Kapton Tape

When a laser is used on Kapton, it can be used to selectively remove or ablate the adhesive layer without damaging the underlying substrate.

Kapton adhesive is a high-performance adhesive tape that is widely used in various industries for its excellent thermal and electrical insulation properties. Made from a polyimide film, this adhesive tape has a unique combination of properties that make it an ideal choice for many applications.

One of the main benefits of Kapton adhesive is its high-temperature resistance. It can withstand temperatures up to 260°C (500°F) without losing its mechanical or electrical properties, which makes it ideal for use in high-temperature applications. For example, it is commonly used in the aerospace industry to insulate wires and cables that are exposed to extreme temperatures during flight.

Another advantage of Kapton adhesive is its excellent electrical insulation properties. It has a high dielectric strength, which means that it can withstand high voltages without conducting electricity. This property makes it an ideal choice for electronic applications where insulation is critical, such as in the manufacture of printed circuit boards.

Kapton adhesive is also resistant to a variety of chemicals, including acids, oils, and solvents. This makes it an ideal choice for use in harsh environments where exposure to chemicals is a concern, such as in the automotive industry.

In addition to its excellent properties, Kapton adhesive is also easy to apply and can be cut to size to fit a wide range of applications. This makes it a versatile adhesive that can be used in many different industries and applications.

Some common applications of Kapton adhesive include:

- Aerospace industry: Kapton adhesive is commonly used to insulate wires and cables in spacecraft and other aerospace applications.

- Electronics industry: Kapton adhesive is used in the manufacture of printed circuit boards, as well as in the production of electronic components.

- Automotive industry: Kapton adhesive is used to insulate wires and cables in vehicles, as well as in other automotive applications

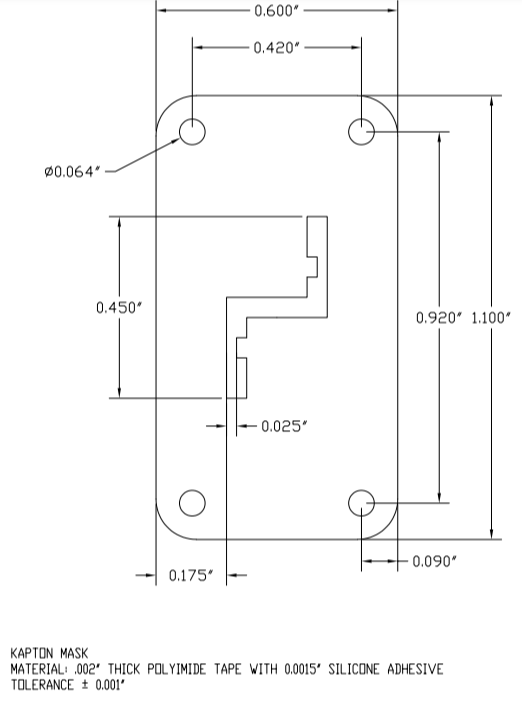

For Kapton tape we can go higher in thickness. We cut polyimide material up to 0.040” thick and can cut with an added adhesive. We see requests for Kapton tape for thicknesses lower than 0.010”, and we can process as low as 0.0005” (1/2 mil).

The minimum tolerance we can achieve on feature sizes is +/- 0.0005” and there is less concern about geometry when processing Kapton tape material. We also offer a kiss cut option where the laser cuts through the Kapton and adhesive layers, stopping at the liner. This is mostly beneficial when working with very tiny parts that would be very difficult to handle individually to try and remove the backing liner one by one. When kiss cut to the backing liner on a sheet, it is easier to maneuver the sheet to peel out the individual masks for use. This material is mostly used as a mask to protect electrical components.