Laser Cut Polypropylene Film Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

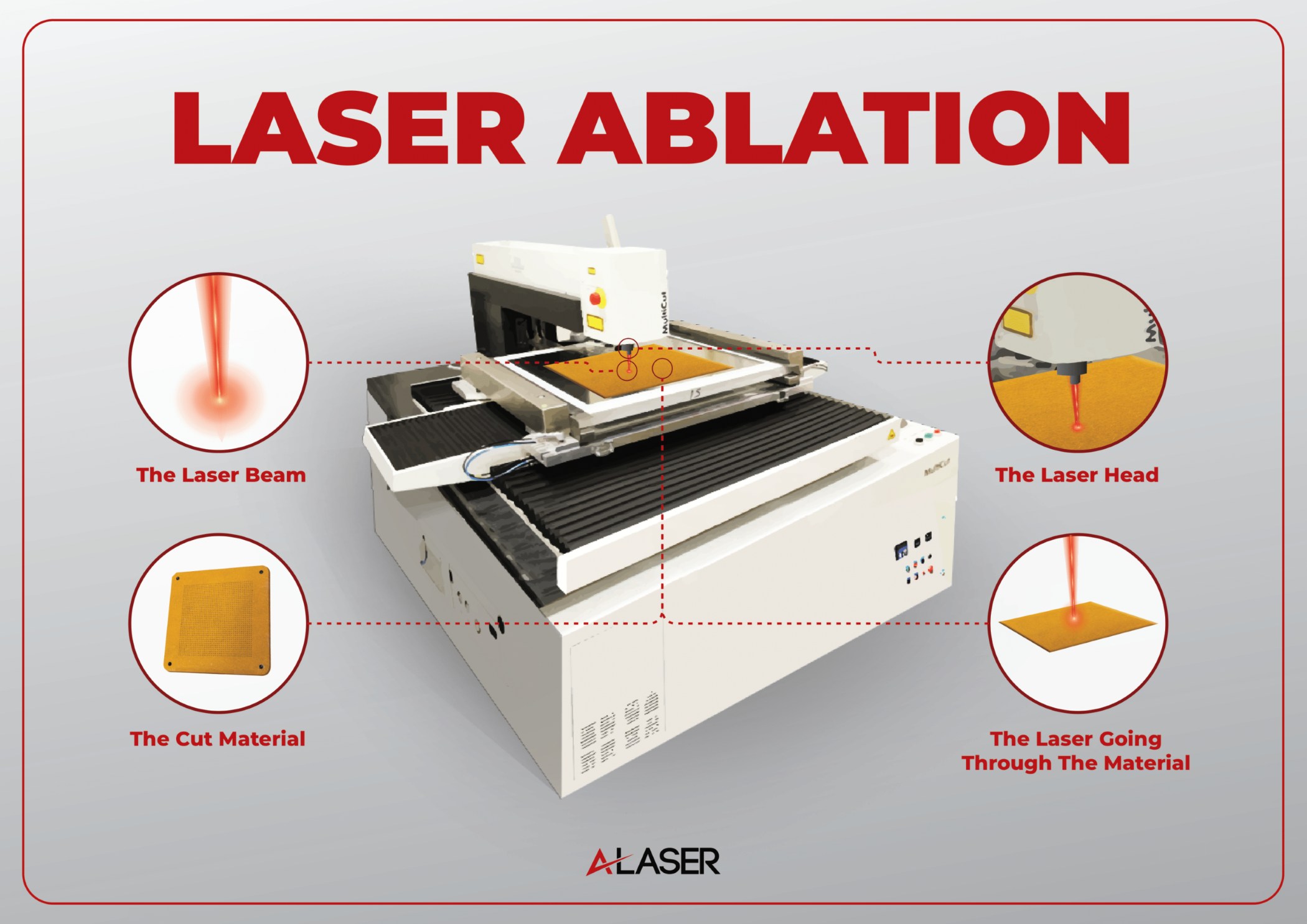

Polypropylene film has evolved from a simple packaging material into a precision-engineered medium for advanced manufacturing. When processed with UV laser cutting technology, this lightweight yet durable polymer can be transformed into high accuracy 2D parts and components with exceptionally clean edges and tight tolerances. The ultraviolet wavelength interacts efficiently with the film’s molecular structure, enabling cuts that are sharp, burr-free which is a level of precision difficult to achieve with mechanical methods. This capability makes polypropylene film a preferred choice for industries producing microfluidic layers, electrical insulators, optical components, and precision laminations, where dimensional stability and material integrity are critical. The following Q&A explores how the properties of polypropylene film and the advantages of UV laser processing converge to enable such precise and reliable results.

Anticipated Tolerance

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Polypropylene Film?

When laser cutting polypropylene film, manufacturers can typically achieve tolerances in the range of +/- 1 mil to +/- 2 mils, with the exact precision influenced by the geometry’s complexity and the film’s thickness. Holding such tight tolerances is essential for industries like microfluidics, electronics, and optics, where even slight variations can impact performance, reliability, and product integration. In developing new technologies, precise control over dimensions ensures that components fit seamlessly together, function as intended, and meet stringent quality standards. This level of accuracy is especially important for applications that demand consistent material properties and flawless edge quality to support innovation and maintain competitiveness in advanced manufacturing sectors.

Manufacturing Versus Manufacturing

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Polypropylene Film?

When cutting polypropylene film, laser technology, especially UV laser cutting, offers a distinct performance advantage over traditional methods like die-cutting, waterjet, or CNC machining resulting in exceptionally clean edges, fine detail, and consistent tolerances even in thin or multilayer polypropylene constructions. However, laser cutting technology is not the only solution. Depending on a project’s specific factors, others methods be a better fit.

| Manufacturing Process | Advantages | Limitations |

|---|---|---|

| Laser Cutting | Extremely fine features, tight tolerance, no stress, no tooling or extensive set-up. | Slower for cutting thicker materials, needs optimization to prevent HAZ (Heat Affected Zones) |

| Die-Cutting | Great for high volume of simpler shapes and cost is low once tooling is made. | Risk of edge compression, limited details, design changes require new tooling. |

| Waterjet Cutting | No heat affected zones, good for cutting thicker materials. | Water can damage materials, especially laminate. Not good for thinner materials. |

| CNC Machining | Accurate for thicker materials and 3D designs. | Not suitable for thin films and can add stress to substrates. |

In essence, UV laser cutting delivers unmatched precision, cleanliness, and design flexibility for polypropylene film applications, making it the preferred choice when detail, consistency, and non-contact processing are key priorities.

Polypropylene Film Distinctive Qualities

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Polypropylene Film?

Laser cutting polypropylene film presents distinct challenges due to its unique material properties. Achieving precise, clean cuts require careful process optimization tailored to PP’s behavior under laser exposure.

Material-Specific Behaviors

- Softness: PP’s softness makes it susceptible to melting and material flow when exposed to concentrated laser energy.

- Low Thermal Conductivity: Heat from the laser stays localized, increasing the risk of thermal deformation and making it harder for the material to dissipate heat quickly.

Risks During Laser Cutting

- Burr Formation: Residual heat can cause melting, resulting in slightly raised edges or burrs that compromise edge quality.

- Thermal Deformation: Localized heat may warp the film, impacting dimensional accuracy.

- Heat-Affected Zone (HAZ): Slow heat dissipation can cause a broader HAZ, making tight tolerance control (such as +/- 1 mil) challenging.

Actionable Solutions for Process Optimization

- High-Speed, Low-Power Settings: Increase cutting speed and reduce laser power to minimize heat buildup and prevent excessive melting.

- Multiple Laser Passes: Used in conjunction with laser speed and power to fine tune the edge quality result.

- Regular Calibration: Frequently calibrate the laser system to maintain consistent energy delivery and precise cut tolerances.

Tailoring laser cutting parameters to polypropylene’s softness and low thermal conductivity is essential for achieving clean edges and precise tolerances. By implementing high-speed, low-power settings, using assist gases, and maintaining regular calibration, manufacturing engineers and technical operators can overcome PP’s material-specific challenges and improve cut quality.

Edge Quality Expectations

What Edge Quality Can Be Expected When Laser Cutting Polypropylene Film? Are Burrs or Heat-Affected Zones (HAZ) Present?

By making the adjustments to the laser parameters or “laser tool”, you can expect a very well-defined cut edge. Laser technology is a thermal process so some discoloration may occur in the form of carbon residue. Post processing may be used if acceptable for the application to remove the carbon with an alcohol or IPA wipe.

Main Points to Remember

What Are the Benefits of Laser Cutting Polypropylene Films?

In summary, laser cutting polypropylene film offers numerous advantages, including clean and precise edges, minimal material distortion, and the ability to customize cuts for complex designs. This process also reduces the need for mechanical tooling and post-processing, making it an efficient and cost-effective solution for various applications in manufacturing and product development.