Laser Cut Nomex 410 Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Nomex, known for its exceptional heat and flame resistance, is a trademark of Dupont Corporation. First developed back in the mid 1960’s, the use of Nomex, a synthetic meta-aramid fiber material, grew rapidly in the 1970’s for use in protective apparel for fire fighters, pilots, and those in need of protection. It was also used in applications for light weight structural components, insulation, and filtration units in high heat environments. Over the proceeding decades new developments have been made and “Nomex” has become the umbrella name for other specialized Nomex products, like Nomex 410. Nomex 410 is a high-performance insulation paper, which shares the basic properties of heat and flame resistance, but not suitable for protective gear. Nomex 410 is available in multiple thicknesses and a great fit when laser cut. A-Laser’s experience in cutting Nomex 410 has become an opportunity for those seeking to utilize the precision of laser technology and properties of this synthetic paper. Additional insight into Nomex 410 and laser cutting is provided in the following Q&A.

Manufacturing Comparison

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Nomex 410?

Often the question of comparing laser cutting to other manufacturing methods is asked and we are happy to discuss available options. Laser cutting of thin 2D parts is the primary function of this method so comparison to others does not fully show each method’s full capabilities, as project details vary greatly. The following table is a general comparison of manufacturing flat Nomex 410 components.

| Cutting Method | Comparison of Laser Technology | Key Characteristics for Nomex 410 |

|---|---|---|

| Laser Cutting | A great choice for precision and speed on thin materials. Generally faster than waterjet and CNC for 2D parts. More precise than die-cutting or waterjet. | High precision and ability to cut intricate details without tool wear. Creates clean, sealed edges. May cause a slight heat-affected zone (HAZ) or discoloration at the cut edge. |

| Die-Cutting | Fastest for high-volume production once the initial die is made. Less precise for complex shapes or small features. Has high initial tooling cost but lowest per-part cost in high volume. | Excellent for mass production of simple, uniform parts. Mechanical contact can lead to fraying. Requires a dedicated tool (die) for each shape. |

| Waterjet Cutting | Slower than laser cutting for thin material. No heat-affected zone (HAZ). Less precise than laser, especially for thin material, and may introduce moisture. | No heat damage, preserving the material's integrity. Good for thicker aramid-based composites or if the HAZ from laser cutting is unacceptable. |

| CNC Machining | Slower than both laser and waterjet for simple 2D profiles. Can achieve high precision but primarily used for thicker material or 3D geometries. | Typically overkill and too slow for thin Nomex 410 paper/sheet. Mechanical contact can cause fraying, tearing, or burrs. |

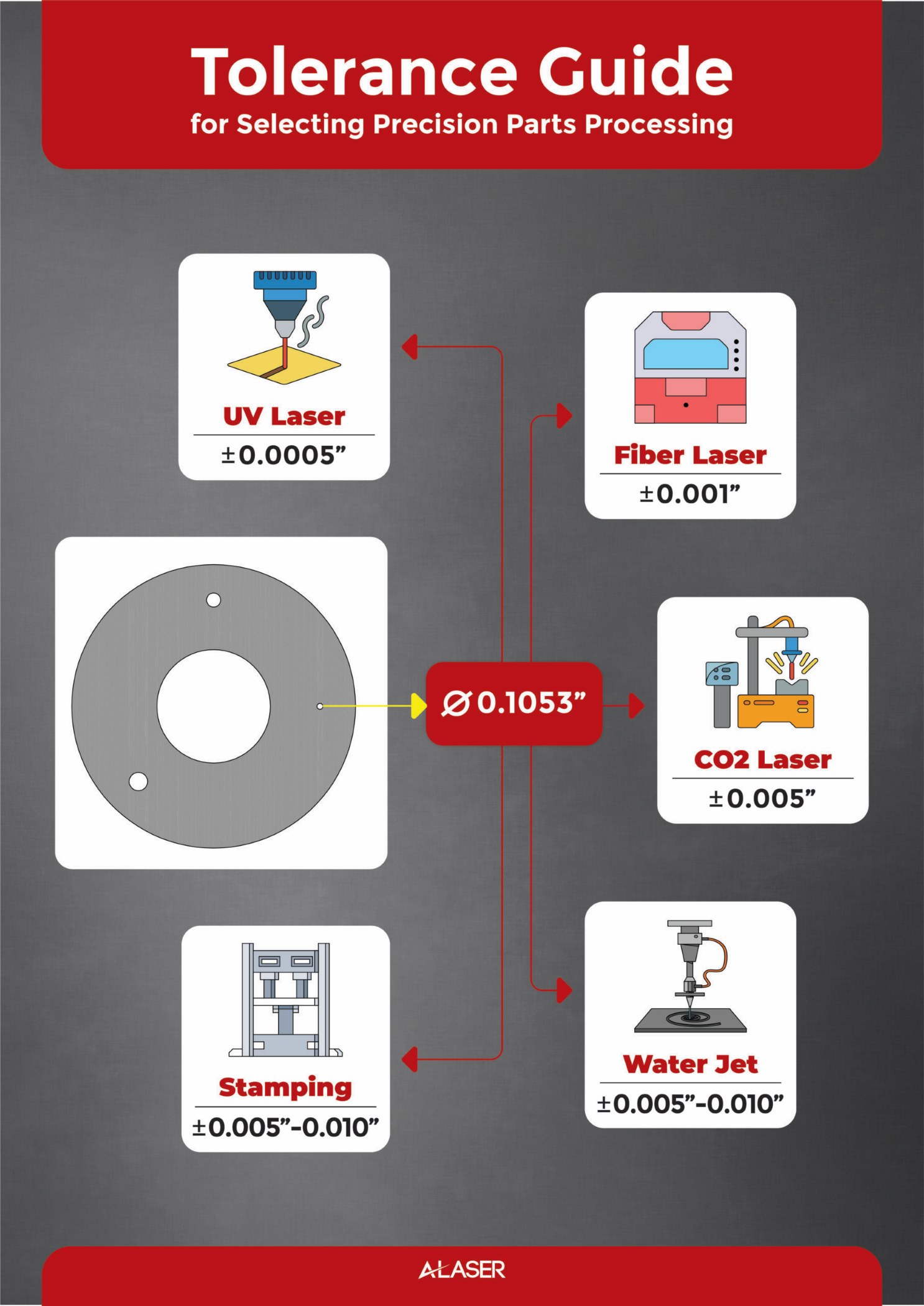

Tale of Tolerance

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Nomex 410?

Using our UV (Ultraviolet) laser systems, you can expect standard tolerances to be held within +/- 1mil. For thinner Nomex 410 potentially the tolerance will be +/- .5 mil. This level of precision significantly surpasses traditional die-cutting and is comparable to or better than waterjet and CNC milling on thin aramid paper. Thicker Nomex 410 sheets and complex shapes, over a larger area may result in a +/- 2mils.

Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Nomex 410?

Here is how the characteristics of Nomex 410 can potentially affect the laser cut edge quality:

Low Reflectivity: Absorbs light instead of bouncing it back — ideal for clean, precise laser cuts.

- Absorbs UV laser energy efficiently, minimizing scatter and ensuring precise energy delivery.

- Results in clean, sharp edges with minimal taper.

Soft, Fibrous Structure: Made of tightly packed fibers that give flexibility and strength without brittleness.

- Can slightly fray or fuzz at the edges if laser parameters are not optimized.

- Parameter adjustments carefully control of pulse energy and cutting speed to prevent fiber lift or discoloration.

Low Thermal Conductivity: Doesn’t easily transfer heat — minimizing burn marks or heat damage during cutting.

- Limits heat spread, keeping the cut zone localized and preventing warping.

- Produces smooth edges with virtually no Heat-Affected Zone (HAZ), keeping laser parameters at optimum settings.

Dimensional Stability: Keeps its shape and size even under heat or stress — ensuring tight tolerances.

- Nomex 410 maintains its form under moderate heat, supporting tight tolerance control.

- Typically enables tolerances within ±0.001–0.002 in (depending on thickness and laser type).

Dielectric Nature: Resists electricity — perfect for insulating and electronic applications.

- Prevents melting or reflow seen in thermoplastics, preserving crisp edge geometry.

- Enhances repeatability for electrical and insulation components.

Because Nomex 410 absorbs laser energy efficiently, resists heat spread, and maintains its structure under cutting conditions, it delivers exceptionally clean edges and tight tolerances that make it ideal for precision insulation and electrical component fabrication.

Quality Of the Cut Edge

What Edge Quality Can Be Expected When Laser Cutting Nomex 410? Are Burrs or Heat-Affected Zones (HAZ) Present?

When laser cutting Nomex 410, the results are impressively clean and consistent, which is a hallmark of precision laser manufacturing. The material’s unique aramid composition, ( a class of strong, heat-resistant synthetic polymers), and low thermal conductivity allow the laser to make crisp, well-defined cuts without charring or distortion. Unlike metals or thermoplastics, Nomex 410 does not produce burrs, melted edges, or significant Heat-Affected Zones (HAZ); instead, the edges remain smooth, uniform, and ready for use in applications needing electrical and insulation properties. This combination of precision and cleanliness makes laser cutting the preferred method for achieving fine detail and reliable fit in parts made from Nomex 410.

Summary

What Are the Benefits of Laser Cutting Nomex 410?

Keep in mind the following:

- Aramid materials Nomex 410 don’t melt easily.

- They maintain strength at high temperatures.

- They resist burning, tearing, and shrinking under heat or stress.

Utilizing laser cutting services, these components will not only have the properties that Nomex 410 offers but also be precisely made in quality that is unmatched from many other methods. The rapid nature of product development is supported by laser cutting machines that can produce prototypes without tooling costs and extensive set-up time. Laser manufacturing is unique in that many systems can cut a multitude of materials supporting even greater sectors of industrial needs within one manufacturing environment. For further information about how we can take your project forward, please feel to contact us.