Transforming Materials

Laser cutting supplies from a laser service provider’s perspective has two distinct meanings. If you ever have walked into a custom shop of wood carvings or perhaps glass blowing, you will see the mastery of artists and creators transforming the wood and glass into outstanding examples of carving and glass sculptures. The knowledge of the tools each creator has, and the skills used comes with many years of experience and finesse of each material. The media in which they devote time and skill to needs to be acquired, wood is grown, cut down and planned perhaps. Raw glass comes from silica and other added materials. When heated in a furnace the particles fuse to form glass. In both disciplines, the materials are part of the process and need to be supplied. The same is true for

laser manufacturing and any other industries in the business of manufacturing in which raw materials are the basis in which all products are made from. The other aspect is once the wheels are moving and all areas of a manufacturing process are in place, then the supplied vendor becomes the supplier. There is a series of steps and streams of supporting suppliers to keep the production lines moving along and receiving payment for their part of the process. This is how manufacturing works in basic terms. In the inner details, manufacturers like laser precision component companies will have their set of suppliers for raw materials.

An Assortment of Material Suppliers

Manufacturing precision laser cut parts relies on materials. The technology uses existing metal alloys and non-metallics to produce simple washers to intricate and complex designs. To utilize the laser technology to their upmost capabilities, laser service providers sustain relationships with multiple sources from exotic metals to plastics. It takes much coordination and vetting of potential suppliers because much of the work being processed with laser technology is governed by outside and internal auditing of the production process. The medical device industry requires that suppliers of any medical production stream have documented procedures in place. In this case, “what is the material, and can you show it is what you say it is”. Projects supporting defense and critical use projects will have similar demands for transparency and work only with companies certified under ISO-9001 series or other industry certifications.. Once all is in place, you would see in supply rooms materials of varying thicknesses and grades for:

- Polyimides

- Grafoil and Graphene

- Mylar

- FR4

- Ceramic

- PEEK

- Adhesives- acrylic and silicon based

- Stainless Steel- grades such as 304, 16-6, 17-7,

- Nitinol

- Aluminum

- Tungsten

- Nickel

- Titanium

- Copper

- Brass

- Silicon based Rubber

- Nitrile Based Rubber

The list goes on for many other metallic and non-metallic materials. Keeping them stored in a secure and climate-controlled environment ensures the stability of unprocessed materials. Many companies require certified materials to be in conformance within a QMS or quality Management System.

From Supplied to Supplier

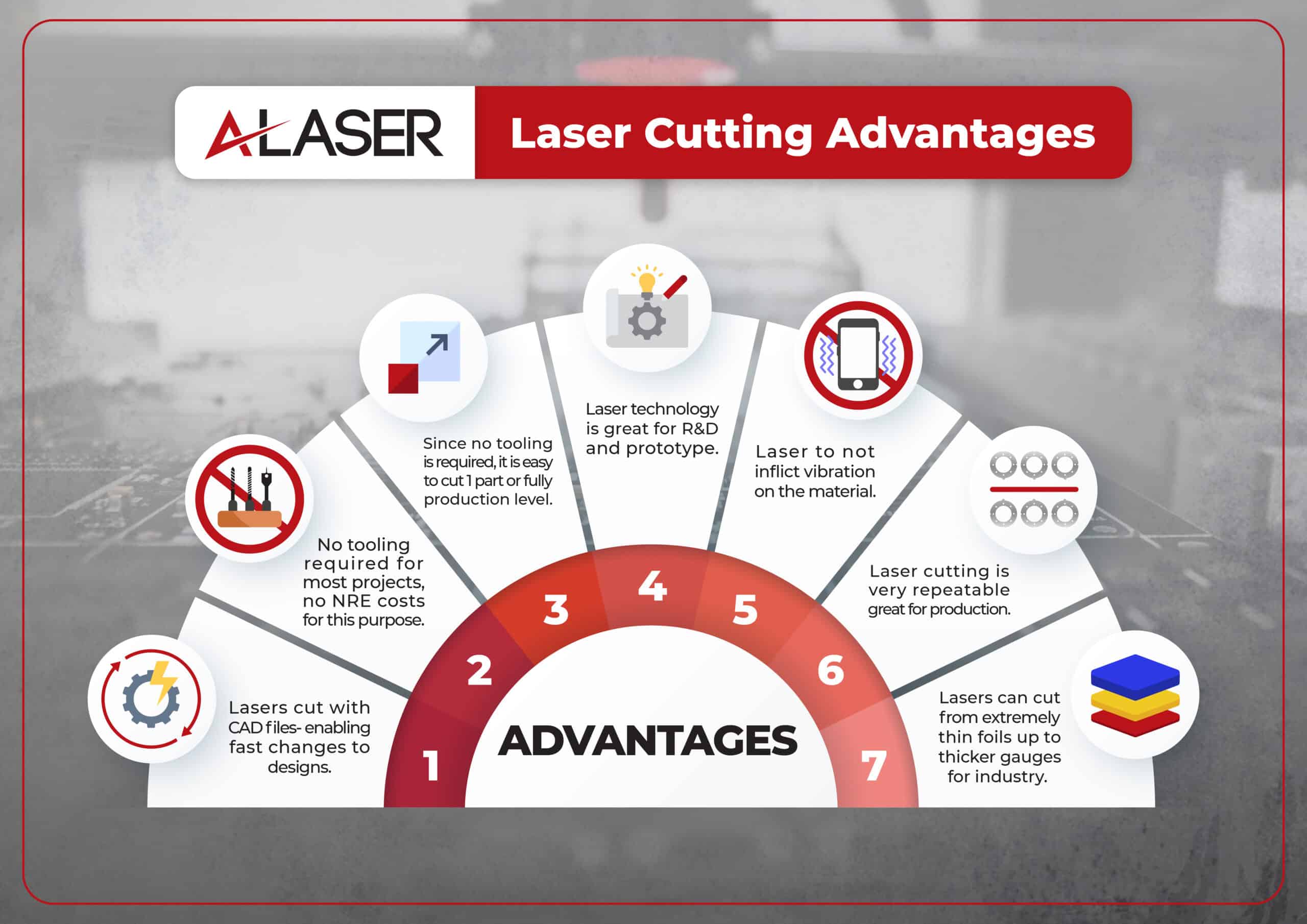

As a manufacturer, becoming a preferred supplier is a great accomplishment and an even greater motivation to seek more opportunities. Thinking of laser cutting supplies from this perspective is rewarding because it means the knowledge and technical capabilities that a laser service provider uses, is affirmed and qualified as a volume supplier. Production volumes for critical use medical devices to sensors in automobiles to shims and gaskets, are in part supported by laser technology. This occurs because one of the attributes of laser manufacturing is the stability in the process. To be successful in any manufacturing sector means quality and capabilities are combined. The following information gives some insight into how laser manufacturing has become a go to supplier.

Recognition Of New Materials

Manufacturers need to be able to recognize trends in the industry that can be beneficial to their customers. This ability to match certain characteristics of a material for potential customer use can add confidence, integrity and build a great relationship. Knowing the traits like stability in high heat environments or have light blocking characteristics, can help a customer decide if a material is right for the job. Laser cutting supplies assist in many stages of product design from conceptual in understanding the parameters and what the challenge is and working with customers in the early R&D and prototype stages. Furthermore, being a supplier and having built up relationships with raw sources, allows for collaboration when seeking a specific need for a metal or non-metallic. It is a continuous circle of communication and support that makes laser cutting supplies and similar manufacturing, a process of ongoing collaboration.