Laser Cutting Melinex Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

When you need a thin, stable substrate that combines excellent tensile strength, thermal resistance and surface treatability, Melinex polyester film may be the solution you need. Our laser cutting process is tuned to Melinex’s low-mass, heat-sensitive nature to produce crisp, burr-free edges, delicate internal features and repeatable tolerances whether you’re prototyping or scaling to production. As a biaxially oriented PET film, it resists heat, chemicals, and stretching, maintaining tight tolerances even in intricate or micro-scale designs. Melinex, which is a trademark of DuPont-Teijin, is made in ultra-thin films ranging from 12um to 350um, so there are numerous options to be processed by laser technology. For further insight into laser cutting Melinex, the following Q&A are provided. We hope that the information assists you with selecting the right thickness and manufacturing method.

Laser Cutting and Tight Tolerances

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Melinex?

With our experience in cutting PET material such as Melinex, the choice of laser technology is UV or ultraviolet systems. With a beam diameter of 20um, very small features with smooth radii and sharp corners are possible. This non-contact process holds material flat using a vacuum bed and can achieve tolerances from +/- .5mils to +/- 2 mils. The thickness of the Melinex and the complexity of the cut design are factors that affect how accurate the feature and positional tolerance is.

Which Method Is Best?

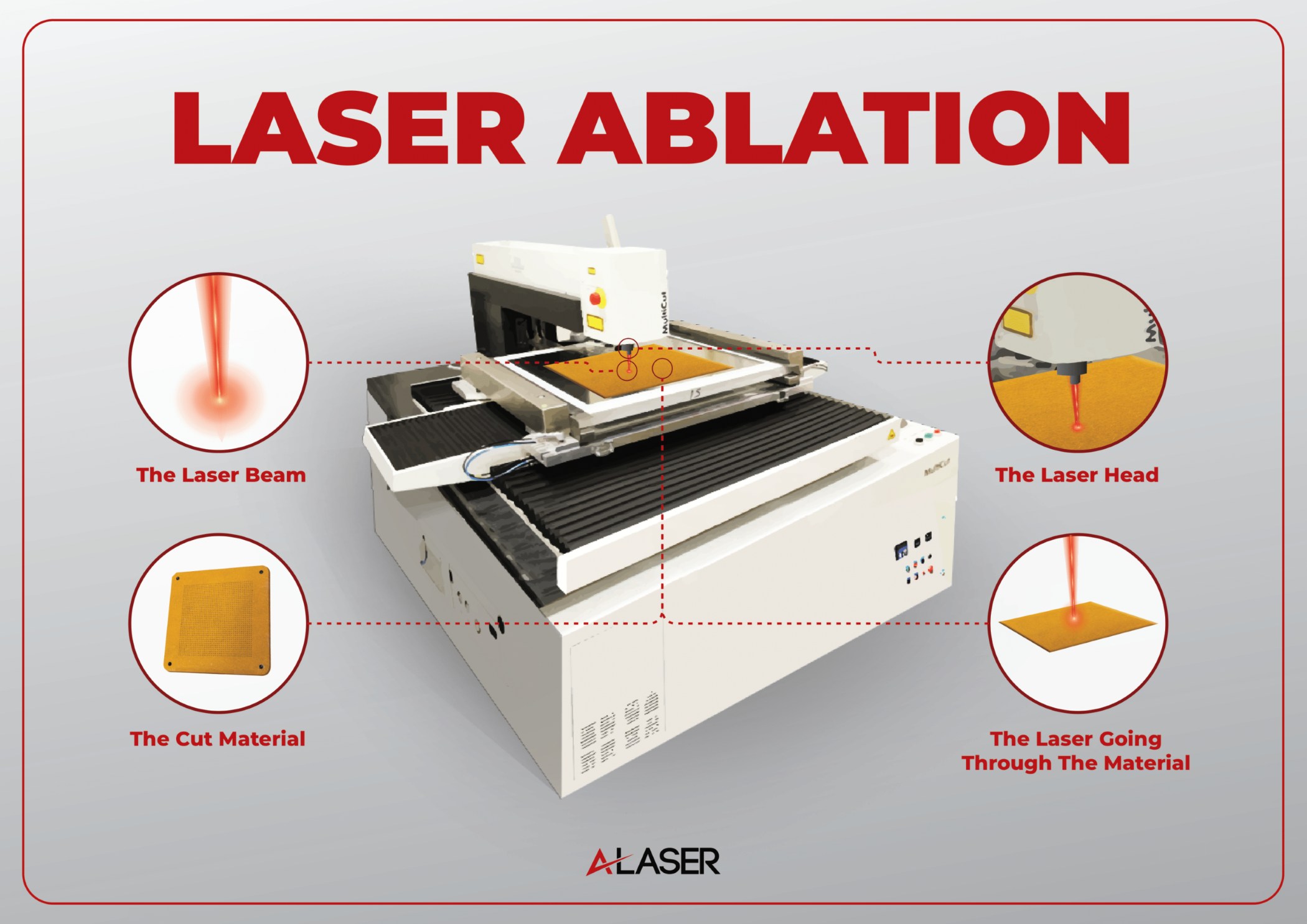

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Melinex?

| Process | Key Advantages | Limitations | Typical Tolerances | Best Uses |

|---|---|---|---|---|

| Laser Cutting | No tooling needed; precise, clean edges; ideal for intricate geometries and quick prototyping | Can cause slight HAZ if parameters aren’t optimized; slower for very large runs. | +/- .5mil to +/- 2mils | Prototypes, small/medium runs, detailed shapes, quick design changes. |

| Die-Cutting | Fast, repeatable, economical for volume; excellent edge quality on flexible films. | Requires tooling; limited for complex internal cuts. | +/- 4mils to +/- 12mils | High-volume production of gaskets, labels, and adhesive parts. |

| Waterjet Cutting | Cold process, no thermal effects or edge discoloration. | Not ideal for thin flexible films (flutter, fixturing challenges). | +/- 1 mil to +/- 8mils | Thicker laminated stacks or when heat must be avoided. |

| CNC Machining | Can process thicker PET sheets; good dimensional control. | Mechanical contact can deform or tear thin films. | +/- 1mil to +/- 6mils | Rigid PET sheet components, prototypes requiring mechanical features. |

When it comes to Melinex polyester film, laser cutting stands out for precision and flexibility, making it ideal for intricate designs, rapid prototyping, and small to medium production runs. Die-cutting shines in high-volume applications, delivering consistent edges quickly once tooling is set up, while waterjet and CNC machining are better suited for thicker or multi-layered components where thermal or mechanical effects must be minimized. By understanding each method’s strengths, you can choose the process that balances accuracy, speed, and cost for your specific Melinex parts.

Is It Shiny, Hard, or Soft?

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Melinex?

The material characteristics of Melinex generally support high-quality edges and tight tolerance control, especially during laser cutting. Its low reflectivity ensures that the laser energy is efficiently absorbed, leading to cleaner, sharper edges and more consistent cutting, which is critical for holding tight tolerances often asked of laser manufacturing. With low thermal conductivity of Melinex means that heat from the cutting process is not quickly conducted away, but it also allows for a localized cut, minimizing the Heat-Affected Zone (HAZ) and edge discoloration. This helps in preserving edge quality and dimensional stability. Manufactured from thin films or sheets, the components will be soft and flexible but can make the material susceptible to warping or shifting if not properly secured during cutting. From experience we understand this could negatively affect tolerance control and overall dimensional stability. As a non-contact cutting method such as laser cutting, we adjust according to each project’s requirements.

Edge Cut Results

What Edge Quality Can Be Expected When Laser Cutting Melinex? Are Burrs or Heat-Affected Zones (HAZ) Present?

Although we briefly mentioned HAZ in the previous paragraph it is a factor that is of great importance to note when considering laser technology and a factor to be addressed for any laser cutting service provider. HAZ can affect the edge quality and produce burrs if the laser parameters are not adjusted properly. Adjustments are made such as to laser power, laser frequency, laser cutting speed, laser passes or cycles, laser focus and others. Adjustments like these are done similarly to all materials to ensure the optimum quality is provided.

Something To Think About

What Are the Benefits of Laser Cutting Melinex?

It is not a true or fair comparison of laser cutting technology over other methods like CNC machining, die-cutting or waterjet cutting because each of these manufacturing techniques offers reliability and precision within their respective capabilities. What is a more answerable question is “why would your project benefit from laser cutting technology?” Since we would have established that that Melinex films or thin sheets would cut using UV laser systems, and accurate to +/- 1mil, this allows for potential more complex shapes and finer features, that you cannot achieve in thin films with other processes. Laser set up is quick with no additional tooling. Development projects (prototypes and small test runs) can ramp up almost seamlessly to becoming a partner in a supply chain. Laser cutting is a great solution for many industries including semiconductors, battery energy, medical devices, wireless communications, optics, sensors and many more sectors requiring high reliability. With many variables to consider, we at A-Laser will be happy to discuss and review your project and determine if laser cutting is the right path.