Going Beyond the Basic Project

A custom laser cut project begins not with a declaration, but with a series of questions and answers when a customer reaches out for laser services. They know what result they need from the precision part and the function it will have, but the manufacturing process can be unclear. That’s a typical beginning of communication between a service provider and prospective customer. The uncertainty of capability, of material, of tolerance and other factors are all considered and then a bit of detective work ensues. Meetings between these two parties will undoubtedly uncover any challenges and through all a better understanding of the project’s needs will be revealed. Is every laser cutting project a custom project? The answer is no, and a simplified example of a standard laser project is one where the material and or application is confined to geometry, tolerance and quality within the limits of established laser parameters. For a custom project a well-established laser service provider will harness the resources of experience, of staff, knowledge of materials, and machine capabilities. These type of projects do take more time but the importance of discovering new methods and processes that advance burgeoning technologies is of great relevance and importance.

An example of this was a project in support of the aerospace industry. The foundation of the project needed a polyimide gasket with an acrylic adhesive to be placed onto a plate made from aluminum. These plates would be manufactured by CNC manufacturing processes, but CNC technology could not cut the 5mil polyimide. Furthermore, the gasket needed to be accurately cut and placed within a tolerance of +/- 0.0127mm. The cut edge could not have excessive charring nor any burrs. Discussions demonstrated that prototypes were successful, but the loss of good assemblies proved cutting single gaskets were not going to support any level of production nor withstand the scrutiny of quality control. When a deeper investigation was conducted, it was clear that the gaskets needed to be cut in place. This would avoid the errant application onto the plates and give a potentially high level of production. Could laser technology

be processed in such a way? Through laser development, which included refinement of the laser parameters to cut the polyimide accurately and without discoloration, to adjust the laser bed in such a manner as to allow the focused beam to cut and to develop a process for securing and aligning to each plate. This indeed was not a standard laser project. The communication between the customer and manufacturing allowed adjustments to be made once the first prototypes were collected and feedback was given. This one example is typical to custom laser cutting projects. The details change but the process follows and is supported by procedures put in place by having a QMS or quality management system.

Driving Technological Advancements

The example of the polyimide gasket was developed on an ultraviolet or UV laser system, but each laser type and every manufacturing method has custom projects that go beyond the normal established process. To help in how laser technology supports custom work, the following additional list of examples shows a glimpse into the range of projects that laser technology supports like

- Medical Device: For outpatient procedures, many devices are developed for one-time use. In developing such technology, the device must work one hundred percent of the time. In treatments, one such project needed peek tubing to be accurately laser drilled. Requirements included accuracy and repeatability for production volume. The device involved plasma energy, and the peek tube is critical in confirming pressure integrity and that the plasma was contained only to the treated area during the procedure.

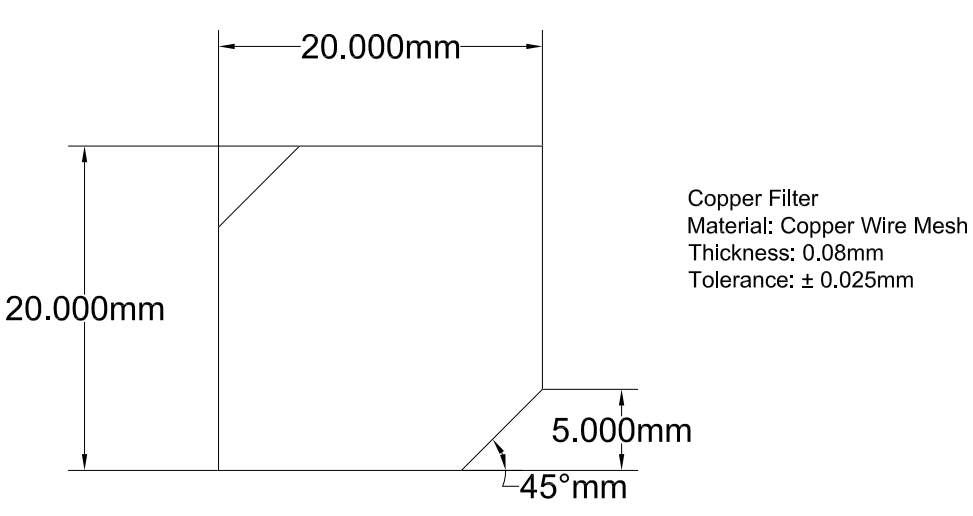

- Wireless Energy: Technology such a wireless power is growing and in has high expectations and demands for multiple iterations. Laser systems such as ultraviolet and fiber laser are cutting copper and nickel and other supporting materials. Accuracy requirements are at +/- 0.0127mm to 0.0254mm.

- Battery Technology: We now have cars, trains, buses and bicycles that are run by battery technology. The expanding research in developing batteries to store more energy and be more efficient is pushing technology in both developing manufacturing processes and materials. Laser technology using infrared for cutting stainless steel alloys, fiber lasers for cutting nickel and copper and ultraviolet systems for cutting polyimide, thin copper, and nickel foils, developing laser settings and procedures to produce these delicate geometries with tolerances of +/- 0.0127 to 0.025mm.

- CHIP Manufacturing: A good example of custom laser cutting is in support of chip manufacturers. They needed a better way to secure and inspect electronics chips and be able to automatically align and process the inspection. This project required precise laser cutting of plates made from stainless steel and aluminum. By working with the customer, the best process to produce the needed geometry and then evaluate which post processing service to deburr was developed. Each plate would have designated alignment points to aid in the inspection of these chips. Flatness was paramount, so the laser parameters were fine tuned to prevent any HAZ or heat affected zone.

Making The Magic Happen

Developing a new product or improving on an existing technology can be long process and since many products can directly affect out lives, being prudent is the best way to solve these challenges. As mentioned earlier, communication and cooperation between the customer and laser service provider will help in selecting the best path forward. Sometimes laser technology is not the best choice for a project, but knowing this may guide you into other alternatives such as CNC technology, waterjet laser, plasma laser, die-cutting and stamping. These methods all have attributes that are valued and used for countless projects, both in R&D and volume manufacturing. To aid in your early evaluation and decision making for custom laser cutting, the following information can be used as general guide:

Conclusion

Custom laser cutting has emerged as an invaluable tool for businesses by revolutionizing the manufacturing process. By offering unparalleled precision, intricate detail, and versatility, laser cutting surpasses traditional methods in efficiency and quality. Whether you’re crafting proof of concept prototypes, producing small-scale items, and will need volume manufacturing support laser cutting provides the flexibility to bring your designs to life with stunning accuracy. Its ability to cut a wide range of materials, from delicate polymers to metals, expands the creative possibilities and opens doors to innovative solutions. Experience brings knowledge so when in communication with your prospective service provider, please do ask what type of custom projects they have processed and what was the solution. Their expertise should give you a valuable edge in determining if laser technology is the right choice to funnel your ideas into a tangible precision part.