Laser Cutting Gold

At A-Laser, we specialize in industrial gold laser cutting. Industrial gold laser cutting and laser cutting gold jewelry are both processes that use a laser to cut through a material. However, there are some key differences between the two.

- Type of laser: Industrial gold laser cutting typically uses a CO2 or UV laser, while laser cutting gold jewelry typically uses a fiber laser.

- Quality of cut: Industrial gold laser cutting generally results in a rougher, more industrial grade cut, while laser cutting gold jewelry produces a smoother, more precise cut.

- Material thickness: Industrial gold laser cutting can cut through thicker materials than laser cutting gold jewelry, which is typically limited to cutting through thin sheets of gold.

- Purpose: Industrial gold laser cutting is used for large-scale production and manufacturing, while laser cutting gold jewelry is used for creating intricate designs and shapes in small quantities.

- Cost: Industrial gold laser cutting is generally less expensive than laser cutting gold jewelry due to the higher production volume and lower precision requirements.

Our team has extensive experience with industrial laser processing a variety of metallic materials, including pure gold. UV laser systems are an excellent solution to processing this precious metal, whether it’s via laser ablation or laser etching. Pure gold material is often too thin and too delicate to process on other laser systems.

Processing gold in the form of soft, gold foil requires awareness and prevention of tearing, which it is prone to do. When dealing with small gold part sizes, gold can burn along the edges. UV lasers successfully tackle all these challenges and ensure cleaner edges compared to other processing methods. The UV laser offers freedom in programming and the ability to optimize parameters for a tighter etch size, depth, and quality. Laser cutting gold on UV lasers is a cost- and time-effective manufacturing method that provides freedom of design and iteration which is deal for short runs, extreme precision, and consistency.

Gold offers numerous advantageous qualities that benefit a variety of industries. Gold’s corrosion resistance, high electrical conductivity, enhanced durability, and excellent heat protection make it ideal for applications in medical, aerospace, electronics, and more.

The control and adaptability of the UV laser is perfect for projects involving gold films. For example, 5 mil Kapton film can be coated with a very thin layer of gold on both top and bottom sides. With the depth control the UV lasers offer, our team can etch off the gold in certain areas to break the connection on the surfaces, creating traces to connect only specific points on the sheet. This can be done with extreme precision and extremely small traces on both the top and bottom sides of each sheet. These delicate parts must be handled properly to guarantee damage-free processing. Exposing the Kapton produces areas that are electrically insulating, opposite of the gold traces.

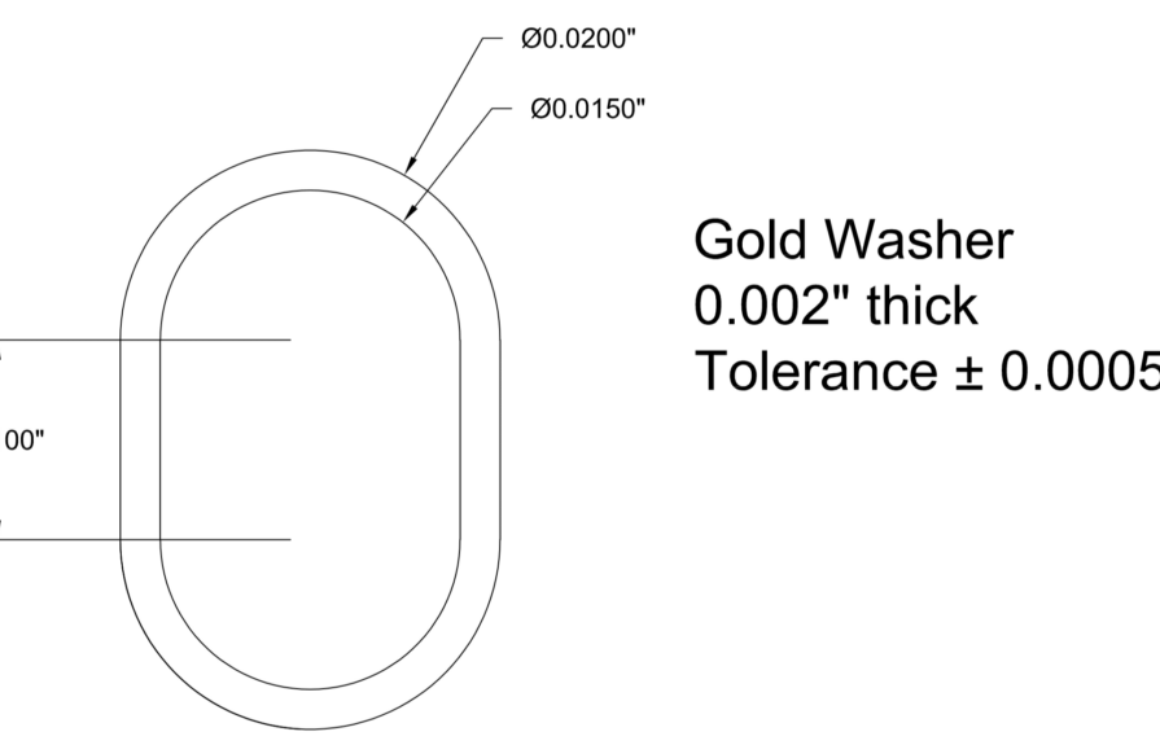

We recently completed a project for very thin, gold washers. The pure gold had a thickness of only 0.002” (0.05mm). The washers were ~0.48mm OD, 0.38mm ID. For processing material this thin, a UV laser is hard to beat. While pure gold is easy to process for our UV lasers, brazing alloys are also able to be processed. Brazing alloys are a combination of metals melted together, often including gold, nickel, and copper.

Aside from laser cutting gold, our laser systems are well-suited for silver, copper, stainless steel, nickel, and more.