Laser Cut Mu-Metal Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

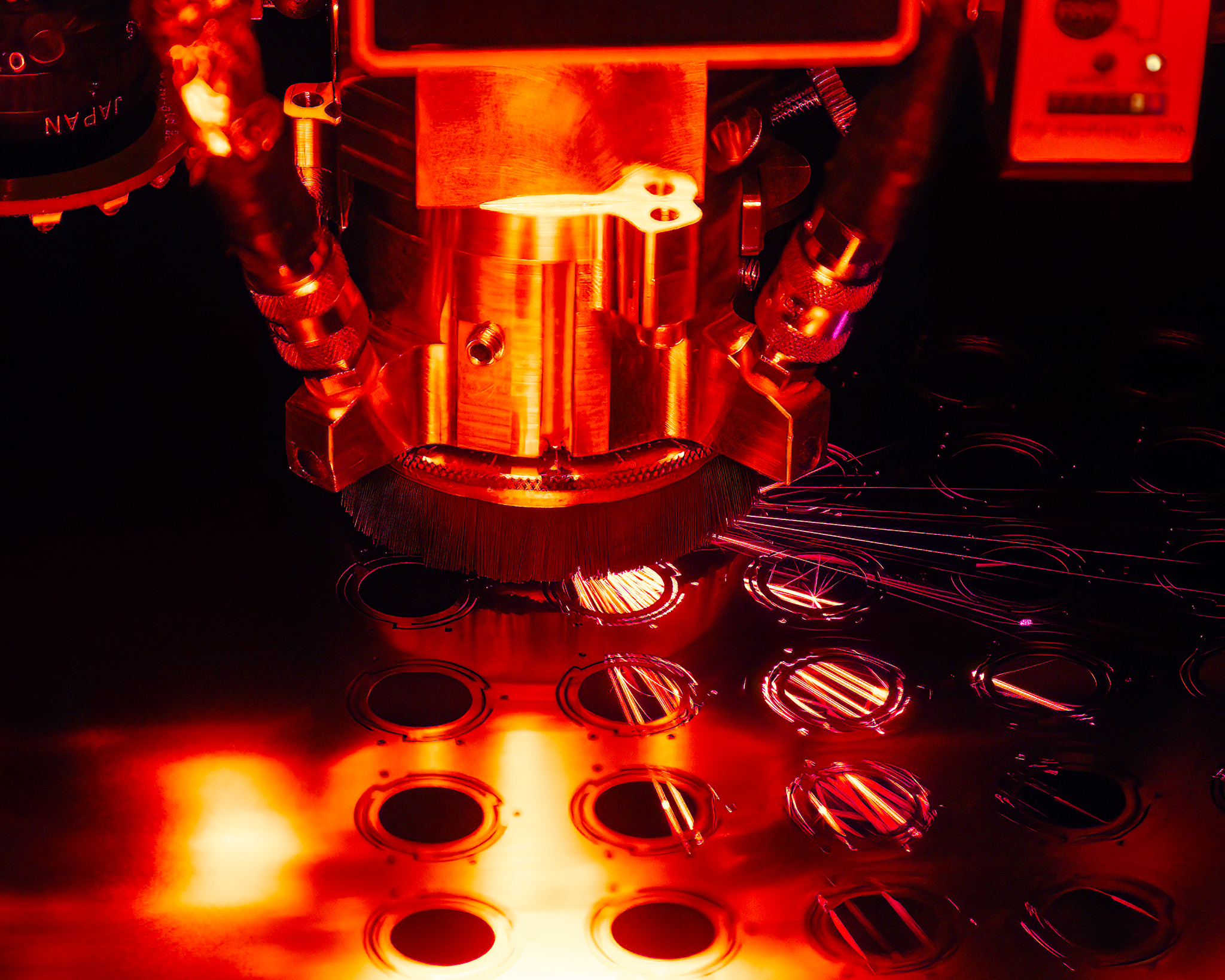

Mu-metal is valued for its superior low-frequency magnetic shielding due to its composition of about 75-80% nickel, with iron and traces of molybdenum (or chromium) and sometimes copper. Its ductility allows it to be formed into thin sheets or foils. Precision laser cutting is commonly used to fabricate custom shapes and intricate components for applications in hard disk drives, electronic enclosures, MRI machines, scientific instruments, electron microscopes, and cathode ray tubes. Laser cutting enables tight tolerances and minimal stress, making it ideal for detailed magnetic shielding requirements. For further details about Mu-metal and its laser-cutting process, refer to the following Q&A, and feel free to reach out with any additional questions.

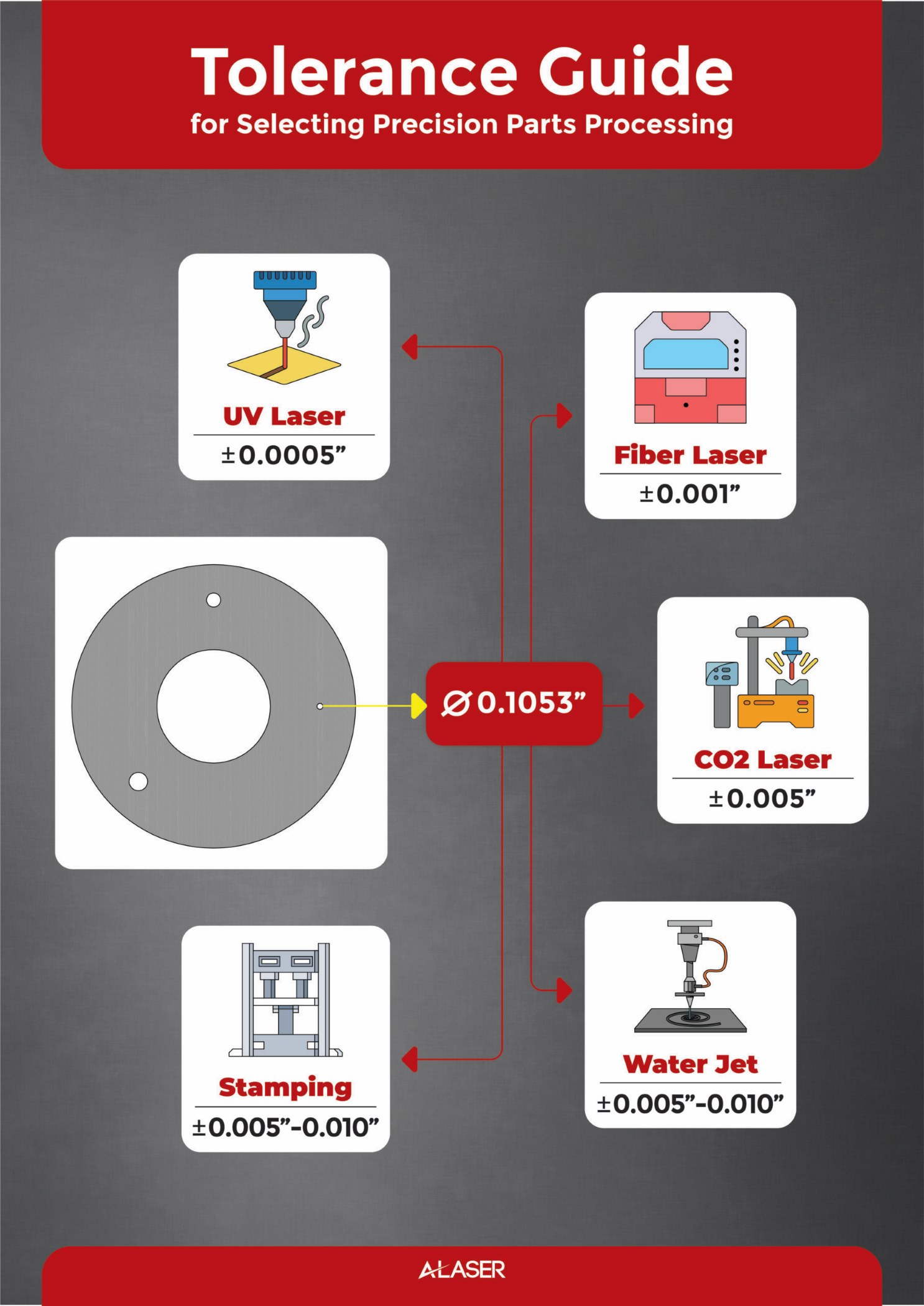

Tolerance Expectations

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Mu-metal?

Laser cutting of thin foils and sheets is done currently at A-laser by two system types, UV (ultraviolet) and Fiber lasers. With often critical nature to projects using Mu-metal, the tolerances are often held to a +/- .5 mil to +/- 1mil. Thicker sheets of Mu-metal from about 10mils to 20 mils may see the expected tolerance at +/- 2mils.

Manufacturing Methods

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Mu-metal?

Mu-metal (a high-permeability nickel-iron alloy) is extremely sensitive to mechanical stress (strain), as stress dramatically reduces its ability to shield magnetic fields. Therefore, the choice of cutting method is critical, with the goal being to minimize stress and the resultant work-hardening and grain-structure distortion.

| Method | Key Advantage for Mu-metal | Disadvantage/Limitation | Ideal Application for Mu-metal |

|---|---|---|---|

| Laser Cutting | Highest Precision and speed for thin-to-medium sheets. Excellent for intricate, custom profiles and small features. | Thermal Process introduces a small Heat-Affected Zone (HAZ) at the cut edge. This heat/stress must be fully removed by post-fabrication annealing. | Best for highly complex, small magnetic shields for electronic sensors, audio transformers, other sensitive devices. |

| Die-Cutting | Extremely Fast and Most Cost-Effective for high-volume production of simple forms. | Highest Mechanical Stress on the material. Requires significant post-fabrication annealing to restore permeability. Tooling costs are very high. | Mass-produced, simple shapes like washers, or bent shields. |

| Waterjet Cutting | Non-Thermal Process that introduces virtually no heat or HAZ. Lowest amount of internal stress. | Generally Slower than laser cutting for thin material. Lower overall precision and wider kerf (cut width) than laser cutting. | Mass-produced, simple shapes like washers, or shields for consumer electronics. |

| CNC Machining | Only method for very thick plates or solid bar stock to create three-dimensional (3D) forms. | Slow and Expensive for simple 2D shapes. Introduces significant mechanical stress and surface friction damage. | Structural or heavy-duty shields where the component is made from a thick block rather than sheet metal. |

Nearly all Mu-metal parts must undergo final annealing in pure hydrogen at high temperatures to relieve internal stresses and boost magnetic permeability. Skipping this step significantly reduces shielding effectiveness.

The Character of Mu-metal

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Mu-metal?

Influence on Edge Quality and Tolerance

Laser cutting Mu-metal is greatly affected by the alloy’s characteristics. Its high nickel content makes it soft and ductile, prone to smearing and burrs when mechanically sheared, but laser cutting helps reduce these effects and delivers cleaner edges.

The material’s low thermal conductivity causes heat from the laser to build up at the cut, creating a localized Heat-Affected Zone (HAZ) that hardens the edge. This work-hardening reduces magnetic permeability, which is crucial for shielding and must be restored through high-temperature annealing after cutting.

Reflectivity and Cutting Efficiency

Mu-metal’s dark color and low reflectivity are ideal for fiber laser cutting, ensuring efficient energy absorption, faster cutting, and precise tolerances of complex shapes, so long as the sheet thickness matches the laser’s range.

Managing Thermal Stress

The main challenge is thermal stress from the laser. Balancing power and speed help minimize edge degradation, but final annealing remains necessary to recover magnetic properties and ensure effective shielding.

Expected Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Mu-metal? Are Burrs or Heat-Affected Zones (HAZ) Present?

Effective management of thermal stress is essential to achieving optimal edge quality in laser-cut Mu-metal. In typical metal cutting operations, burr formation is a common occurrence, though these are usually limited to micro-burrs. After the laser cutting process, these small burrs can be addressed through various post-processing techniques.

- Mechanical Sanding: Micro-burrs are often removed using fine grit sandpaper, typically in the range of 1000 to 2000 grit. This method helps to smooth the edges and improve the overall finish.

- Chemical or Tumble Deburring: These processes offer alternative approaches for burr removal, utilizing chemical reactions or abrasive tumbling to clean the cut edges efficiently.

- Electro-polishing: Discoloration that may occur along the cut edge can be effectively eliminated with electro-polishing, resulting in a clean and visually appealing finish.

The choice of post-processing method depends on the specific requirements of each project. Recommendations for suitable techniques will be provided based on the unique characteristics and needs of your application.

Key Takeaways

What Are the Benefits of Laser Cutting Mu-metal?

- Rapid prototyping: Laser cutting allows for quick turnaround on prototypes, enabling customers to move efficiently from design to production.

- Design cut versatility: The technology supports a wide range of intricate shapes and patterns, making it ideal for complex or custom designs.

- Minimal set-up time: Little to no tooling is required, reducing lead times and allowing for faster project initiation.

- Ultra-thin material handling and cutting: Laser cutting excels at processing extremely thin sheets of mu-metal with precision and minimal distortion.

- Multiple iterations: Design changes can be implemented quickly, making it easy to refine and perfect components over several cycles.

- High precision of complex geometries: The process delivers clean, accurate cuts even on the most challenging geometries, ensuring consistency and quality in every part.