What Is the Minimum Hole Size for Fiber Lasers?

The minimum hole size that a fiber laser machine can cut is related to the characteristic of the selected system, the material and thickness, along with other factors. It is understandable why the question of minimum hole size comes up so often in laser manufacturing. Innovation pushes the status quo and often smaller and smaller scales are part of the new direction that devices and components are designed too. Smaller micro-level holes can be a part of many industries from food processing to sensors, to drug delivery devices. Precision holes are being cut from different manufacturers and methods and for fiber lasers, the characteristics and reliability of the technology, has made it a go to process of laser manufacturing.

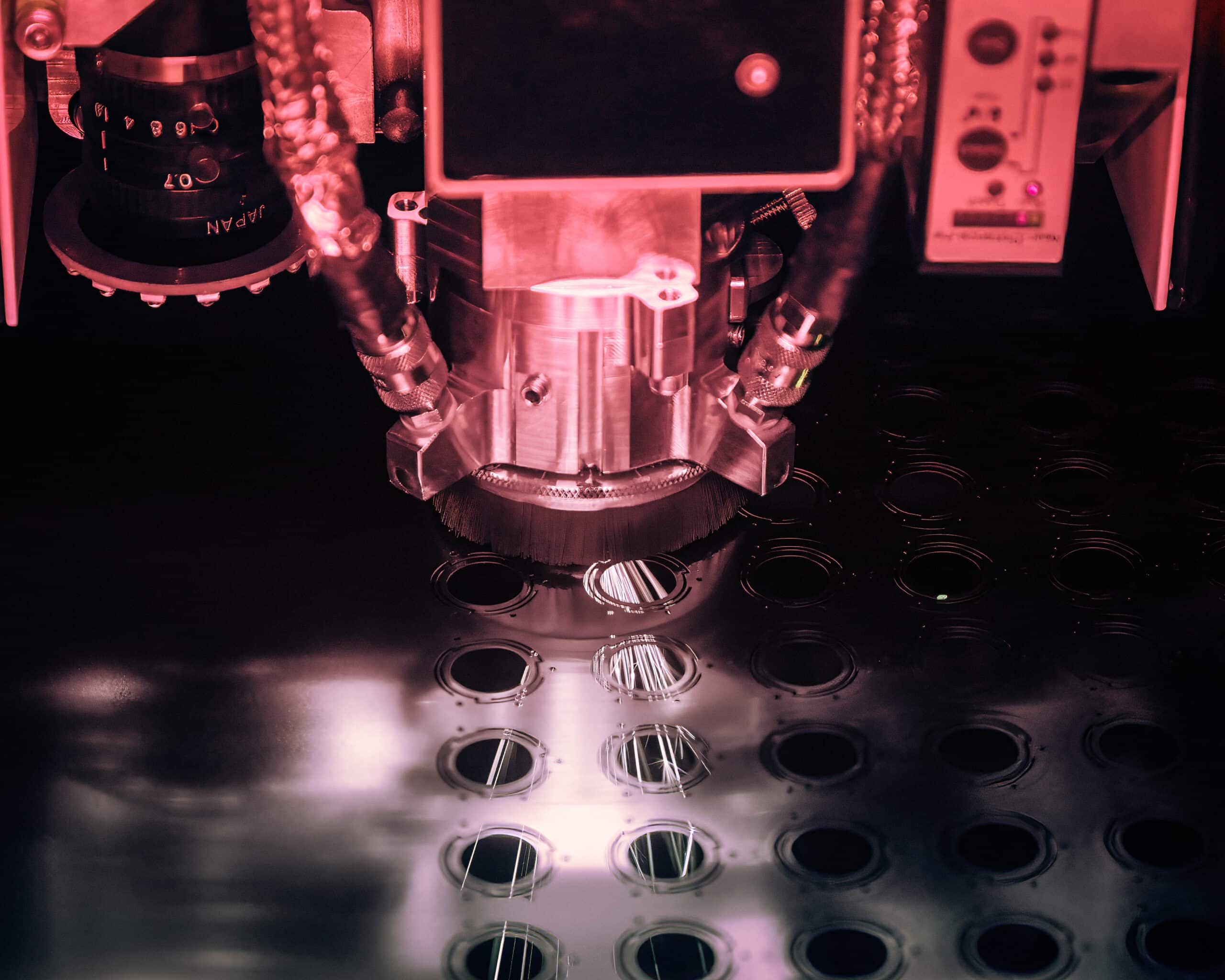

How Are Small Holes Cut with Fiber Lasers?

In brief, fiber laser cutting machines will have optical fibers made from silicate or phosphate glass, which are mixed with rare earth elements of emitted wavelengths such as neodymium (780-1100nm), erbium (1460-1640nm), ytterbium (1000-1100nm), for example. The doped or mixed glass fiber optics absorb light from pump laser diodes and result in a laser beam with a wavelength attributed to the rare earth element used. Fiber lasers can have single, dual and may also come in multi-laser head configurations, with each head have a specific beam diameter. The power or wattage of fiber lasers is broad and can be from a few hundred watts to 15kW of power! The impressive number of variants of fiber laser technology, allows a broad range of manufacturing capabilities from thin metal sheets to thick slabs of metals plates.

One system, for example, has two laser heads, one with an 18micron diameter and the other with a 35micron diameter. Processing with 400 watts of power, the smallest hole cut in 10mil stainless steel is going to be about 0.0127mm and for cutting 80mil thick stainless-steel plate, the smallest hole size is going to be between 0.254mm to 0.382mm. As the power of fiber lasers increases, the ability to cut greater thicknesses increases. However, the minimum hole size will be larger than systems cutting much thinner gauges. No laser system can cut hole diameters smaller than the beam diameter. Generally, the minimum hole size is equal to the material thickness being cut. Micron level hole diameters are done by different laser technology, such as femtosecond and picosecond systems.

Hole Sizes and Tolerance

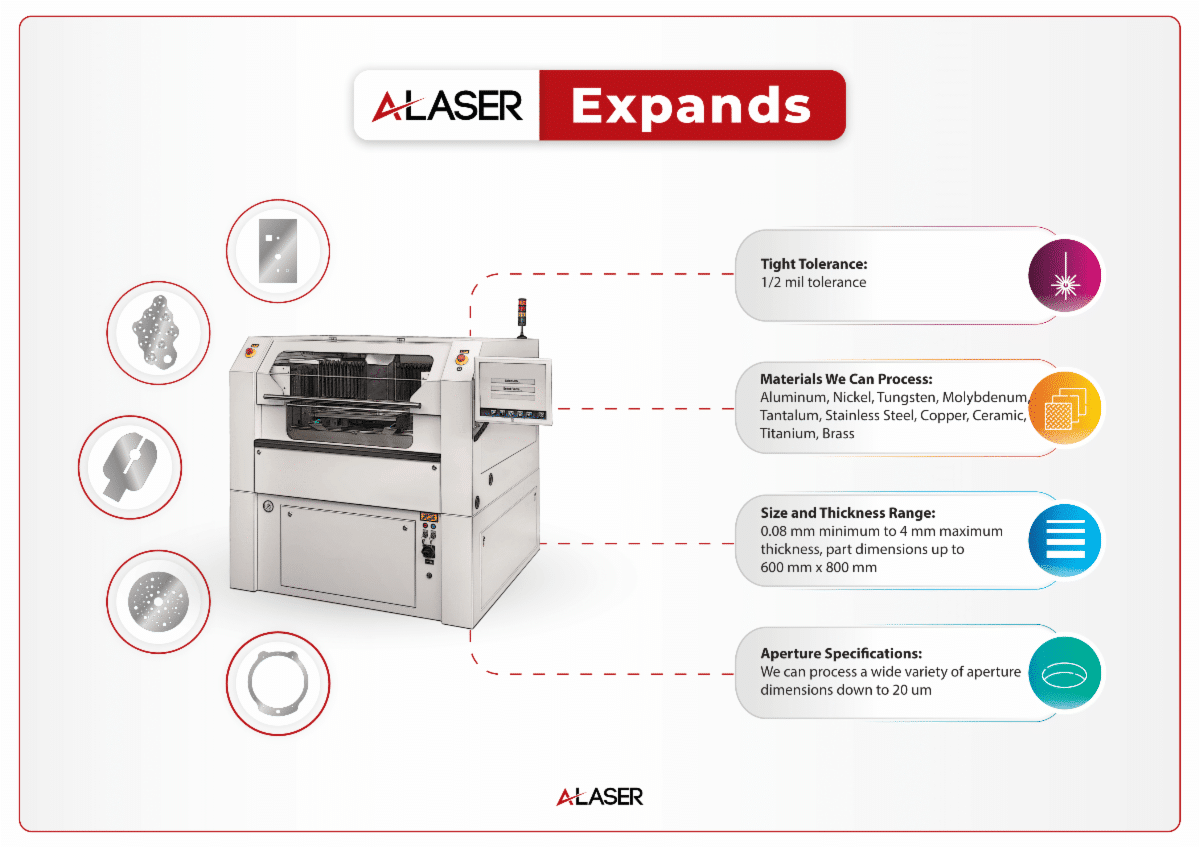

There is a correlation between hole sizes and tolerance and they are especially important as the cut holes and geometric features get smaller and smaller. Fiber lasers come in numerous system capabilities for materials and power output. For higher powered systems with the ability to cut thicker gauges of metals, the tolerance will be greater, than a lowered power system. The trade off has more to do with what is achievable in a tight tolerance, but the quality will be like all fiber laser technology with smooth walls and flexibility in materials. For smaller holes, a tolerance expectation is +/- 0.0508mm to 0.0762mm. Cost for tighter tolerances of any manufacturing method can increase as stricter controls for tolerance are demanded. A review of DFM or design for manufacture, can highlight potential challenges and prevent manufacturing delays brought on with design specifications that may not be needed. Tolerance control is important and is subject to the stages of the project that may start in R&D and prototype, with a looser tolerance and move to volume manufacturing where tighter controls are needed.

In Conclusion

Fiber lasers are used in many ways for numerous industries and applications. As a non-contact cutting method, fiber lasers bring excellent precision along with efficiency, durability and cost effectiveness. Most projects do not require additional tooling and they are reliable with long service life. Designed to take advantage of different wavelengths and coupled with varying power output, fiber lasers can cut holes within their capabilities with clean walls and minimal debris. For further information, please visit your preferred laser providers website and speak with their local representative to determine if their fiber laser machines are the best fit for your next project.