Laser Cut Kovar Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Back in 1936, Kovar metal alloy was patented to overcome the challenges of sealing metal and glass. A needed solution for the developing electronics industry, Kovar’s ability to contract and expand at a rate like glass, created what is called a hermetic seal. These hermetic seals are vital for electronics and fields such as aerospace and defense, medical devices and scientific applications for vacuum tubes, hermetic connectors, sensors, integrated circuits and many more. Fabricating these highly critical components is supported by laser cutting technology in ways that other methods cannot. There is much to learn about the manufacturing of Kovar flat components and laser cutting so the following questions and answers are provided about this combination of material and manufacturing.

The Tale of Tolerance

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Kovar?

For cutting Kovar, the tightest tolerances a laser can maintain are as low as ± .5 mils to +/- 1mil, but this is highly dependent on the laser technology used, material thickness, and part geometry. To achieve the best results, one must consider the specific type of laser, as they each offer a different balance of precision, speed, and cost.

Fiber Lasers

- They offer a great balance of speed and precision for a wide range of materials, including Kovar. Their infrared (IR) wavelength, typically around 1 micron, is well-absorbed by metals. However, the heat generated by fiber lasers can cause a heat-affected zone (HAZ). Typical tolerances with a fiber laser are in the range of +/- 1mil to +/- 3mils.

UV Lasers

- Ultraviolet (UV) lasers, also known as “cold lasers,” operate at a much shorter wavelength (around 355 nm). This allows for extremely small focal points and minimal heat input into the material. This results in an almost non-existent HAZ, making UV lasers ideal for cutting sensitive materials like Kovar without inducing thermal stress or altering its properties, key to achieving tolerance of +/- .5mils to +/- 1mil for thin materials.

Femtosecond Lasers

- As an ultrafast laser, it delivers energy in pulses that are incredibly short in the order of quadrillionths of a second. This eliminates the HAZ and any thermal stress. While incredibly precise, allowing for tolerances potentially even tighter than UV lasers. They are typically reserved for the most critical, high-value applications where no other technology can meet the strict requirements.

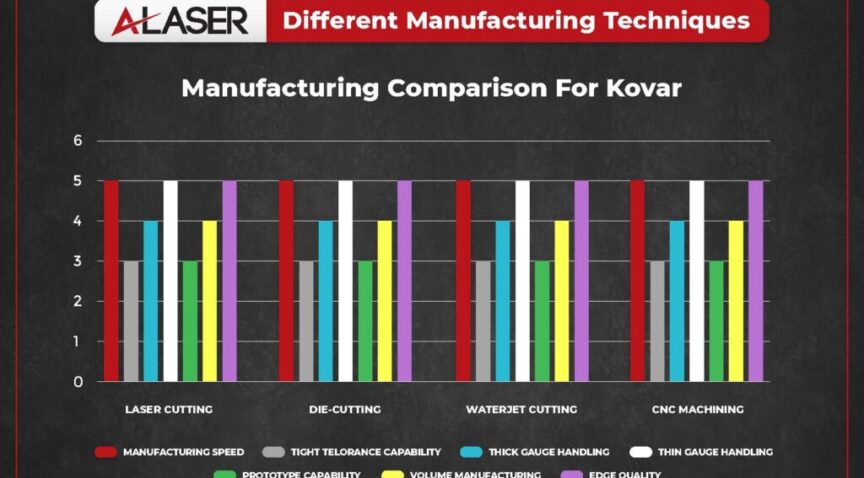

Different Manufacturing Techniques

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Kovar?

How the best method for cutting Kovar depends on your specific needs, such as the required tolerance, part thickness, and production volume. Here is a breakdown of how the four methods compare across key factors, with a bar graph for easy comparison.

Manufacturing precision parts is done by the methods listed above and other methods with each having areas of expertise for many industries and niche applications. The comparison is a general idea and project factors determine the best course of action.

Focused On the Edge

What Edge Quality Can Be Expected When Laser Cutting Kovar? Are Burrs or Heat-Affected Zones (HAZ) Present?

When laser cutting Kovar, the edge quality is generally high, but because it’s a thermal process, both burrs and a heat-affected zone (HAZ) are typically present to some degree. However, the extent of these can be expertly controlled and minimized.

- Burrs: Burrs are small pieces of molten or torn metal that can re-solidify along the cut line. While laser cutting Kovar can leave some burrs, these are often very small and easily removed in a secondary process like tumbling or a light deburring pass. The key to minimizing them is precisely controlling the laser power, cutting speed, and the pressure of the assist gas.

- Heat-Affected Zone (HAZ): The HAZ is the area of the material adjacent to the cut that has been altered by heat but hasn’t melted. Given Kovar’s low thermal conductivity, heat doesn’t dissipate quickly, which can lead to a more pronounced HAZ. The presence of a HAZ is the main concern when using a thermal process for sensitive materials like Kovar.

Advanced lasers and optimized settings minimize a heat-affected zone (HAZ) and burrs when laser cutting Kovar. Ultrafast lasers, such as femtosecond lasers, prevent heat transfer by vaporizing the material instantly, resulting in a cleaner cut with a virtually non-existent HAZ. For standard industrial ultraviolet and fiber lasers, a clean edge is achieved by adjusting cutting speed and using inert gases to prevent oxidation and to remove molten material.

Challenging Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Kovar?

Manufacturing precision parts requires focus on the characteristics of the intended material and this is true regarding the use of laser cutting machines. Although laser technology is a “non-contact” process, the beam that will ablate the material along with the power used and the number of cycles needed to cut, need to adjust to the materials characteristics. The table is an indication of the challenges of these characteristics of Kovar.

| Characteristic | Effect On Edge Quality | Effect On Tolerance Control |

|---|---|---|

| Reflectivity | It can lead to inconsistencies and melt splatter on the cut edge. | Poorly absorbed energy makes maintaining tight tolerances challenging. Modern lasers and ultrafast lasers are better at overcoming this. |

| Softness (In Annealed State) | Laser ablation on softer metallic materials requires adjustment of parameters to maintain edge quality and reduce HAZ. | Making it challenging to maintain precise dimensions and leading to less consistent part geometry. |

| Work Hardening | If not controlled can lead to a harder, more brittle layer on the surface, making subsequent cuts difficult and leading to chipped edges. | The hardening can lead to dimensional inaccuracies of the cut edge and a loss of tolerance. |

| Thermal Conductivity | Kovar has a relatively low thermal conductivity, which means heat from a laser or cutting tool doesn't dissipate quickly. It can lead to pronounced HAZ and discoloration along the cut edge. | Heat buildup can cause the part to temporarily expand with significant dimensional distortion. To compensate, laser tool adjustments of power, laser cycles, dwell time and others, are needed. |

Key Points

What Are the Benefits of Laser Cutting Kovar?

Laser cutting Kovar offers a powerful combination of precision, speed, and design flexibility that is ideal for producing intricate components for the electronics and aerospace industries. Unlike mechanical methods, laser cutting machines provide a non-contact cutting process that minimizes physical stress on the material, which is crucial for Kovar’s precise thermal expansion properties. The ability to create complex geometries and very small features that would be impossible with traditional machining, combined with fast processing times, allows for rapid prototyping and high-volume production of the hermetic seals and electronic packages for which Kovar is known. The primary benefit lies in its ability to achieve demanding specifications without compromising the material’s critical properties.

Final Thoughts

In essence, Kovar’s unique value stems from its precisely controlled coefficient of thermal expansion, making it the ideal material for creating robust, hermetic seals with glass and ceramics in critical applications like electronics, aerospace, and medical devices. By strategically choosing the right manufacturing method—from the high-volume efficiency of die-cutting to the unparalleled precision of ultrafast lasers—manufacturers can leverage Kovar’s specific characteristics to meet the increasingly demanding requirements of modern technology.