems are in huge demand for more power and efficiency. The requirements to push power density and integration make heat management one of the defining challenges of next-generation designs and usage of TIMs with factors such as:

- Reliability: Excess heat accelerates component wear and failure. Transferring heat away from sensitive components is paramount.

- Performance: Stable thermal interfaces support higher clock speeds and tighter tolerances.

- Longevity: Consistent heat flow extends device lifespan and efficiency.

Even a few microns of trapped air can create a thermal bottleneck. A well-cut TIM ensures consistent surface contact and uniform heat dissipation down to the millimeter and beyond.

How TIMs Keep Chips Cool

Inside every processor, memory module, and power converter lies a thermal pathway: Silicon → TIM → Heat Spreader → Heatsink. The TIM’s job is to bridge the imperfect interface with a material whose thermal conductivity is hundreds of times greater than air.

- Heat Flow Control: Replaces air gaps with a continuous, conductive medium.

- Mechanical Compliance: Conforms to surface irregularities and maintains contact during thermal cycling.

- Advanced Compositions: Graphene, graphite, and metal-filled TIMs are achieving conductivities from 10 to 500 W/m·K are ideal for advanced chip packaging, data centers, and EV power electronics.

The result: Cooler chips, longer life, and higher sustained performance.

TIMs and the Semiconductor Future

From high-performance computing to electric vehicles, data collection centers, high speed communications and so many more applications, semiconductor packaging is evolving rapidly and needs the performance reliability of TIMs to keep their chips in top performance. Each generation increases the thermal load, making TIM design and precision manufacturing indispensable.

- AI and Data Centers: GPUs and CPUs run at unprecedented watt densities.

- 3D Packaging: Vertical stacking of chips amplifies internal heat concentration.

- EV Power Electronics: TIMs ensure reliability under continuous high load.

- Miniaturization: As interfaces get thinner, precision cutting becomes critical for consistency.

As performance scales, the geometry and application of TIMs become just as critical as the material itself and that’s where precision laser cutting makes the difference.

Why Choose A-Laser for Laser-Cut TIMs

If you are designing or specifying TIMs for industrial applications with custom form-factors (e.g., odd shapes, matched to heatsinks, high volumes, repeated runs) then you should consider laser cutting for these benefits:

- High accuracy and repeatability result in ultra-tight tolerances for thin films and foils.

- Clean, burr-free edges that maintain material integrity.

- In-house inspection and quality documentation.

- Cleanroom-compatible handling and packaging.

- Rapid prototyping without tooling costs.

- Non-contact process ideal for delicate or composite materials.

- Excellent for intricate shapes, slots, and venting geometries.

Laser Cutting Vs other Methods for TIMs

Laser cutting delivers unmatched precision and cleanliness that are two traits essential to maintaining the integrity of thermally conductive materials. Die-cutting and waterjet cutting also are being used to cut thermal interface materials, and each manufacturing methods has a place in industry. For laser cutting however, it has the advantage of being able to process complex materials and geometries that can be challenging by other manufacturing systems.

| Cutting Method | Tolerance | Edge Quality | Suitable Materials | Typical Use |

|---|---|---|---|---|

| Laser Cutting | +/- .5mil to 1mil | Excellent (no burrs, no debris) | Graphite, metal foils, composites. Ultra-thin TIMs | Prototypes / precision parts, supply chain member. |

| Die Cutting | +/- 2mil | Good | Soft TIMs pads, adhesives. | High-volume runs. |

| Waterjet | +/- 5mil | Good | Thicker TIMs pads and substrates. | Large-format components. |

Whether you’re working with graphite foil, metal TIMs, or silicone-based gap pads, precision and cleanliness define our process. By working directly with engineers, material scientists, and procurement teams the material’s structure and its thermal performance remain uncompromised, ensuring that each part performs as designed.

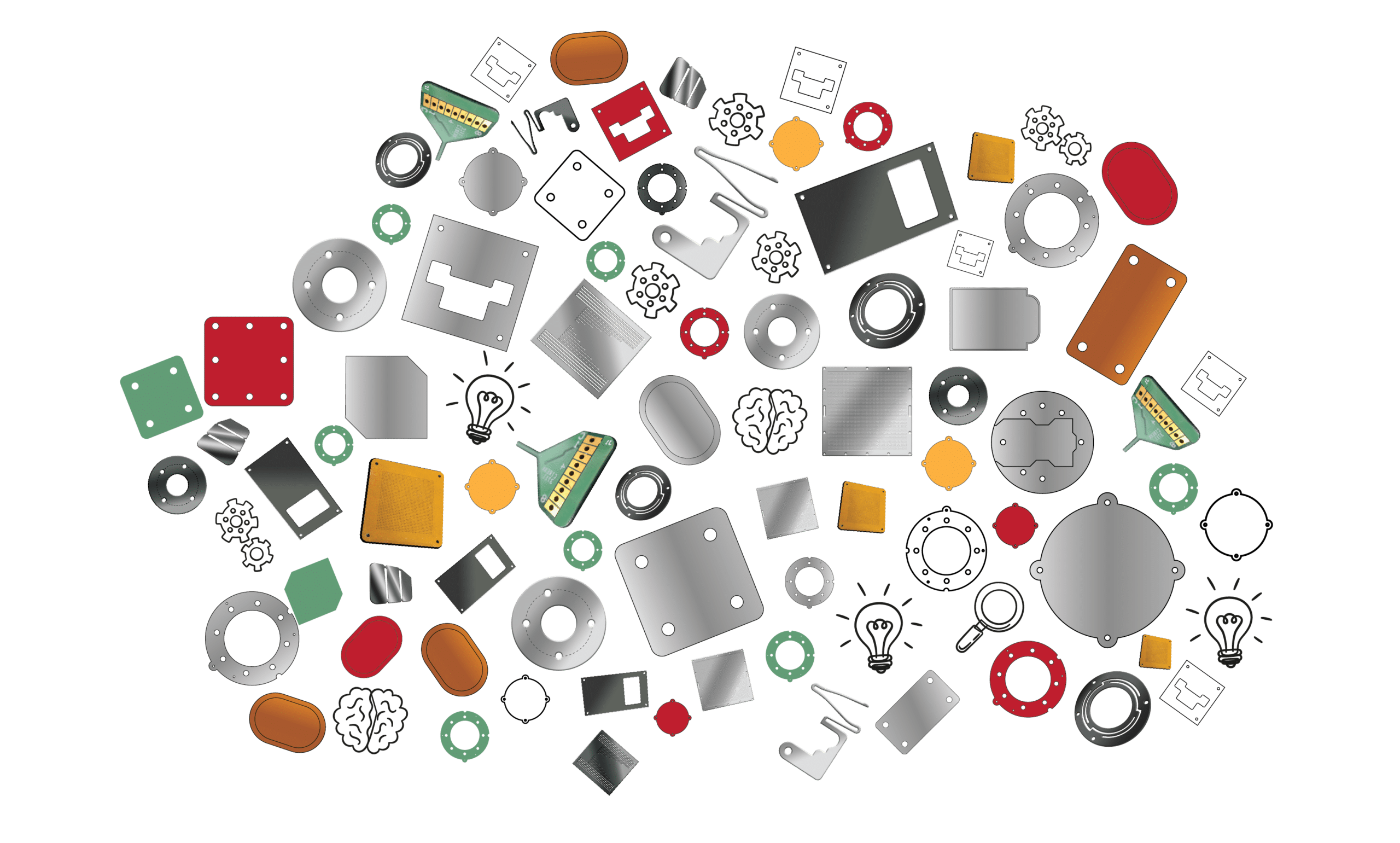

Materials We Commonly Cut

Our UV and fiber laser systems can process a wide range of thermal interface materials, including:

- Graphite film (PGS, flexible graphite, Grafoil)

- Indium and nickel foils

- Kapton/Polyimide

- Silicone or gel-filled thermal gap pads

- Aluminum-coated polyimide films

- Thermally conductive adhesive tapes and laminates

Each cut is optimized for edge quality, dimensional stability, and compatibility with downstream assembly.

Industries We Support

Because thermal interface materials play a critical role in managing heat across advanced electronics, our laser cutting capabilities are essential for delivering precision components tailored to demanding applications. By expertly processing various TIMs with consistent quality and accuracy, we enable manufacturers in a diverse range of sectors to meet their unique thermal management requirements. The following industries rely on our expertise to ensure optimal performance and reliability in their products.

- Semiconductor and IC packaging

- Power electronics and converters

- 5G and telecom hardware

- Electric vehicles and battery modules

- Aerospace and defense systems

- Space Telecom

- LED and display assemblies

Enabling Next-Generation Thermal Management

From the smallest processor to the largest power module, the future of performance depends on effective heat management. Our precision laser cutting services empower manufacturers to shape thermal interface materials (TIMs) with unmatched accuracy. This process ensures each component achieves an exact fit, maintains clean edges, and establishes reliable thermal pathways that are key factors that are essential for every generation of technology. By delivering consistently precise TIMs, we help manufacturers meet evolving thermal challenges and enable tomorrow’s innovations.