Laser Cut Kyflon Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

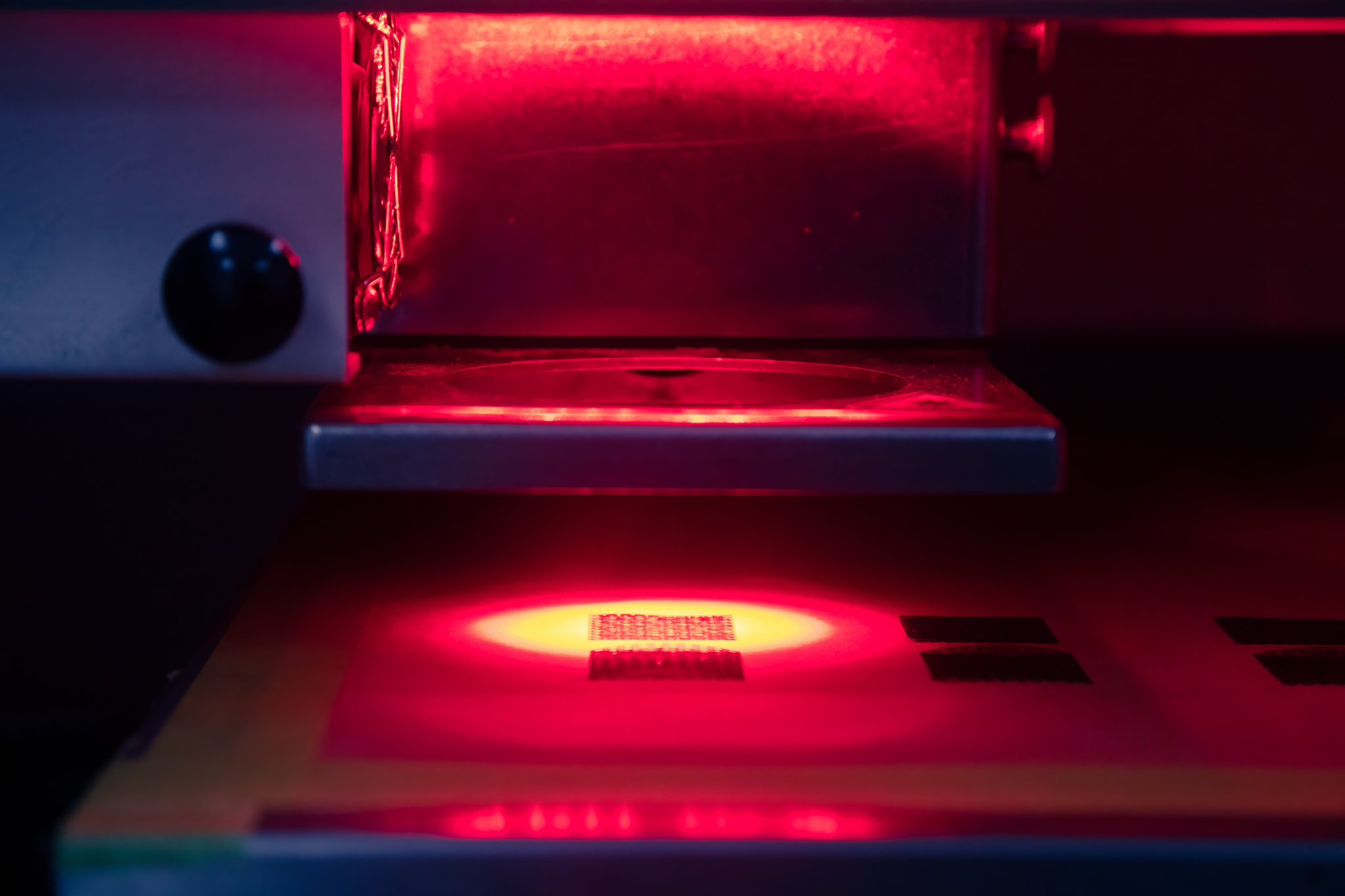

Kyflon™ is a perfluoroelastomer engineered for applications where ordinary seals fail in controlling harsh chemicals and as a barrier for high heat. While traditionally shaped by use of molding or die-cutting, today laser cutting technology is available in manufacturing Kyflon parts. This method is opening new possibilities for this high-performance material with components made to the tightest margins of reliability. Laser cutting’s ability to create intricate geometries with laser services, support start-ups with prototypes and R&D to becoming a partner with established companies for volume production. For mechanical engineers, laser cut Kyflon offers options for manufacturing that can reshape the way we think about seals and gaskets and not just as static parts. This precision manufacturing produces components used in pumps, valves and other applications where high temperatures and chemicals are present. For additional insight, the following questions and answers about Kyflon and laser manufacturing are provided.

Manufacturers Compete

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Kyflon?

When making precision components from Kyflon, there are constraints and trade-offs depending on the manufacturing method. Perfluoroelastomers like Kyflon are elastomeric (rubbery), not rigid like metals or hard plastics, so certain cutting and machining methods behave differently. Here are key methods, with pros/cons specific to materials like Kyflon.

| Method | Best Used For | Challenges/Limitations |

|---|---|---|

| Laser Cutting | Best for thin sheets or prototyping, for certain elastomers, lasers can cleanly ablate material and get fine detail and tight tolerances. | Laser cutting risks emission of toxic gases or corrosive by-products, especially if there is no proper ventilation. HAZ or heat affected zones may discolor the cut edge and affect the materials properties. |

| Die-Cutting | Very good for high volume of repeated shapes like gaskets, O-rings, simple flanges. Fast and cost effective once tooling is made. | With soft elastomeric materials, the die may compress or distort the material during cutting. Thickness variations, spring-back, deformation can lead to tight tolerances being harder to maintain. |

| Waterjet Cutting | Good option for moderate to low volumes, or prototype/custom parts. Because it’s non-thermal (i.e. no heat generated by the cutting medium itself), it avoids altering the material via heat. | Under high-pressure water elastomeric materials may deform or flex; resolution is limited compared to rigid materials. |

| CNC Machining | For thicker and rigid or semi-rigid shapes, CNC allows precise three-dimensional features. For elastomeric parts, CNC turning or routing of discs, rings, etc., is possible with good precision. | Machining can be difficult, with tearing or deformation under cutting tools. Tight tolerance is challenging and may be hard to achieve. |

Measuring Up

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Kyflon?

When laser cutting Kyflon, the tightest tolerances typically achievable fall within the range of +/- 1 mil to +/- 2mils, though results depend on part geometry and thickness. Because Kyflon is soft and elastomeric, the challenge lies not in the laser’s precision but in controlling edge deformation and the material’s natural tendency to “spring back. With carefully tuned laser parameters and fixturing, engineers can achieve crisp edges and repeatable dimensions that rival or surpass mechanical methods, especially for intricate profiles where every fraction of a millimeter matters.

Factoring Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Kyflon?

Kyflon’s characteristics make it behave differently from metals or rigid plastics when it meets a cutting process. Being soft and elastomeric the edge quality and control of tolerance need to counter Kyflon’s characteristics. Laser cutting Kyflon and similar materials are a challenge. The success of a project using this material with laser technology requires a balance of parameter controls to counter the tendency of the materials traits. The table below and how these traits can affect the manufacturing process.

| Material Trait | Effect On Laser Cutting/Adjustments Made | Effect on Edge Quality and Tolerance | Laser Adjustments |

|---|---|---|---|

| Softness | Material flexes. | Features may distort. | Lasers hold materials under vacuum. |

| Thermal Conductivity (Low) | Heat lingers instead of dispersing. | Risk of melting, glazing, or slight edge deformation during laser cutting. | Parameters of power, cut speed, cycles and others are adjusted. |

| Reflectivity (Low) | Laser energy is absorbed efficiently. | Improves precision but increases chance of localized thermal damage. | Parameters used for thermal concerns are balanced for optimum cut. |

| Elastic Recovery | Material “springs back” after being cut. | Features may shift slightly from intended dimensions. | Adjustments to the cut program to compensate for shift. |

| Chemical Resistance | Resists degradation from cutting fluids or processes. | Helps preserve edge integrity post-cutting, especially in harsh environments. | No cutting fluids used, Edge quality confirmed through inspection. |

Controlling Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Kyflon? Are Burrs or Heat-Affected Zones (HAZ) Present?

The edge quality of Kyflon when laser cut is generally smooth and precise, with no burrs since the material is an elastomer rather than a metal. However, because Kyflon has low thermal conductivity, localized heat can result in HAZ (Heat Affected Zone), forming on some features. This would look like a slight glazing and darkening of the cut edge. Surface hardening may occur if parameters aren’t finely tuned. With proper control of the lasers power, number of cycles, and assist gases, these effects can be minimized, yielding clean, reliable edges that preserve the material’s sealing performance.

Laser Advantages

What Are the Benefits of Laser Cutting Kyflon?

The benefits of laser cutting Kyflon go beyond a process of simply shaping a tough material, they highlight why laser technology has become a cornerstone of modern precision manufacturing. Unlike mechanical methods that press or tear at elastomers, the laser’s non-contact beam preserves Kyflon’s sealing integrity while producing intricate geometries that would be difficult or costly with tooling. It’s also a reminder of how efficient laser cutting can be at creating tight kerfs and reducing waste of this premium material. Tolerances stay repeatable and prototypes can transition seamlessly into production without retooling delays. For engineers, the value lies not just in what’s cut, but in how the process itself turns a challenging elastomer into a precisely engineered component ready for critical applications.

Concluding Notes

Precision parts made by using laser cutting machines are a great asset to any project. Made from materials such as Kyflon, the benefits can far exceed the quality of other manufacturing methods. Laser cutting techniques however are not the sole solution for all precision cutting projects. Manufacturing has way of sorting through the details and factors surrounding each new opportunity. The best way usually is the method of choice. Challenging materials give manufacturers the opportunity to learn and by doing so, more doors are opened, and possibly new applications arise. Kyflon and its use is a great solution for many industries and using laser cutting technology is one of the options available for reliable and precision-controlled parts.