Laser Cutting PEEK Service for Precision Parts

PEEK (short for polyether ether ketone) is a type of plastic material within the PAEK (or polyaryletherketone) polymer category. PEEK is a great choice for a variety of precision parts because of its high temperature resistance and long life span.

Ultraviolet (UV) lasers are ideal for cutting PEEK materials. If you are looking for a process that produce precise PEEK parts, our UV Lasers can do this job perfectly. Our UV lasers:

- Have a beam that can hold tight tolerances for extreme precision.

- Can cut complex profiles for your most challenging designs.

- Easily accommodate required cuts with alterations to the computer aided design (CAD) file.

Why work with PEEK materials?

PEEK materials offer outstanding performance in extreme conditions, making these materials some of the best performing thermoplastics in the world. They offer strength, stiffness, long-term fatigue, and other properties that set them apart from other materials.

Extraordinary temperature-, chemical-, and electrical temperature-resistance help PEEK materials endure in harsh conditions. Additionally, they have excellent high-temperature performance, with glass transition temperatures ranging between 289°F – 324°F and melting temperatures between 649°F – 729°F.

PEEK materials also offer very good resistance to chemicals like dilute acid, dilute alkalis, oils and greases, aliphatic hydrocarbons, aromatic hydrocarbons, and halogenated hydrocarbons.

Creep is the deformation observed versus time under a constant application of stress. PEEK Materials have an excellent creep properties and can sustain large stresses over a lifetime of use without significant time-induced extension. They weather time and stress to hold their shape.

Which industries use PEEK materials?

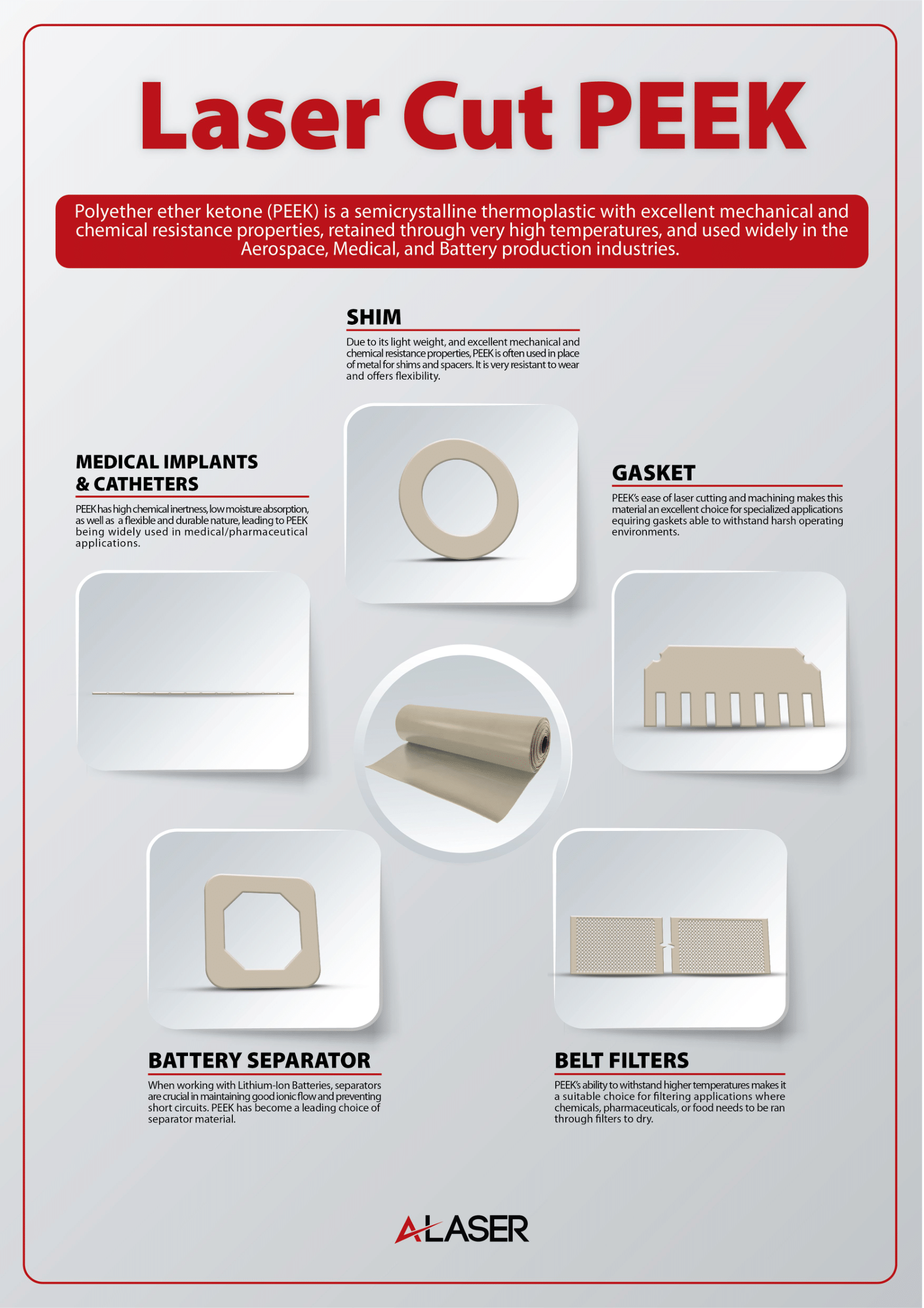

PEEK materials have properties that attract industries like aerospace, automotive, electronics, energy, medical, and semiconductors.

Within the aerospace industry, PEEK is replacing metals in a number of aircraft parts. Cutting PEEK sheets using UV laser can be very beneficial because aircrafts require parts with tight tolerances.

Healthcare is another demanding industry that PEEK materials meet its requirements. PEEK laser cutting produces precision parts that are an excellent fir for healthcare requirements including wear and heat-, electrical-, and chemical-resistance.

Laser cutting for PEEK projects: Expertise from the A-Laser Engineers

Laser cutting PEEK can improve both quality and efficiency. When customers ask to cut PEEK sheets, lasers provide the best software-controlled beam quality and give the engineers designing the drawing the freedom to request tight tolerances and precise cuts.

A-Laser engineers evaluate the project materials and recommend the best system to process them. Then, we work with our customers to develop faster and more efficient processes.

Our engineering team has also developed a process to cut PEEK tubes, in addition to PEEK sheets. There is a lot of science behind developing the process to cut very precise PEEK tubes. A-Laser’s engineering team walks customers through solving challenges when it comes to cutting PEEK materials.

A-Laser experience allows us to quote fast, turn around orders very quickly, and handle large production volume.

Our engineering team allows us to deliver incredible quality, and that’s especially true when we’re processing PEEK sheets. We can recommend the best solution, do the adjustment in the CAD files, and program the laser tooling for the best results. It’s what sets A-Laser apart.