Laser Cut Mica Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Mica is a natural occurring silicate mineral that has properties of thermal stability, chemical inertness, and excellent electrical insulation. Natural mica sheets can be inconsistent and fragile, so it needs to be processed into stable formats that make it ideal for manufacturing. Once these engineered sheets are made mica is particularly suitable for laser cutting of precisely cut geometries. Mica sheets can be as thin as 25-100 microns and mica paper combines pulverized flakes with a binder that forms a flexible dielectric material. Laser cutting services, such as offered by A-Laser, welcome opportunities to produce mica components with tight tolerances and high quality, that other methods cannot produce. Using ultra-violet laser systems, with a 355nm wavelength and beam diameters of 20microns, mica foils, paper, and laminates are made with minimal HAZ(Heat Affected Zones). For insight into laser cut mica, the following questions and answers are provided below.

More Than One Method

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Mica sheets?

Cutting thin mica sheets requires methods that will not damage this delicate material. Laser cutting being a non-contact process is ideal, however other methods can still be used and considered depending on factors such as thickness, design, and quantities. The following table is a comparison of these methods.

| Feature | Laser Cutting | Die-Cutting | Waterjet Cutting | CNC Machining |

|---|---|---|---|---|

| Process | Uses high energy laser beam. 10-200 Watts typical. | Uses a steel rule die and a press to stamp out parts. | Uses a high-pressure stream of water, often mixed with an abrasive (like garnet), to erode material. | Uses a rotating cutting tool (end mill, router bit) guided by computer control to remove material. |

| Speed | Fast for intricate, complex designs. | Very fast for mass production once the die is made. | Generally slower than laser or die-cutting for thin material. | Will be slower on blocks of mica. Control needed. |

| Precision & Tolerance | High; excellent for intricate shapes and small features. | Moderate; dependent on the die quality and material thickness. | Very High; excellent for complex and intricate shapes. | Very High; excellent for precise dimensions and 3D features (if applicable). |

| Edge Quality | Can produce a clean, smooth edge, but may have slight discoloration (Heat-Affected Zone/HAZ) on cut edge. | Clean, but may have slight burrs or fractured edges depending on mica type. | Clean and smooth; no burrs or dross, and no thermal impact. | Clean, but can cause chipping or delamination if not done with care; requires a sharp tool. |

| Set-Up | No tooling required; quick setup from digital files. | High initial cost and time to create the die. | No tooling required; quick setup from digital files. | Requires selection of specific cutting tools (end mills) which wear down. |

| Best For | Thin sheets of Mica (less than 20mils thick) Prototypes or low-volume, intricate parts where speed is critical. | High-volume production of simple, identical shapes. | High-precision, complex parts, especially for thicker mica, where material integrity is paramount. | Complex 3D features (pockets, bevels) or parts where a specific cut profile is needed. |

Mica’s Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Mica Sheets?

Mica’s unique material characteristics significantly influence how it’s cut. Its softness and layered structure make it susceptible to delamination during mechanical cutting processes like die-punching, especially on thicker sheets, which can compromise edge quality and dimensional tolerance. However, this same layered structure, known as basal cleavage, is a key property that allows it to be split into incredibly thin sheets. Additionally, mica’s low thermal conductivity and high heat resistance make it an excellent thermal insulator, which is generally a benefit in cutting, as it doesn’t deform or combust easily under heat. However, its reflectivity can pose challenges in laser cutting, as the laser beam can bounce back and damage the equipment’s optics. Adjusting the laser parameters as mentioned earlier significantly reduces thermal concerns and promotes high edge quality.

Tale of Tolerance

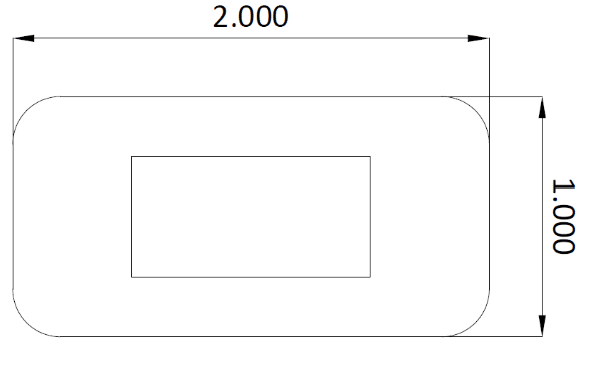

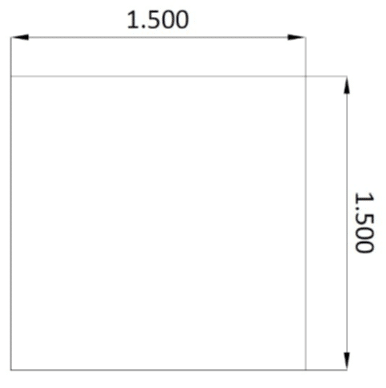

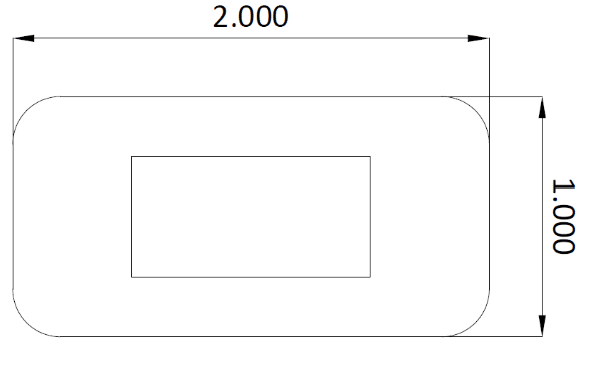

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Mica?

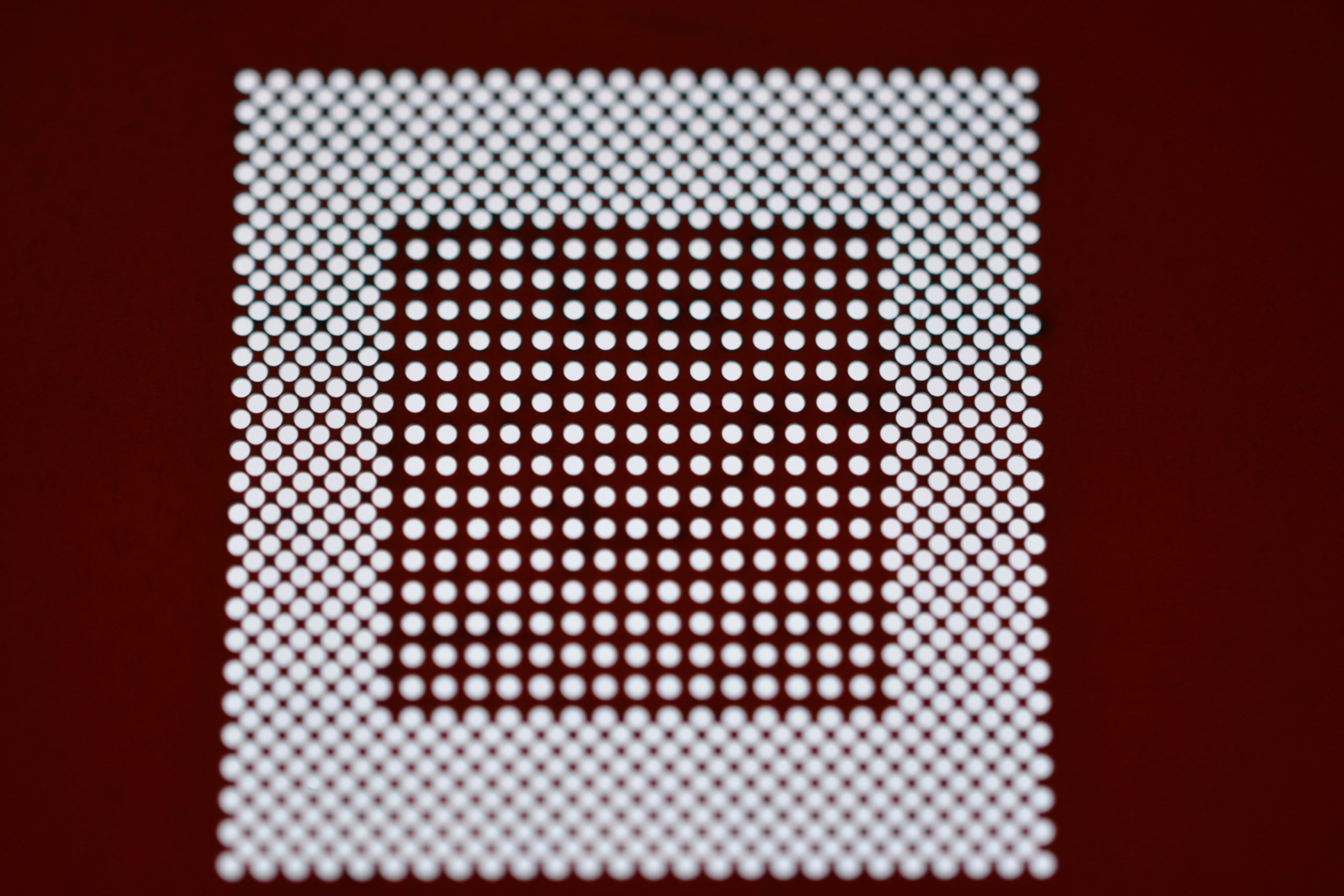

When laser cutting mica sheets between .5mils and 10 mils thick, you can expect tolerances to be held within a +/- 1mil for most projects. By using UV (ultraviolet) laser systems, the beam of 20microns is controlled parameters such as power, frequency, speed of travel (along the laser path), passes or cycles and focus. These parameters and others make up the “laser tool” which is unique to each project.

Quality Of the Cut Edge

What Edge Quality Can Be Expected When Laser Cutting Mica? Are Burrs or Heat-Affected Zones (HAZ) Present?

Following up from the characteristics of mica and how they can influence the quality of the laser cut part, specifically on edge quality, is a challenge that is solved through years of experience. Although every job is different and brings along factors that need to be adjusted to, for mica precision components these results will be generally seen:

Burrs: Generally, laser cutting can achieve burr-free cut edges on thin mica sheets. The non-contact nature of the laser minimizes the chance of mechanical burrs common in die-cutting.

Heat-Affected Zone (HAZ):

- A HAZ is typically present due to the high-heat, thermal cutting process.

- This HAZ can manifest as slight discoloration (charring) or smoke residue on the cut edge and surrounding area.

- On natural, brittle mica, the heat and subsequent cooling can cause microscopic cracks, chipping, or slight delamination near the edge. This mica is typically not used in critical use laser cut components.

Edge Quality:

- The edge is usually smooth and precise, capable of creating very intricate contours.

- Optimal parameter settings (speed, power, assist gas) are critical; too much heat will significantly degrade the edge quality.

- For the best results, resin-bonded mica (micanite) is often preferred over natural mica because the resin binder helps hold the layers together, resulting in a cleaner, less-cracked edge.

Concluding Thoughts

What Are the Benefits of Laser Cutting Mica?

Laser cutting technology is a key part of many supply chains throughout high technology driven industries. The ability of lasers to provide consistent and reliable precision of flat components made from challenging materials such as mica, continue to place this manufacturing method in high regard. Mica, with its layered structure, is prone to delamination and breakage when mechanical forces are applied. Mica’s low thermal conductivity and high heat resistance make it an excellent thermal insulator, which is generally a benefit in cutting, as it doesn’t deform or combust easily under heat. This promotes the use of laser cutting machines to overcome many manufacturing concerns. With the ability to support R&D and prototypes and move rapidly to production, laser cutting service providers welcome your mica projects and we at A-Laser will be very happy to discuss further how we can be of service.