Laser Cut Moly-Rhenium Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

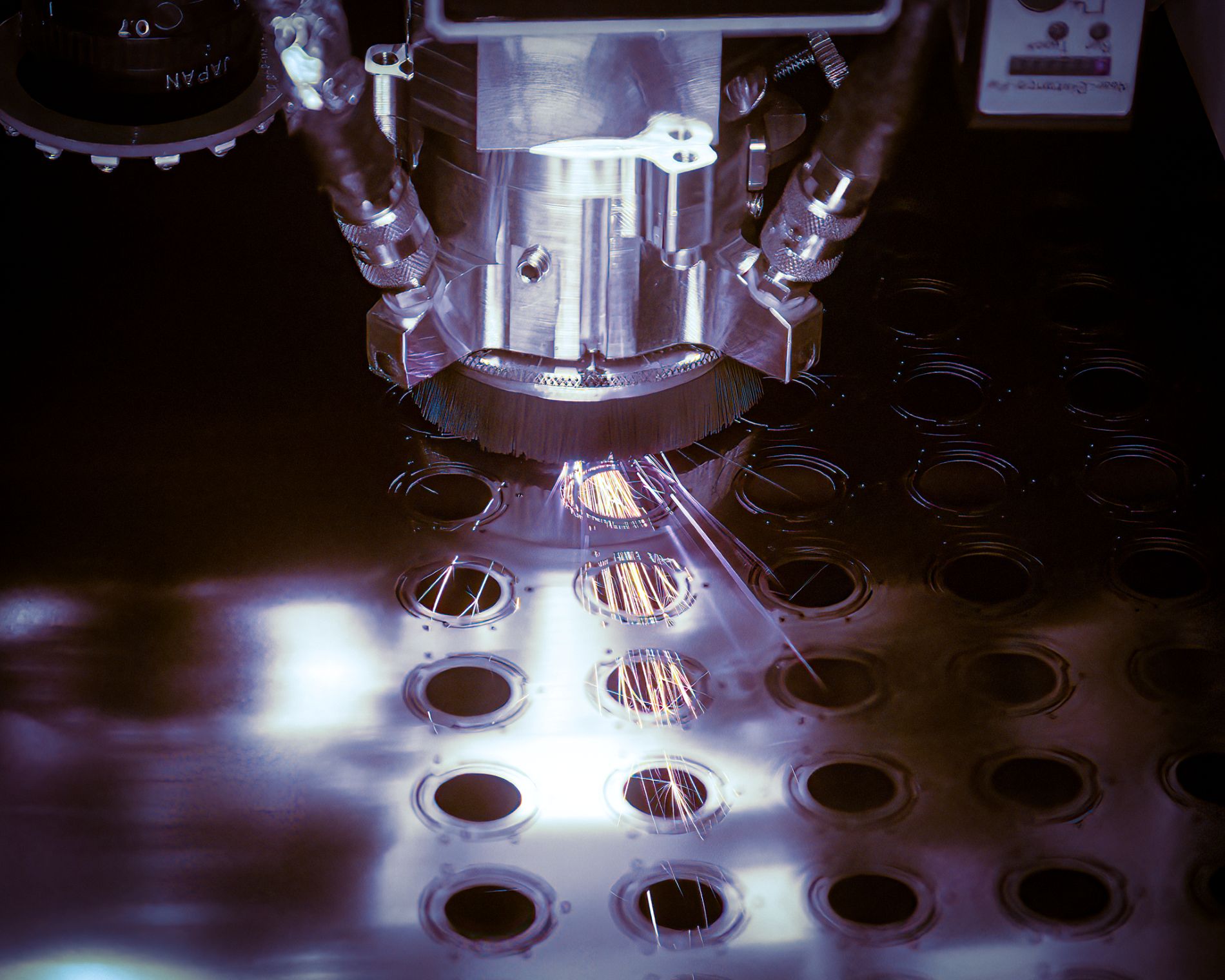

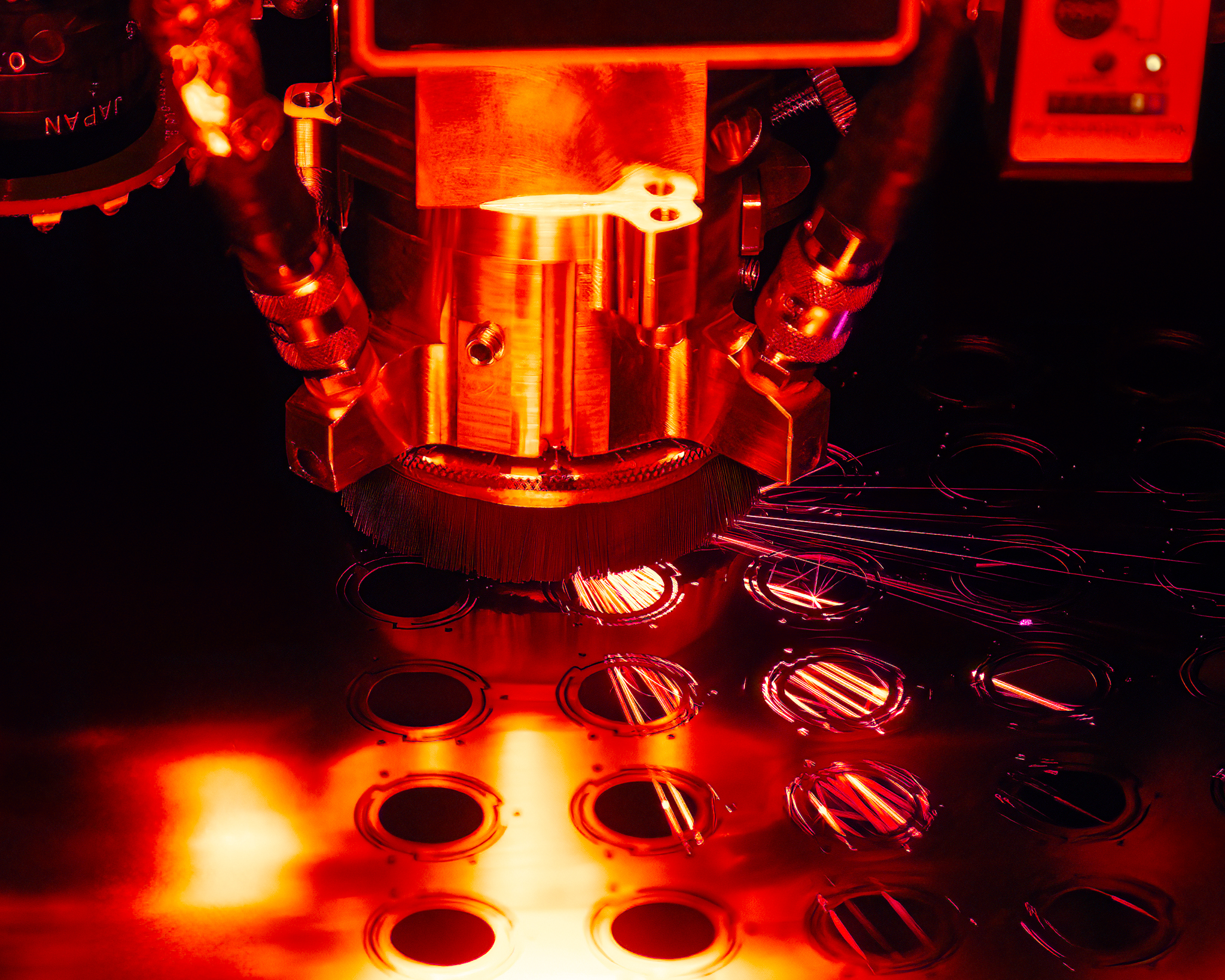

If you have been searching for a solution for your new concept or design using moly-rhenium, A-Laser may be able to help. Laser cutting of thin gauge metal alloys is widely used due to its ability to create complex shapes that other methods cannot achieve on thin materials. Laser technology now supports advanced manufacturing across industries cutting alloys such as stainless steel, titanium, nitinol, and moly-rhenium. Moly-rhenium, though less commonly known, offers high strength, a high melting point, and improved ductility, making it valuable in medical, aerospace, and semiconductor applications. For more information on moly-rhenium, refer to the following Q&A or contact A-Laser with additional questions.

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Moly-rhenium?

By utilizing UV (ultraviolet) and Fiber laser systems, A-Laser manufactures moly-rhenium components from ultra-thin foils in thickness of 1-8mils to sheets in thickness from 10 to 20 mils, with tolerances being held to +/- .5mils to 1mil for thin foils, to tolerances of +/- 1mil to 2mils for thicker sheets. Note: Each design will have a set of factors that can affect the tightest tolerance possible.

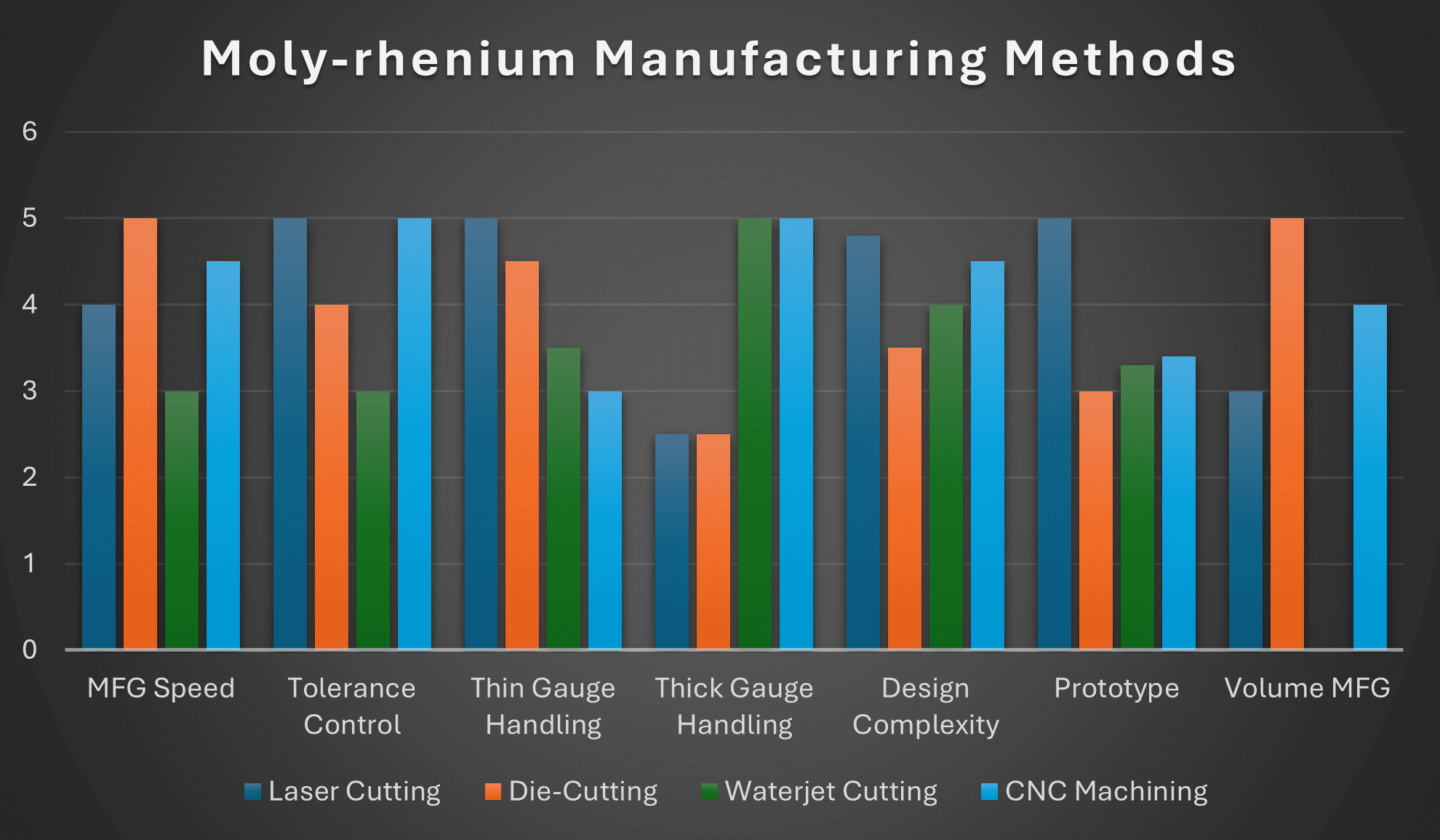

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Moly-rhenium?

Deciding on the best manufacturing method for Molybdenum-Rhenium (Mo-Re) components comes down to balancing precision, material thickness, edge quality, and cost/volume. Moly-rhenium (Mo-Re) is a refractory metal alloy and it’s incredibly hard, high-melting point makes traditional cutting methods challenging. For flat, precision components, laser cutting generally offers the best combination of speed and high-detail capability, but other methods may be better for specific needs. Here is a comparison of the key methods:

If your part is flat and requires high precision, Laser Cutting offers the best balance of speed, precision, and complexity handling for Moly-Rhenium.

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Moly-rhenium Cut foils?

When laser cutting Moly-Rhenium (Mo-Re) foils, material properties are critical to final part quality.

Reflectivity: A powerful laser is required to overcome Mo-Re’s high reflectivity and reach melting point. High reflectivity reduces effective cutting energy, often causing incomplete cuts or a wider Heat-Affected Zone (HAZ). This results in rougher edges and dross sticking to the bottom, as well as looser tolerances due to slower cutting speeds and higher power use. Fiber lasers are usually favored for their efficient absorption by metals.

High Thermal Conductivity: Rapid heat spreading increases power needs and risks thermal distortion, especially in thin foils. Edge warping and loss of flatness can occur, impacting both finish and dimensional accuracy. Precise control of cutting speed is crucial to balance complete removal with minimal thermal damage.

Softness and Hardness: Traditional machining causes excessive tool wear due to the alloy’s strength, but laser cutting avoids this with its non-contact process. Rhenium’s ductility promotes cleaner edges and prevents brittle fractures, allowing for smoother kerfs and tighter, more predictable tolerances.

What Edge Quality Can Be Expected When Laser Cutting Moly-rhenium? Are Burrs or Heat-Affected Zones (HAZ) Present?

Experience in laser cutting metal alloys like moly-rhenium has a big impact on the outcome of the finished part. By making the adjustments to the laser parameters, CAD file and knowing how the moly-rhenium will react, the expected edge quality will be of high. Post processing is available to remove and micro burrs from the cut edge.

What Are the Benefits of Laser Cutting Moly-rhenium?

When working with a high-performance refractory alloy like Molybdenum-Rhenium precision is paramount. Laser cutting isn’t just a viable method; it’s the superior engineering choice. Our high-power, non-contact fiber laser process directly solves the challenges of Mo-Re’s hardness and high melting point, ensuring sub-micron accuracy that traditional tooling simply can’t match. We deliver superior tolerance control and a remarkably clean edge quality by precisely managing thermal effects and eliminating tool wear. This capability means you get complex, intricate components with an optimized finish, accelerating your project from rapid prototyping to reliable, high-volume production without compromising material integrity.