Simplicity: The Foundation of Genius

As engineers we often find ourselves seeking out complexity and building intricacies in our solutions. The constant strive for better optimisation or streamlined processes can often blind us to the simple things that make life so much easier.

One of my personal favourite examples of simplicity in design is the humble ring pull on a soda can. The aluminium container itself is another story of development and efficiency. The ring pull however has a tonne of interesting features of its own. Consider the development of a portable drinks container originally used to transport liquids from factory to store to home. Quickly people felt the need for an on the go product. The first step was to use a can opener to pierce the container in two places, one as an outlet and one as an air inlet to allow for smooth pouring. The problem of carrying a tool around limited the convenience aspect. Manufacturers introduced an etched pattern on the surface connected to a small ring. This could be pulled back and the waste section discarded. Thus requiring no additional tools. We are a step forward but now we have an issue of sharp metal being discarded on streets, parks, and beaches.

Following this the beverage can industry began investigating the use of “Stay tabs”, ring pulls which would remain attached after opening. There are two major changes in this new concept: the sharp waste section would remain attached to the can but not protruding and the method of force applied would have to change. To achieve this the opening method would change from a pulling and peeling motion to a pressing lever motion. There was one major problem though, to press a tab into a pressurised container would be very difficult. The internal pressure would be around 2-3 atmospheres. This gave a new challenge of needing to relieve the pressure in the can before opening.

Leveraging Opportunity

The ring pull of which we are familiar with today is a thing of genius. By using the same integrated tool to relieve pressure within the can and open the tab manufacturers were able to save on materials and cost. Below we will look at the genius hidden in a simple can of soda. First, we should understand the different types of levers.

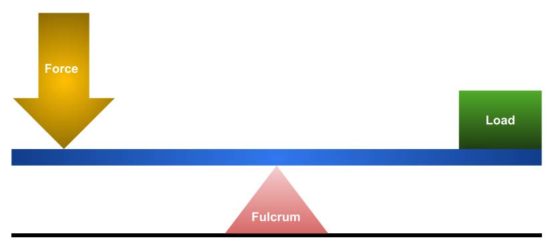

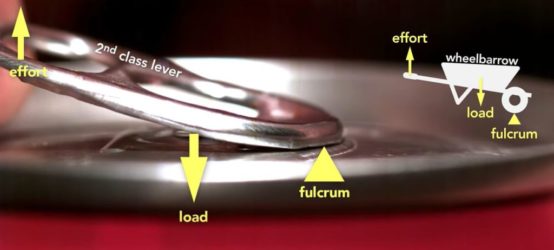

Class 2 Lever

A class 2 lever is where the load is set between the fulcrum and the point where work is being applied. This configuration can be seen in the use of a wheelbarrow. With the fulcrum at the centre of the wheel, the load in the bed and the work being applied at the handles. This setup allows less force to be applied to move the load by utilising torque. There is a tradeoff though for every bit of force saved more distance will have to be covered to achieve the desired result.

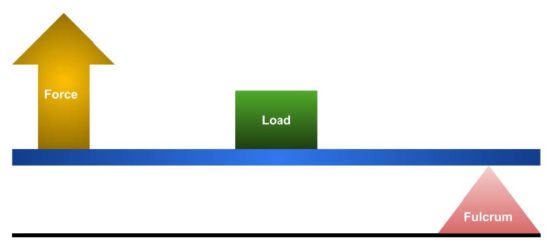

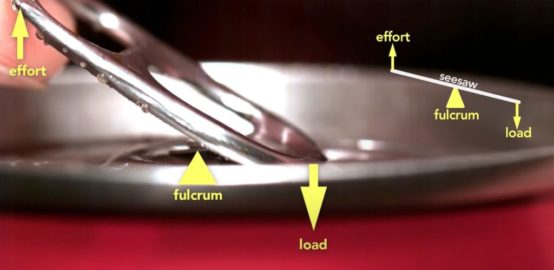

Class 1 Lever

A class 1 lever has the fulcrum placed between the work point and the load. This method enables a force to act in the opposite direction of work being applied. Children playing on a see-saw take alternating turns on a class 1 lever of being a force or being a load.

The Solution

You may be asking what all this has to do with ring pulls. The first act of opening a soda has the ring pull acting as a class 2 lever with the loop being the work point, the centre rivet as the load and the tip as a fulcrum. The upwards force on the rivet along with the pressure inside the can pushing out will force a small opening which immediately drops the pressure and creates a small fracture in the lid.

In an instant the ring pull becomes a class 1 lever with the work point remaining the same, the rivet now becoming the fulcrum and the tip acting as the load point. Continuing with the original motion the tab is folded inside to protect from sharp edges.

This results in the tab being folded inside unable to harm the consumer. As an added bonus the ring pull can be rotated to hold a drinking straw in the can without floating out.

Simplicity doesn’t always mean easy or obvious, simplicity can be the ability to remove a decision point from a process, to remove the need for tools or to offload the work to an automated process. Real simplicity in design is almost never seen, rather it’s experienced without awareness. Engineers are always looking to improve the world in which we live. This may come from a groundbreaking discovery or it may be from a small improvement that marginally affects millions of people around the world each day. When working on problems try to ask what can be removed to eliminate a cause rather than dealing with the symptom.

Credit to Bill Hammack of Engineerguy for inspiration on this topic.

About the Author

Robbie is a motivated, focused, and dedicated Laser Engineer at A-Laser. Robbie studied Manufacturing Systems Engineering at Glasgow Caledonian University, graduating in 2013. He then took a graduate role at Tannlin Technology in the UK where he worked on the systems team. His role included product improvement, customer assistance, system building, and engineering analysis. His five years of experience working at Tannlin, often in the field, required thinking on his feet and working with limited resources. Outside of engineering, Robbie enjoys photography, as he likes to keep a part of his life in a creative field so that he can work that muscle when he needs to. Robbie excels in roles that combine technical expertise and project coordination and strives to deliver value to customers. Robbie is highly appreciated for his client-centric approach and his ability to build strong client relationships. If you have questions or want to discuss laser technology, please reach out to Robbie!