Laser Cut Stainless Steel

Laser Cut Stainless Steel

What laser(s) can cut stainless steel?

Since its development back in 1913, stainless steel has been a material sought for its corrosion resistant properties. Though numerous technologies are used to manufacture parts out of SS, lasers are one of the more “recent” available solutions.

How do you laser cut stainless steel?

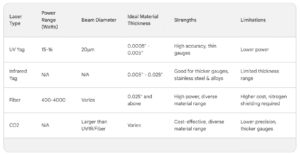

Laser cutting stainless steel is a relatively simple process that does not generally require complex set up or tooling. The choice of laser technology is critical for success and the best outcome. Consideration for the thickness, the geometry to be cut and the final use of the manufactured part will guide what type of system is best:

- UV or Ultraviolet – These systems use a very small beam diameter, in conjunction with low power use. Often the only choice for stainless steel foils from .0005” up to .005” mils thick. Used for projects requiring tight tolerance, smooth, clean edges.

- Infrared – Being slightly higher in power over, UV- IR laser is a great choice for thicker gauges of stainless steel, but still having a small kerf and tight accuracy. These types of lasers capture thickness best between .005” mil up to .025” mils thick. Greater use for production and throughput.

- Fiber laser – This type of technology is higher powered and can come in wattages of 400 to 4000 for example. Produces faster cut times. The lower power end systems bridge the gap from laser to other technologies, like CNC, Waterjet.

- CO2 lasers – Generally not as accurate and has larger tolerance. Good for projects that need the geometry cut, but not for tight tolerance nor critical precision parts.

What are the expected outcomes when using a laser to cut stainless steel?

- High precision cuts: Lasers deliver incredibly thin kerf widths (the width of the material removed by the laser) compared to traditional cutting methods, minimizing material waste and ensuring tight tolerances. Laser cutting offers tolerances as tight as +/- 0.0005”.

- Complex geometries: Lasers can tackle intricate geometries impossible with traditional tools, expanding your design possibilities.

- Heat-affected zone (HAZ) minimization: Unlike mechanical cutting, lasers create minimal HAZ, preserving the inherent strength and corrosion resistance of stainless steel in the cut area.

- Edge quality: The laser cutting process utilizes a very small highly focused spot which minimizes the impact on the material, producing cleaner and smoother edges to a high tolerance. Complemented with our post-laser processes, the edges are clean and burr-free.

- Reduced tool wear: Unlike mechanical tools that wear and tear, lasers require minimal maintenance and offer consistent performance over extended use.

What criteria influences the cost of laser cutting? How much does it cost to laser cut stainless steel?

Numerous factors can affect the cost of laser cutting, and it varies by supplier. A few items that may be taken into consideration are:

- Material type: Different materials have varying levels of difficulty when it comes to laser cutting. Some materials may require more power or slower cutting speeds, affecting the overall cost.

- Material thickness: Thicker materials require increased laser power and processing time, driving up the cost.

- Complexity of the design: Intricate cuts with tight tolerances or numerous features will generally cost more than simple straight cuts.

- Size of the part: The cost for laser cutting is directly proportional to the process time, which is a result of the linear distance the laser must travel and the speed at which it travels. Larger parts (higher linear distance) will have a higher cost due to the longer processing time required.

- Volume: Ordering larger quantities often qualifies for bulk discounts.

- Tolerance and precision requirements: Tighter tolerances and higher precision may require more careful and slower cutting, affecting the cost. The level of precision needed for the project can influence the choice of laser cutting equipment and cost.

- Cleaning requirements: Depending on the material and type of cut, there are several cleaning options to refine the quality of the cut post-laser, depending on the quality and surface finish requirements.

- Packaging requirements: These differ depending on the project and type of part that is laser cut. More intricate packaging will require additional time to complete, hence higher cost.

- Additional services: Such as finishing, plating, forming.

With all of that in mind, here is an example of pricing based on the following parameters:

- Stainless Steel thickness 0.010”

- Tolerance +/- 0.001”

- Part is a Square that is 1”x1” in size.

For more information on calculating laser cutting costs, check out our Laser Cutting Cost Estimator.

Can lasers engrave stainless steel?

Yes, laser engraving on stainless steel is possible. However, its feasibility depends on various factors, and there are challenges and consequences that may arise during the process.

Challenges of laser engraving stainless steel:

- Chromium oxide layer: Stainless steel’s protective layer, while great for corrosion resistance, absorbs laser energy poorly, making deep and precise engraving difficult.

- Heat sensitivity: Too much laser heat melts or distorts the metal, ruining the engraving and potentially damaging the piece.

- Gas pockets: Certain laser wavelengths react with the chromium oxide, causing unsightly bubbles within the engraving.

- Precise control required: Laser engraving stainless steel requires carefully adjusted laser power, pulse duration, and focus, which can make repeatability difficult.

While laser engraving on stainless steel is possible, understanding the material properties, using the right laser type and power settings, and conducting thorough testing are essential to overcome challenges and achieve successful results. The consequences of inadequate control over these factors may include poor engraving quality, material damage, or undesired alterations to the stainless steel properties.

Alternatives to laser engraving include laser annealing or chemical etching:

- Laser annealing: Heats the metal to create visible contrast (black markings) without removing material. Easier to control and preserves corrosion resistance, but lacks the depth and detail of engraving.

- Chemical etching: Uses chemicals to create a permanent design. Less precise than laser methods but can be cheaper for large quantities.