What Are the Benefits of Rapid Laser Cutting?

Because speed is everything, not all manufacturing methods can meet the tight deadlines and intricate designs in today’s fast-paced manufacturing landscape. Rapid laser cutting offers a revolutionary solution for service providers, delivering precision, efficiency, and unparalleled turnaround times. Laser cutting services, armed with advanced technology, provide a swift and accurate solution to these challenges. From complex prototypes to large-scale production runs, rapid laser cutting service providers offer a wide range of benefits, including increased efficiency, reduced material waste, and exceptional quality. The following list of benefits are many of the ways rapid laser cutting can support your next project, such as:

Material Capability: Laser service providers can cut a multitude of alloys and non-metallic materials like stainless steel, copper, titanium, aluminum, nitinol, polyimides, Peek, mylar, FR4 and numerous other materials.

Data Options: Manufacturing laser cut prototypes and production runs, can be processed through customer supplied CAD data of DXF files, Step files, gerber files and others. Many precision laser manufacturers have capabilities to create files as well.

Complex Designs: Laser technology can create intricate designs in a short amount of time that would be challenging or impossible by other methods.

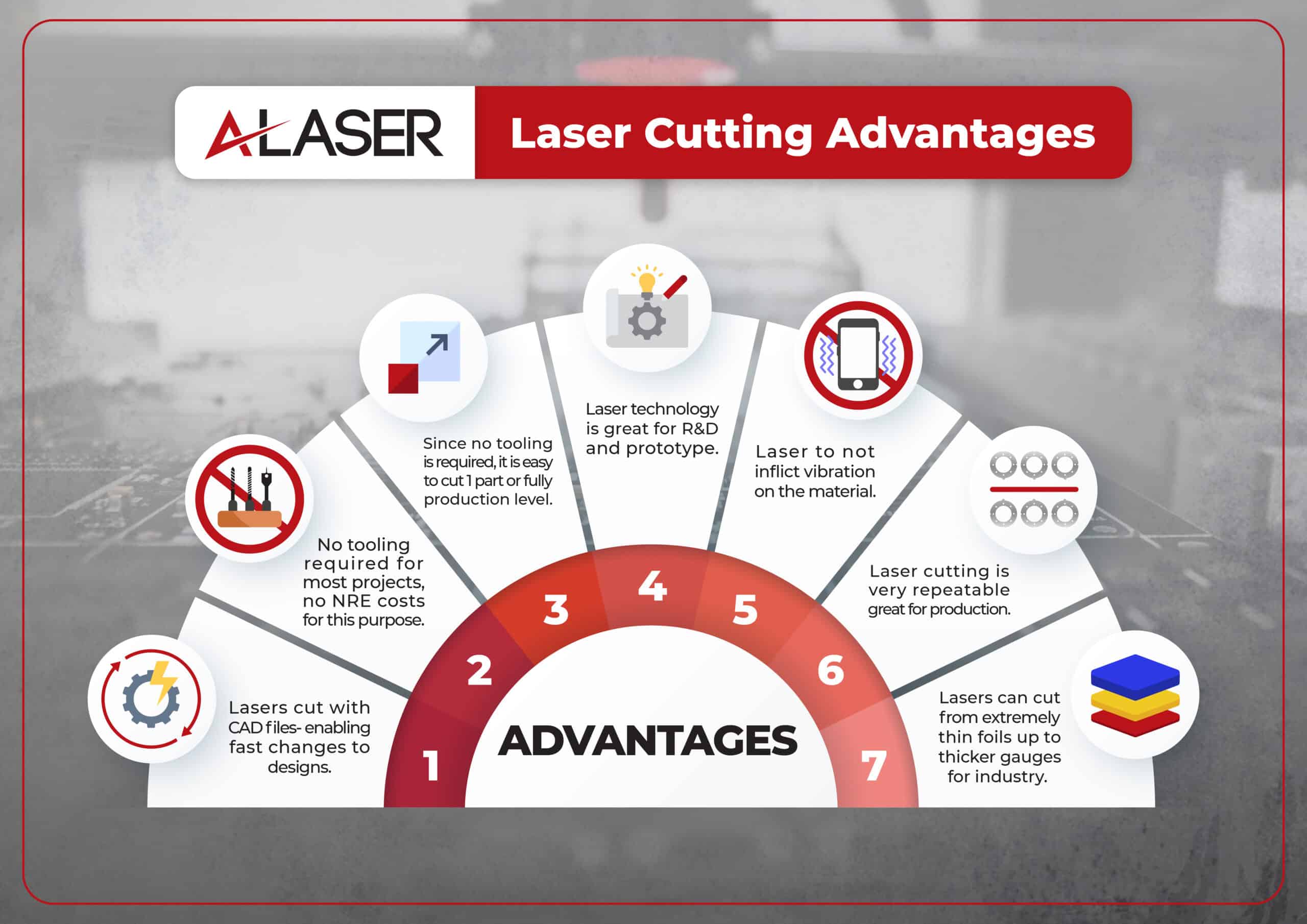

Multiple Iteration Support: Since laser technology does not typically require special dies, tooling, or other NRE costs, set-up is faster than many other methods. This supports rapid iterations to be made within the same production run. Customers can be supplied with multiple versions of a prototype in a short time.

Quality Assurance: To better support customers, quality inspection systems are used to confirm the manufactured components are within the tolerance of each project. Many service providers ensure their quality standards by becoming certified under ISO 9001, ASM 9100 and other industry standards.

Low to High Volume: With rapid laser cutting, you can produce a minimum quantity for an evaluation run. Once that is approved, a larger quantity cycle can be produced since the laser settings and set up will remain the same.

Efficiency: By nesting of parts to gain maximum quantities and save material for future customer needs.

Customizable Designs and Solutions: The ability to meet specific customer needs can enhance customer satisfaction and build strong relationships. Laser cut prototypes may need customized laser settings and procedures that can be readily adapted and implemented.

New ideas and concepts have always been the fuel for increasing our knowledge and understanding of how things are now and what can be done to make something better. Rapid laser cutting has become a valued asset to customers seeking to take technology further and into a tangible reality. Whether you’re in the aerospace, automotive, or electronics industry, laser cutting technology has the potential to revolutionize your operations. Service providers can offer tailored solutions to meet the unique demands of your specific sector.

What Machines and Programs Do You Need for Rapid Laser Cutting?

The process of rapid laser cutting involves a host of laser machine technology, quality inspection systems, and quality management programs. Additionally, a robust customer service and production team are needed to coordinate from the onset of a customer’s inquiry to final shipment of the project. These elements work together to provide highly accurate and quality driven components to numerous sectors of industries like semiconductor, communications, optics, medical, textiles, aerospace and the list could go on and on. The following table is an indication of the systems harnessed to keep pace with the expectation of advancing technology:

| Systems/Programs | Capabilities | Special Notes |

|---|---|---|

| Laser Systems | Many laser manufactures employ several laser systems. This allows versatility and flexibility in types of materials and projects they can support | Laser systems require scheduled maintenance and calibration. Laser cutting is a cleaner process than other methods with no coolant or liquids involved in the cutting process. |

| Ultraviolet (UV Laser) | UV lasers are versatile machines capable of cutting numerous materials including stainless steel, copper, nitinol, peek, polyimides. Accurate to +/- 0.0127mm | UV laser can be lower powered so cutting materials will be thin sheets or foils. |

| Infrared (IR Laser) | IR lasers come in different power thresholds. Many cut metal alloys like stainless steel and similar alloys. Good for rapid production. Accuracy from +/- 0.0254mm | Used to support rapid laser cut prototypes and production runs. Like all lasers- system parameters are saved for future production runs. |

| Fiber Laser | Fiber laser technology- more robust than UV or IR, used in laser cutting metal alloys like tungsten, stainless steel, aluminum, brass, copper, and some ceramics. Accuracy from +/- 0.0254mm | Higher power systems ranging from 50 watts to 10k watts or higher. Allows for thicker gauges of alloys to cut up to 10mm or thicker. |

| Quality Inspection Systems | OGP’s (Optical Gaging Products), CMM (Coordinate Measuring Machine, or Visual inspection systems are used in rapid laser cutting manufacturing. | Scheduled calibration is required for these systems to confirm they operate and measure accurately. |

| Quality Management Programs | Industry Standard Quality Management Systems provide the necessary guidelines and practices that critical industries require. Ensures reliability, transparency, traceability and quality of the manufactured parts. | The International Organization for Standardization (ISO-) ISO 9001, the most widely recognized standard within the series, provides a framework for quality management systems that can be applied to any organization, regardless of its size or industry. |

| ISO 9001 | Certification under ISO 9001- allows companies to do business with other industries and companies requiring these standards. Shows where improvements can be made to increase production and quality. | ISO 9000 series of standards, initially published in 1987. Audits for re-certification are done about every two years. |

| ASM 9100 | This certification is focused on the stringent requirements of the aerospace industry. Rapid laser cutting in support of aerospace components will need this. | These standards are essential tools for organizations seeking to improve their quality management systems, enhance customer satisfaction, and achieve operational excellence. Other certifications are required for specific industries. |

| Customer Service Team | Customer Service is vital in communication with the customer from the first inquiry to relaying any changes to the schedule. Creates good relationships with customers. | Staff trained to know what materials and processes work best will help guide the customer to the best decision. |

| Production Team | A cross-trained staff to support on multiple levels. Allows for greater support of rapid laser cutting. | Additional shifts may be used to achieve greater throughput of the work in progress. Cross training gives greater employee satisfaction. |

| Material Handling/Inventory Control | Materials can be a large part of the overall cost. Handling procedures need to be in place and in practice. Having secure and climate-controlled storage keeps materials stable. | Laser service providers can supply many materials, but also welcome customer supplied stock. This can reduce the lead time if stock is readily available and does not need to be ordered. |

The service provided by precision rapid laser cutting providers does involve a well-planned manufacturing system and coordination of all entities in the process. Though each laser manufacturer will have a different system in place, the goal is customer satisfaction brought forth by repeatably providing high quality, communication and cooperation. This is backed by the services and experience of staff who in turn follow the industry certification procedures. The resulting efforts enable rapid laser cut prototypes and production runs to be done with integrity and customer satisfaction.

What Makes a Company Trustworthy for Rapid Laser Cutting?

Laser cutting is a complex process that requires specialized knowledge and equipment. A trustworthy company hosts a team of experienced professionals who understand the intricacies of technology. This expertise, combined with state-of-the-art machinery, ensures that your projects are handled with precision and care. When it comes to rapid laser cutting, time is of the essence. But how can you be sure you’re partnering with a company that can deliver both speed and quality? A trustworthy provider goes beyond just meeting deadlines; they prioritize precision, customer satisfaction, and a commitment to excellence. Trustworthiness is gained by knowing their full capabilities, but also knowing its limitations and therefore will acknowledge the customers’ inquiry but advise them of alternative methods when the project is not a good fit. Becoming a relied upon vendor takes years of service, but the steps to get there must begin on the onset of providing services. To better understand what makes a trustworthy company in rapid laser cutting or other high demand manufacturing, the following list is presented:

- Communication and Customer Service

- Responsiveness: How quickly do they respond to inquiries and requests? Rapid laser cutting is often done for R&D and laser cut prototype support. Responding and quoting same day or within 24, is key.

- Clarity: Is their communication clear and understandable? Being open to online discussions on the project to answer questions and review and concerns.

- Customer Support: Are they available for post-production support and troubleshooting? Communication on challenges and responding to questions post laser processing supports good relationships.

- Flexibility and Customization

- Tailored Solutions: Can they meet your specific design requirements and project needs? Can the company support new challenges with alternative processing and development? This is where many vendors can distinguish themselves from others.

- Versatility: Are they capable of handling various materials and project sizes? Material capability can make or break a project. Having capabilities to handle numerous material types also is a great indication of the technology a laser service provider has. This gives the customer options to seek further support on other projects.

- Technology and Equipment

- Equipment type: Having multiple system types indicates investment for better service by providing customers with manufacturing options. With multiple systems available offers redundancy for manufacturing.

- Support Equipment and Processes: Having structured workflow implementation, designated clean areas and training schedules for staff are just some of the ways rapid laser cutting increases their trustworthiness.

- Quality Assurance and Certification

- Certifications: Companies that are certified under ISO 9001 or other similar industry standards have made a financial investment to abide by these standards. Certifications like ISO 9001 series, support Quality Systems, that in turn provide procedures to ensure the workflow has traceability, transparency, training, and calibration schedules for equipment, to name a few.

- Quality Control Inspection: Critical precision components require that the geometry be confirmed. Companies should be using OGP (Optical gaging Products), CMM (Coordinate Measuring Machines) or other type of certified inspection systems.

- Security and Confidentiality

- NDA’s: Signing an NDA is a binding agreement between the customer and service provider. Having this ability to sign NDAs confirms to customers that their intellectual property will be handled according to the agreement.

- Secure Data Storage and Transmission: For many companies exchange of data needs to be done through a secure encrypted portal. Data is then stored independently and indefinitely for future use and or traceability.

- Competitive Cost and Terms

- Cost Options: Rapid laser cutting services are competitive so being able to offer competitive pricing and options will make the provider stand out. However, the lowest cost is not necessarily the best way to choose a provider. Consider the above-mentioned characteristics that provide repeatability, traceability and certified quality. Some providers have not invested in a QMS or Quality Management System nor have certifications, so there overhead is less, but is the risk worth it?

- Payment Terms: Negotiating on terms and having the flexibility to do so creates a good relationship. Communication early on informs the laser service provider of potential growth with the account that they may be willing to offer terms beyond the norm.

- Experience Counts

- Years of Experience: The quality of manufacturing and performance of service comes with years of experience. The knowledge gained by manufacturing laser cut prototypes or production volume projects takes tens of thousands of hours and multitudes of jobs coming from all factors of industries from the medical field, semiconductor, energy and aerospace are just the very tip of the experience iceberg. To be in service for many years comes with respectable reputations on supporting precision manufacturing.

Trustworthiness and being trustworthy is something many of us in the service industry strive for. It is culmination of taking ownership of one’s duties but assisting too where colleagues may need assistance. This in turn develops into a good formative culture to always be aware of the current processes but also convey when there is perhaps a better way. Customers seeking a reputable service provider of course can learn more online about their potential provider and learn of the capabilities and what insightful information is available. A trustworthy rapid laser cutting service not only should provide a superior product, but also provide technical information to better serve the industry.