The Technical Side of SOMABLACK

Laser cut parts are not necessarily the first option that comes to mind for consideration of a manufactured precision 2D part. There are multiple methods available to industries seeking support. Often the goal of the request proves to be the reason why one technology is chosen over another. Available for the manufacture of a precision part includes die cutting, stamping, CNC, wire EDM, Electro-forming, laser cutting and 3D printing. There are more of course, but these tend to be the methods most often used for support requests.

How does one choose what technology is suitable? Allow your experts to guide you to what works within their capabilities. When a project comes in and it is out of our capability I recommend to a prospect another technology, other than laser cutting. I know what we can and cannot do. Good will goes a long way and new business relationships can start. Sometimes materials come in that were processed by one method, but the outcome is not satisfactory to your needs. We had a project where materials with polyester and carbon color, were die-cut, but the edge quality was crimped and rounded in some areas. This project started with low quantities in an R&D phase. As time progressed, the material called SOMABLACK, has become a frequent request by customers. It has many properties needed in multiple industries and it cuts extremely well with a clean straight edge our laser systems, which are YAG UV technology. An example of SOMABLACK is listed below:

- SOMABLACK H- Polyester film in which carbon black is mixed. Double sided matte finish, electrical conductivity and sliding properties. H-products have high shading property.

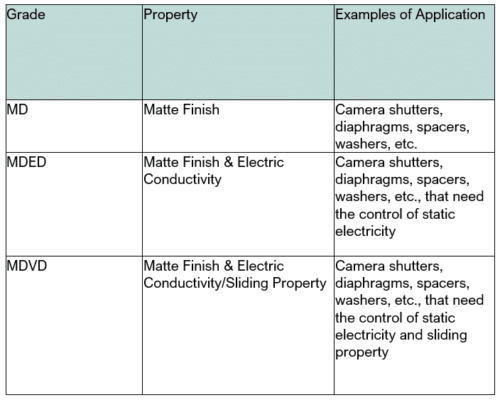

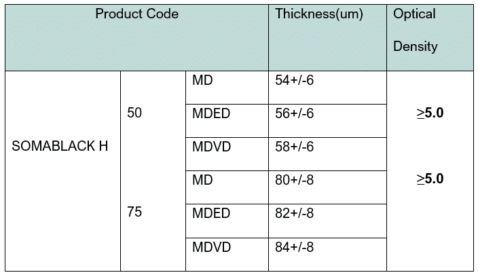

Product Line-up and Properties for H and R*

Grade Line Up for H*

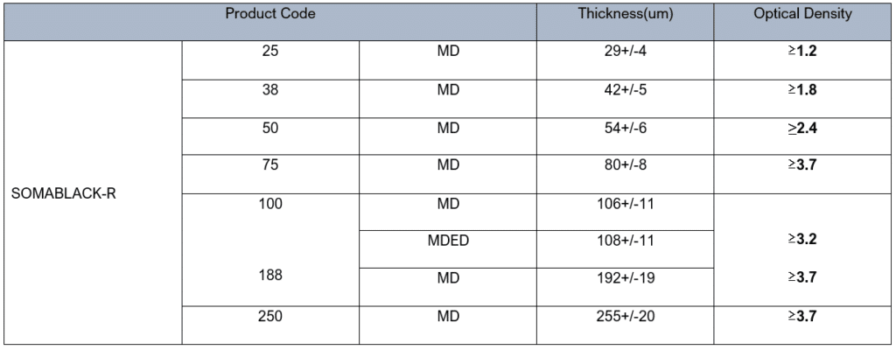

- The R series is a black colored base film with low gloss and non-reflection characteristics. Great for use in optical instruments.

Grade Line-Up for R*

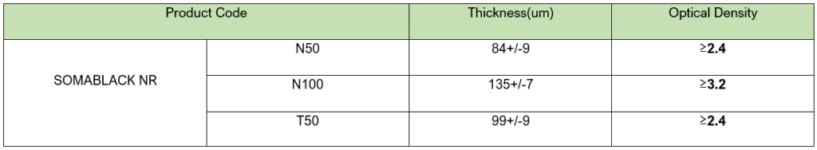

- The NR series is black colored with a transparent base film. The characteristics having matte finish with anti-static, heat resistance, low gloss and high light shading.

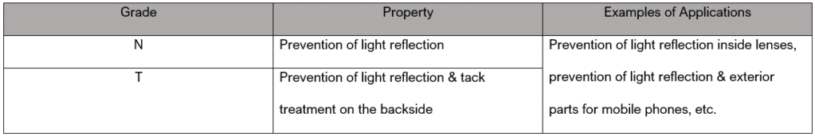

Product Line-Up and Properties for NR*

Grade Line-Up for NR*

As a provider of precision laser cut parts, I can attest to the technological match we have found with laser cutting SOMABLACK material. There are numerous grades available that were not mentioned, so please review which grade would be benefit your project and contact A-Laser for a review. Good luck and every inquiry is welcome!

*Table information provided by Somar Corporation