Laser Cut Ultem Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

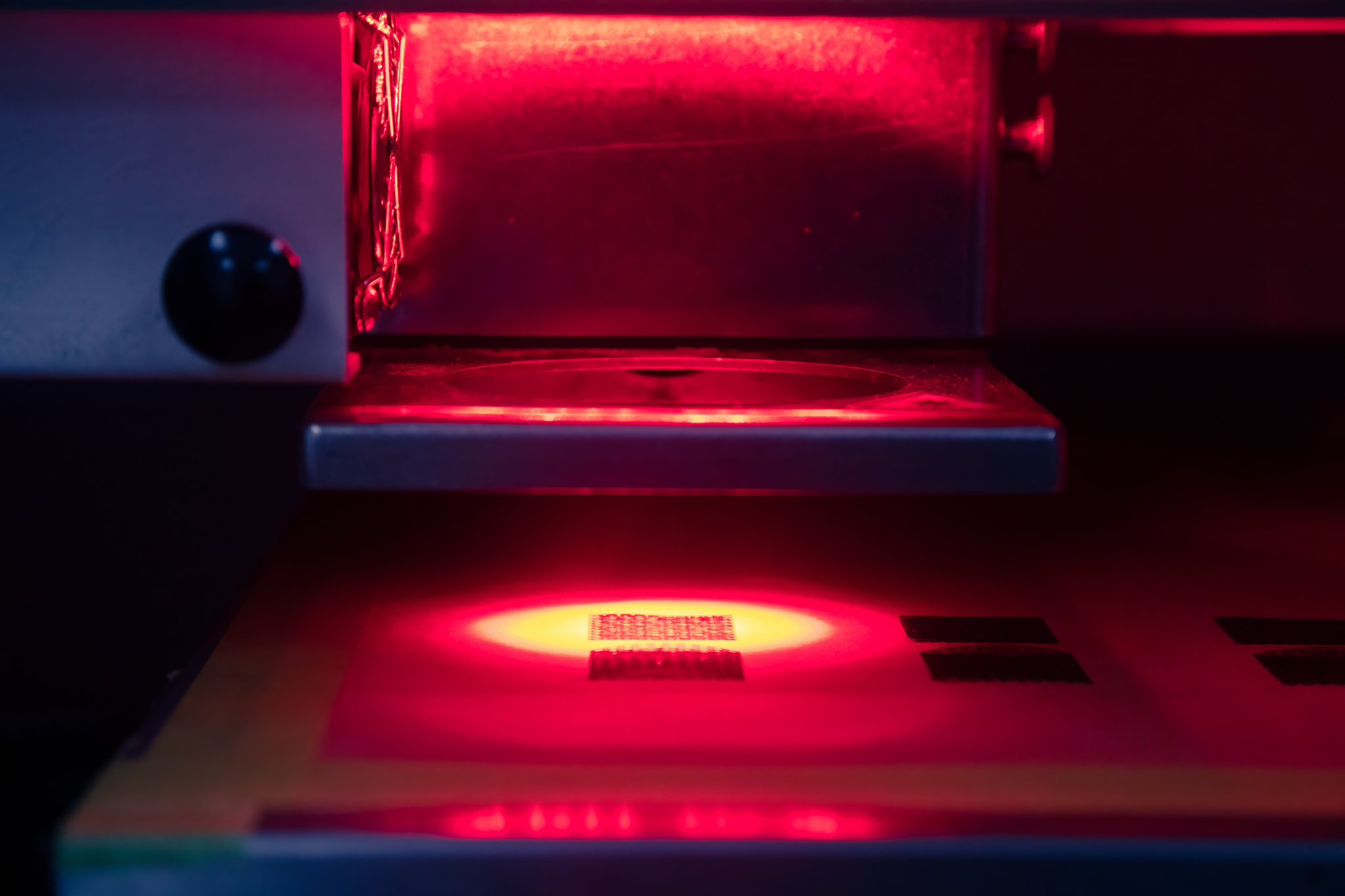

Ultem, the trade name for polyetherimide,(PEI), is known for having excellent thermal stability, mechanical strength, and chemical resistance. When used for precision manufacturing, Ultem stands out for its ability to maintain tight tolerances and deliver superior edge quality, particularly when processed with advanced laser cutting technologies like UV or femtosecond lasers. These properties make it a preferred for applications, where reliability, accuracy, and miniaturization are critical. To help understand better the relationship between Ultem material and precision laser manufacturing, the following questions and answers are provided below.

Thinking Tolerance

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Ultem?

With advanced laser systems (such as UV or femtosecond lasers), tolerances as tight as +/- 1 mil can be maintained when cutting Ultem. This is especially achievable on thinner sheets (<0.060″) with proper fixturing and environmental control. There will be exceptions as with all manufacturing methods, that make the tolerance threshold larger, such as the complexity of the cut and the thickness of the Ultem.

Different Manufacturing Techniques

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Ultem?

This comparison of manufacturing techniques does not conclude that one is much better than the other, but it is a generality of these methods when Ultem material is used.

| Method | Pros | Cons |

|---|---|---|

| Laser Cutting | Extremely tight tolerances, clean edges, no tooling, ideal for thin materials and for prototyping. | Potential for heat-affected zones if not optimized. Can be slower than other methods. |

| Die-Cutting | Fast and cost-effective for high-volume runs. | Less precise, it requires tooling, not suited for intricate or thick parts. Not used generally for R&D and prototypes. |

| Waterjet Cutting | thermal distortion, works for thicker Ultem. | Lower edge precision, slower, risk of edge swelling on softer plastics. |

| CNC Machining | Precise and good for 3D features. | Slower, potential tool wear, not ideal for thin parts or tight radii. |

Laser cutting of Ultem is a great technology to use when the designed components are for 2D profiles and within thickness ranges of the laser systems. For thicker material projects or parts of 3 or 4 axis, CNC machining or waterjet will be options to use. For all methods, there are benefits of use and the selection of one over the other is dependent on the factors involved for each project. Consultation with potential service providers will give you valuable insight to the technology that is best for your project development.

Focused On the Edge

What Edge Quality Can Be Expected When Laser Cutting Ultem? Are Burrs or Heat-Affected Zones (HAZ) Present?

Laser cutting Ultem produces lean, smooth edges with minimal burring and results in highly defined contours, especially with UV lasers, although slight discoloration or charring may occur if parameters are not optimized. Using UV (ultraviolet) or femtosecond lasers provide the highest edge quality with minimal thermal impact.

Regarding burrs, they are typically absent with laser cutting due to the non-contact process. HAZ (Heat Affected Zone) is minimal when using UV or femtosecond lasers. HAZ can be reduced by optimizing speed and pulse settings, laser passes and other parameters.

Character Considerations

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Ultem?

- Reflectivity: Ultem has low reflectivity in UV and IR ranges — favorable for laser absorption.

- Softness: Moderately soft, but not rubbery; retains clean cuts without deformation.

- Thermal Conductivity: Low thermal conductivity means heat can concentrate — requires fast, precise laser pulsing to avoid charring or HAZ. The laser parameters are adjusted to prevent excessive HAZ.

Here’s the Value

What Are the Benefits to Laser Cutting Ultem?

- Tight Tolerances & Precision:

Laser cutting can achieve tolerances as tight as ±0.001 mil on Ultem, ideal for high-precision components in electronics, aerospace, and medical applications. - No Tooling Required:

Unlike die-cutting or CNC machining, laser cutting doesn’t require hard tooling. This reduces setup time, lowers production costs, and enables fast design changes. - Intricate Geometries & Fine Features:

Lasers can produce very small holes, tight radii, and detailed contours not possible with mechanical methods, making it ideal for connectors, insulators, and other tight-tolerance parts. - Material Efficiency:

The narrow kerf of the laser reduces material waste, optimizing sheet yield.

Closing Notes

The properties of Ultem are well-suited for laser cutting, especially with short-pulse or UV systems, where edge definition and tolerance control remain high. These advantages make laser cutting one of the most effective fabrication methods for Ultem, particularly in industries requiring tight dimensional control and high-performance polymers. The decision to use laser technology often will be made from the factors of the project that lean towards the non-contact process.